KIA Niro: Water pump Repair procedures

Removal

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to shut off the high voltage circuit according to the "High Voltage Shut-off Procedures" before doing any work related with the high voltage system to avoid serious electrical injuries.

- Shut off the high voltage circuit.

(Refer to Engine Mechanical System - "High Voltage Shut off Procedure")

- Remove the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

- Drain the coolant.

(Refer to Cooling System - "Coolant")

- Remove the drive belt.

(Refer to Drive Belt System - "Drive belt")

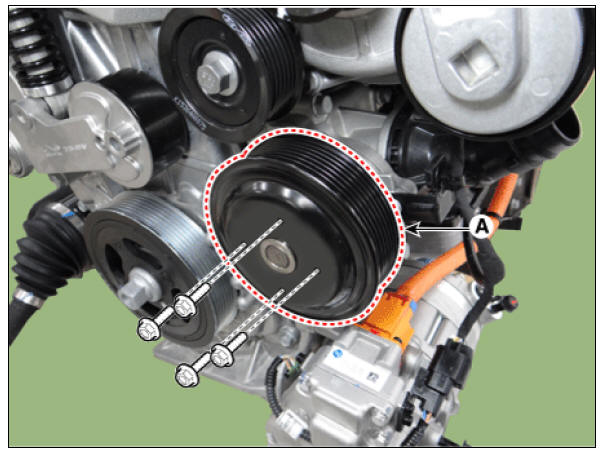

- Separate the water pump pulley (A).

Tightening torque : 9.8 - 11.8 N*m (1.0 - 1.2 kgf*m, 7.2 - 8.7 lb*ft)

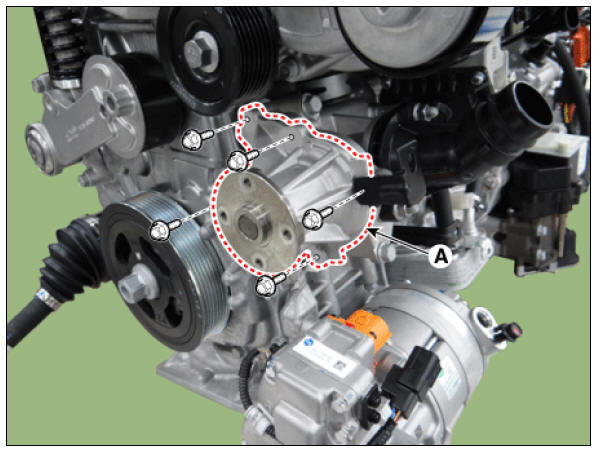

- Remove the water pump (A) with water pump pulley.

Tightening torque : 7.8 - 11.8 N*m (0.8 - 1.2 kgf*m, 5.8 - 8.7 lb*ft)

- Remove the water pump gasket (A).

- Install in the reverse order of removal.

Warning

Install a new water pump gasket.

- Fill the engine coolant.

(Refer to Cooling System - "Coolant")

- Start the engine and check for leaks.

- Recheck the coolant level.

Water Pump Cover

- Remove the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

- Drain the coolant.

(Refer to Cooling System - "Coolant")

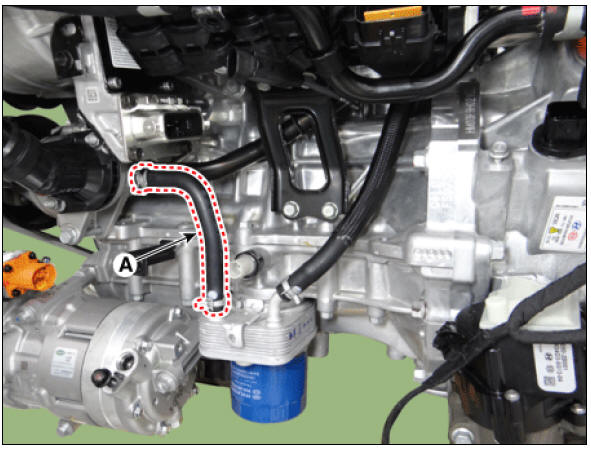

- Disconnect the coolant hose (A).

- Remove the thermostat.

(Refer to Cooling System - "Thermostat")

- Remove the heater pipe.

(Refer to Cooling System - "Water Temperature Control Assembly")

- Remove the water pump.

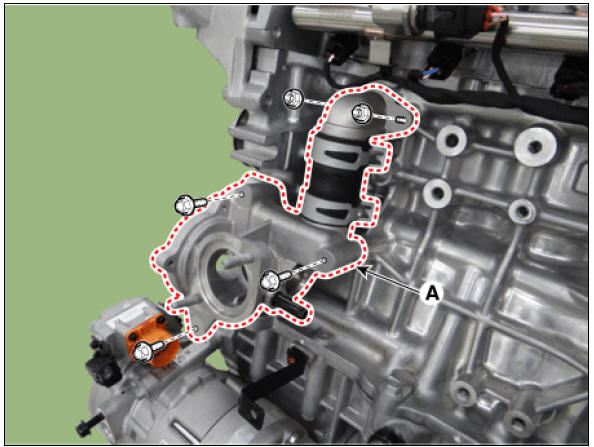

- Remove the water pump cover (A).

Tightening torque : 18.6 - 23.5 N*m (1.9 - 2.4 kgf*m, 13.7 - 17.4 lb*ft)

- Install in the reverse order of removal.

- Fill the engine coolant.

(Refer to Cooling System - "Coolant")

- Start the engine and check for leaks.

Inspection

- Check each part for cracks, damage or wear, and replace the coolant pump assembly if necessary.

- Check the bearing for damage, abnormal noise and sluggish rotation, and replace the coolant pump assembly if necessary.

- Check for coolant leakage. If coolant leaks from hole, the seal is defective. Replace the coolant pump assembly.

Warning

A small amount of "weeping" from the bleed hole is normal.

READ NEXT:

Thermostat Repair procedures

Thermostat Repair procedures

Removal and

Installation

Warning

Disassembly of the thermostat may have an adverse effect, causing

deteriorated cooling efficiency. Do not

remove the thermostat, even if the engine tends to overheat.

Remove the engine room under cover.

(R

Water Temperature Control Assembly

Water Temperature Control Assembly

Removal and Installation

Water Temperature Control Assembly

Disconnect the battery negative terminal.

Loosen the drain plug, and drain the engine coolant. Remove the

reservoir cap to help drain the coolant

faster.

(Refer to Cool

Heater Pipe | Active Air Flap (AAF) Repair procedure

Heater Pipe | Active Air Flap (AAF) Repair procedure

Disconnect the battery negative terminal.

Loosen the drain plug, and drain the engine coolant. Remove the reservoir cap to help drain the coolant faster.

(Refer to Cooling System - "Coolant")

Remove

SEE MORE:

Head-Up Display (HUD)

Head-Up Display (HUD)

The Head-Up Display is a transparent

display that projects an image of certain

information from the instrument cluster

and navigation system on the windshield

glass.

The head up display image on the

HUD screen may be invisible when:

Information on data processing

Information on data processing

Any processing of personal data through

the 999-based eCall in-vehicle system

shall comply with the personal data protection

rules provided for in Directives

95/46/EC (1) and 2002/58/EC (2) of the

European Parliament and of the Council,

and in

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us