KIA Niro: Cooling System

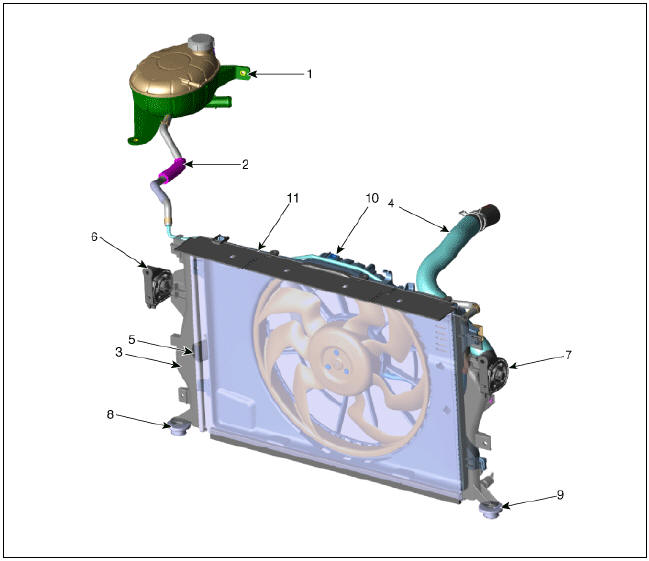

Components

- Reservoir tank

- Reservoir hose & pipe

- Radiator

- Radiator upper hose

- Radiator lower hose

- Radiator upper mounting bracket (RH)

- Radiator upper mounting bracket (LH)

- Radiator lower mounting insulator (RH)

- Radiator lower mounting insulator (LH)

- Cooling fan assembly 11. Air dam

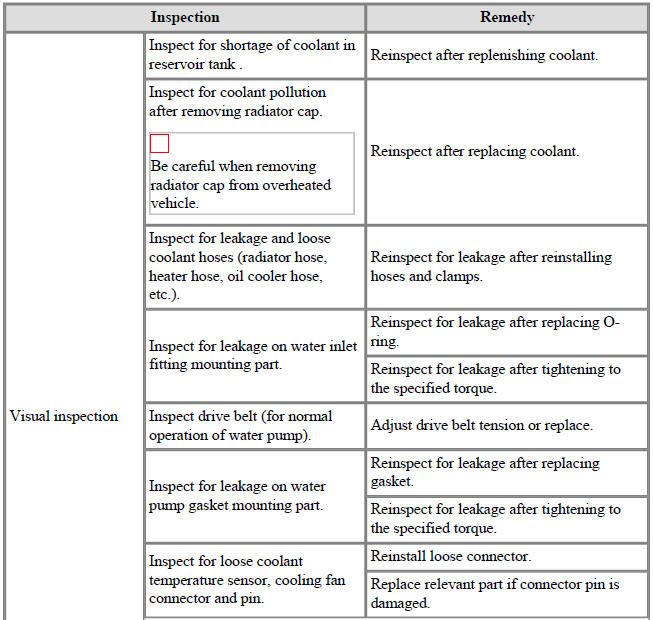

Engine Overheat Troubleshooting

Inspection : → Remedy

Visual inspection

Inspect for shortage of coolant in reservoir tank . → Reinspect after replenishing coolant.

Inspect for coolant pollution after removing radiator cap. → Reinspect after replacing coolant.

Warning

Be careful when removing radiator cap from overheated vehicle.

Inspect for leakage and loose

coolant hoses (radiator hose,

heater hose, oil cooler hose,

etc.). → Reinspect for leakage after

reinstalling

hoses and clamps.

Inspect for leakage on water inlet fitting mounting part. →

-

Reinspect for leakage after replacing Oring.

-

Reinspect for leakage after tightening to the specified torque.

Inspect drive belt (for normal operation of water pump). → Adjust drive belt tension or replace.

Inspect for leakage on water pump gasket mounting part. →

-

Reinspect for leakage after replacing gasket.

