KIA Niro: Piston, rings

- Clean piston.

(1) Using a gasket scraper, remove the carbon from the piston top.

(2) Using a groove cleaning tool or broken ring, clean the piston ring grooves.

(3) Using solvent and a brush, thoroughly clean the piston.

Warning

Do not use a wire brush.

- Check the piston-to-cylinder clearance by calculating the difference between the cylinder bore inner diameter and the piston outer diameter.

Piston-to-cylinder clearance : 0.025 - 0.045 mm (0.0010 - 0.0018 in.)

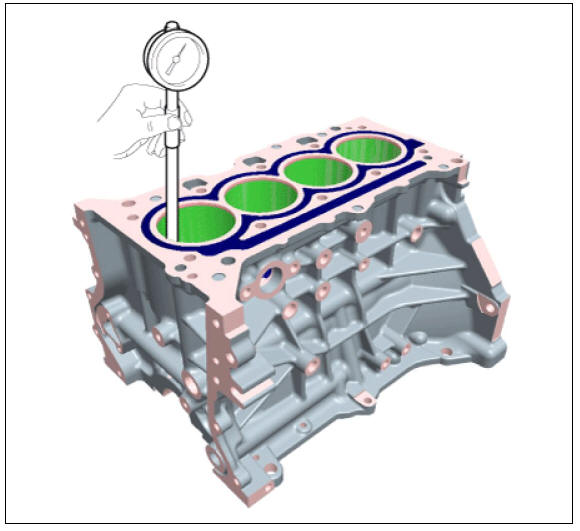

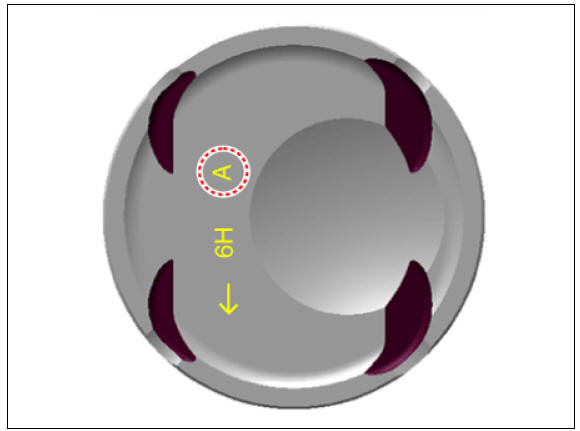

(1) Using a cylinder bore gauge, measure the cylinder bore diameter at position in the thrust and axial direction.

Cylinder bore diameter : 72.00 - 72.03 mm (2.8346 - 2.8358 in.)

Warning

Measure at 5mm (0.1969 in.) / 71.5mm (2.8150 in.) / 132.5mm (5.2165 in.) from the top of the cylinder block.

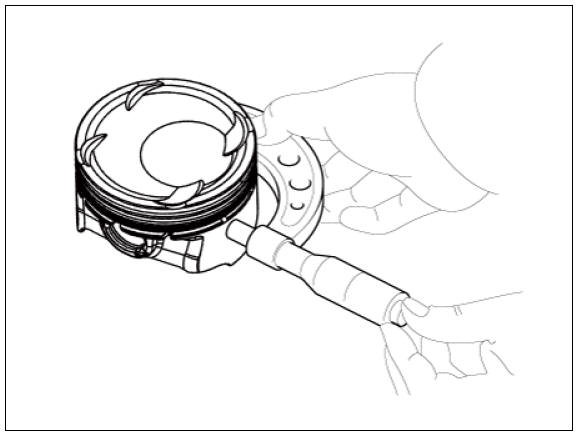

(2) Measure the piston outside diameter at 30 mm (1.1811 in) from top land of the piston.

Piston outside diameter : 71.965 - 71.995 mm (2.8333 - 2.8344 in.)

