KIA Niro: Clutch Actuator Assembly

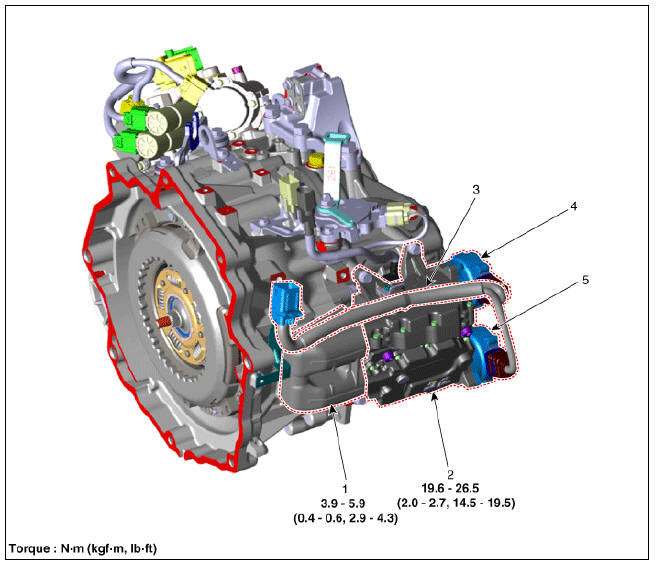

Components

- Fork cover

- Clutch actuator assembly

- Extension connector

- Motor 1 (Odd)

- Motor 2 (Even)

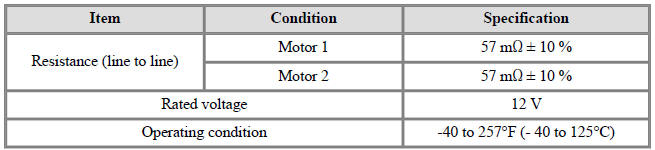

Specifications

Description

The clutch actuator uses signals from the Transmission Control Module (TCM) to control the clutch.

Schematic Diagrams

Clutch Actuator Assembly Repair procedures

Removal

Clutch Actuator Assembly Repair procedures

- Remove the under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

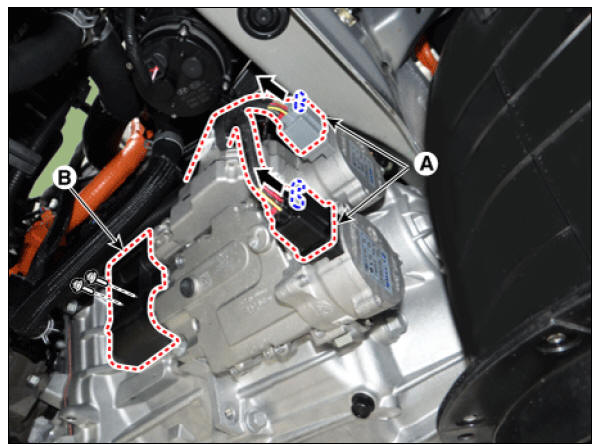

- Disconect the clutch actuator connector (A) and then remove the fork cover (B).

Tightening torque : 3.9 - 5.9 N*m (0.4 - 0.6 kgf*m, 2.9 - 4.3 lb*ft)

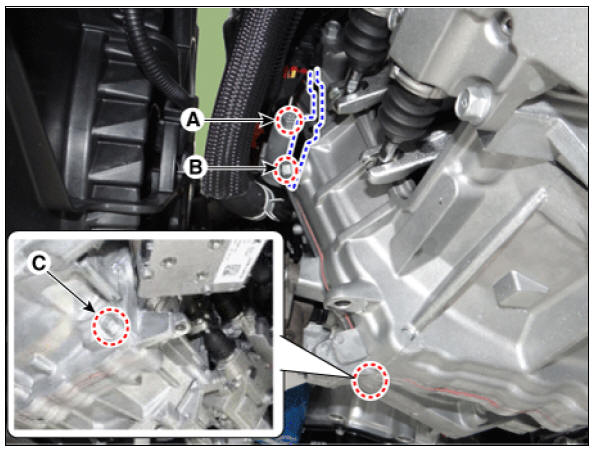

- Install the special service tool (09430-G2100).

(1) Loosen the bolts (A, B , C).