-

Reinspect for leakage after tightening to the specified torque.

Inspect for loose coolant temperature sensor, cooling fan connector and pin. →

-

Reinstall loose connector.

-

Replace relevant part if connector pin is damaged.

Inspect operation status of cooling fan.

-

Check operation status by switching ON/OFF the heater control A/C. → Check mounting status of ground cable.

Warning

Will not operate in cold ambient temperature.

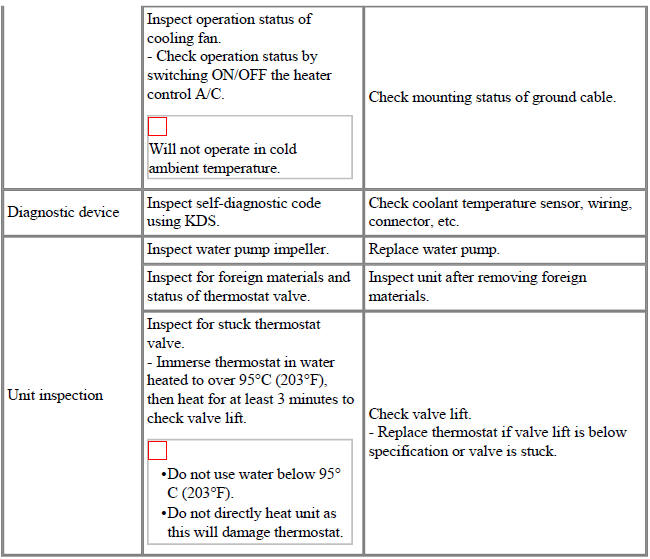

Inspection : → Remedy

Diagnostic device

Inspect self-diagnostic code using KDS. → Check coolant temperature sensor, wiring, connector, etc.

Inspection : → Remedy

Unit inspection

Inspect water pump impeller. →Replace water pump.

Inspect for foreign materials and status of thermostat valve. → Inspect unit after removing foreign materials.

Inspect for stuck thermostat valve.

-

Immerse thermostat in water heated to over 95°C (203°F), then heat for at least 3 minutes to check valve lift. →

Check valve lift.

-

Replace thermostat if valve lift is below

specification or valve is stuck.

Warning

-

Do not use water below 95°

C (203°F). -

Do not directly heat unit as

this will damage thermostat.

- Coolant Repair procedures

- Cooling Fan Repair procedures | Cooling Fan Assembly

- Cooling Fan Control Module (PWM) | Radiator

- Water pump Repair procedures

- Thermostat Repair procedures

- Water Temperature Control Assembly

- Heater Pipe | Active Air Flap (AAF) Repair procedure

READ NEXT:

Coolant Repair procedures

Coolant Repair procedures

Warning

Never remove the radiator cap when the engine is hot. Serious

scalding could be caused by hot fluid under

high pressure escaping from the radiator.

Warning

When pouring engine coolant, shut the relay box lid and be careful

not to spil

Cooling Fan Repair procedures | Cooling Fan Assembly

Cooling Fan Repair procedures | Cooling Fan Assembly

Cooling Fan Components and components location

Components

Cooling fan

Cooling fan motor

Cooling fan shroud

Air dam

Cooling fan controller (PWM)

Description

Controls the cooling fan motor voltage depending on the duty

SEE MORE:

Heater Unit Repair procedures

Heater Unit Repair procedures

Replacement

Warning

When prying with a flat-tip screwdriver or a prying trim tool, wrap

a protective tape around the related parts and the tool to

prevent damage.

Disconnect the negative (-) battery terminal.

Recover the refrigerant with a

Rear View Monitor malfunction and limitations

Rear View Monitor malfunction and limitations

Rear View Monitor malfunction

When Rear View Monitor is not working

properly, or the screen flickers, or the

camera image does not display properly,

Kia recommends visiting an authorized

Kia dealer/service partner.

Limitations of Rear View Moni

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us