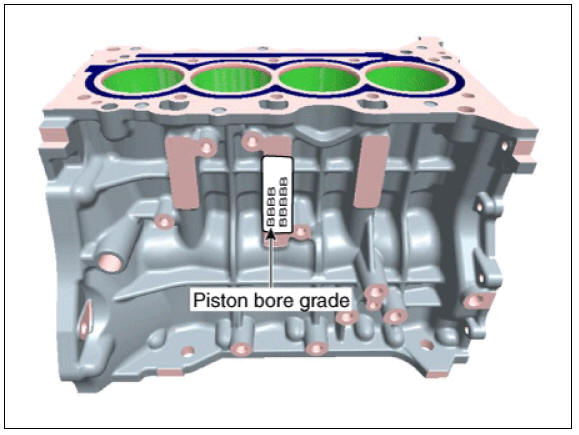

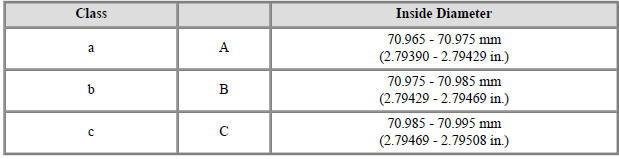

- Select the piston matching with cylinder bore class.

Piston-to-cylinder clearance : 0.025 - 0.045 mm (0.0010 - 0.0018 in.)

(1) Check the cylinder bore size code on the cylinder block side surface.

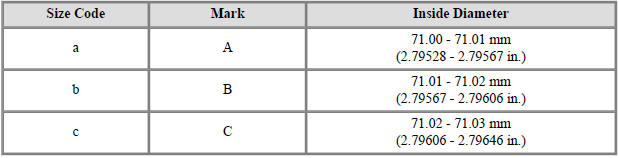

Cylinder Bore Inner Diameter

(2) Check the piston size mark on the piston top face.

Piston Outer Diameter

Piston Rings

- Inspect the piston ring side clearance.

Using a feeler gauge, measure the clearance between new piston ring and the wall of ring groove.

If the clearance is greater than maximum, replace the piston.

Piston ring side clearance : (Standard)

No.1 ring :

0.05 - 0.08 mm (0.0020 - 0.0031 in.) No.2 ring :

0.04 - 0.08 mm (0.0016 - 0.0031 in.) Oil ring :

0.050 - 0.125 mm (0.0020 - 0.0049 in.)

If the clearance is greater than maximum, replace the piston.

- Inspect piston ring end gap.

To measure the piston ring end gap, insert a piston ring into the cylinder bore. Position the ring at right angles to the cylinder wall by gently pressing it down with a piston. Measure the gap with a feeler gauge.

If the gap exceeds the service limit, replace the piston rings. If the gap is too large, recheck the cylinder bore inner diameter. If the bore is over the service limit, the cylinder block must be replaced.

Piston ring end gap :

(Standard)

No.1 ring: 0.13 - 0.18 mm (0.0051 - 0.0071 in.) No.2 ring: 0.25 - 0.40 mm (0.0098 - 0.0157 in.) Oil ring : 0.10 - 0.40 mm (0.0039 - 0.0157 in.)

READ NEXT:

Piston Pins

Piston Pins

Measure the diameter of the piston pin.

Piston pin diameter :

17.997 - 18.000 mm (0.70854 - 0.70866 in.)

Measure the piston pin-to-piston clearance.

Piston pin-to-piston clearance :

0.005 - 0.012 mm (0.00020 - 0.00047 in.)

Chec

Crankshaft Repair procedures

Crankshaft Repair procedures

Disassembly

Warning

Be sure to read and follow the "General Safety Information and

Caution" before doing any work related with

the high voltage system. Failure to follow the safety instructions may

result in serious electrical injuries.

SEE MORE:

Hood lower latch assembly

Hood lower latch assembly

Hood lower latch assembly

Replacement

Remove the front bumper cover.

(Refer to Front Bumper - "Front Bumper Cover")

Disconnect the hood lower latch connector (A).

Remove the engine clutch reservoir (A) after loos

Owner maintenance schedule

Owner maintenance schedule

When you stop for charging

Check the coolant level in the coolant

reservoir.

Check the windshield washer fluid

level.

Look for low or underinflated tires.

WARNING

Be careful when checking your coolant

level when the motor compartment

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us