Tightening torque : (A, C) 42.2 - 53.9 N*m (4.3 - 5.5 kgf*m, 31.1 - 39.8 lb*ft) (B) 9.8 - 11.8 N*m (1.0 - 1.2 kgf*m, 7.2 - 8.7 lb*ft)

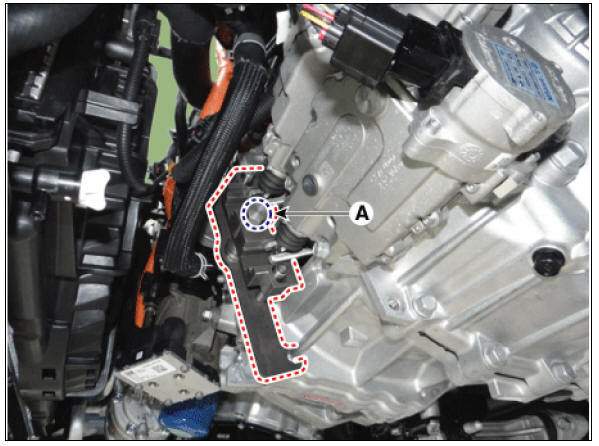

- Fix the clutch fork by rotating a bolt (A) after installing special service tool (09430-G2100).

- Remove the clutch actuator assembly (A) after loosening the bolts.

Tightening torque : 19.6 - 26.5 N*m (2.0 - 2.7 kgf*m, 14.5 - 19.5 lb*ft)

READ NEXT:

Clutch Actuator Motor

Clutch Actuator Motor

Remove the under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

Remove the front wheel guard (LH).

(Refer to Body - "Front Wheel Guard")

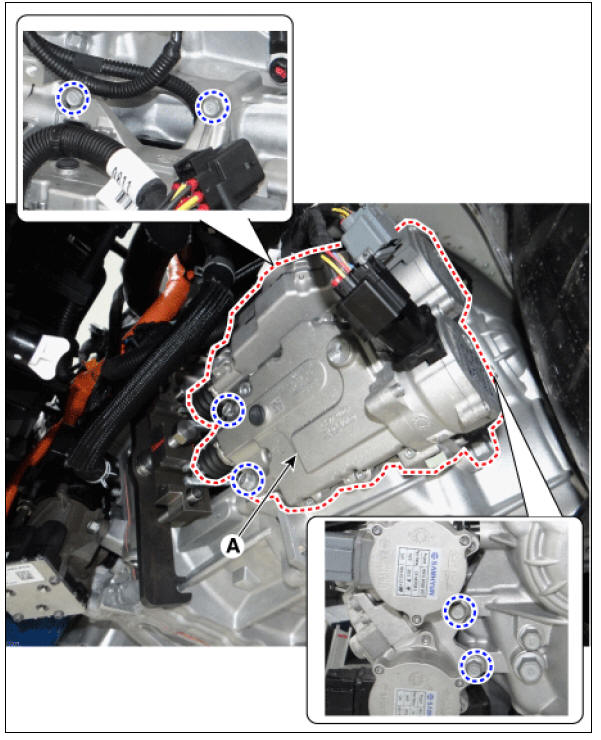

Disconect the clutch actuator connector (A).

Motor

Gear Actuator Assembly, Repair procedures

Gear Actuator Assembly, Repair procedures

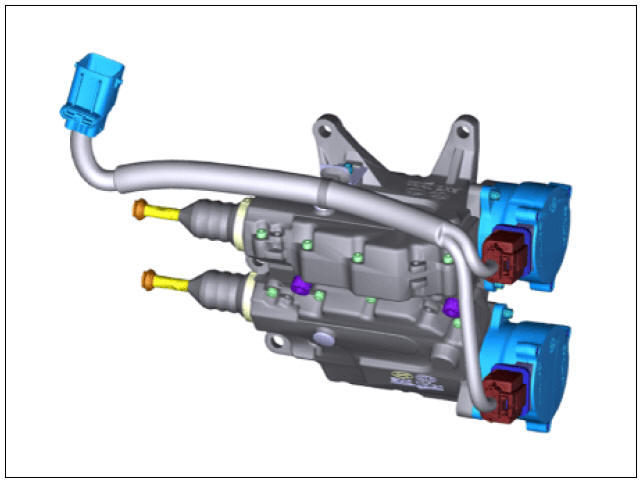

Component Location

Gear actuator assembly

Shift motor 2 (Even)

Shift motor 1 (Odd)

Select solenoid 2 (Even)

Select solenoid 1 (Odd)

Specification

Gear Actuator Assembly Description and operation

Description

SEE MORE:

Steering Column and Shaft Repair procedures

Steering Column and Shaft Repair procedures

Replacement

Warning

When a DTC related to MDPS motor occurs, check the connectors

and wiring. If no problem is found, replace the motor.

Be sure to check the last two digits of the constant in the

barcode of new MDPS motor before replaci

Injector

Injector

Specification

Description

The GDI injector is similar to a standard injector, but sprays fuel at a much

higher pressure directly

into the combustion chamber and has a swirl disc to get the fuel swirling as it

exits the nozzle. This

aids i

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us