KIA Niro: Alignment Repair procedures

Front wheel alignment

Warning

When using a commercially available computerized wheel alignment equipment to inspect the front wheel alignment, always position the vehicle on a level surface with the front wheels facing straight ahead.

Prior to inspection, make sure that the front suspension and steering system are in normal operating condition and that the tires are inflated to the specified pressure.

Toe

B - A > 0: Toe in (+)

B - A < 0: Toe out (-)

Toe adjustment

- Loosen the tie rod end lock nut.

- Remove the bellows clip to prevent the bellows from being twisted.

- Adjust the toe by screwing or unscrewing the tie rod. Toe adjustment should be made by turning the right and left tie rods by the same amount.

Toe-in

Total : 0.1º +- 0.2º

Individual : 0.05º +- 0.1º

- When completing the toe adjustment, install the bellows clip and tighten the tie rod end lock nut to specified torque.

Tightening torque: 49.0 - 53.9 N*m (5.0 - 5.5 kgf*m, 36.2 - 39.8 lb*ft)

- Perform the Steering Angle Sensor calibration.

- MDPS : (Refer to Steering System - "Electric Power Steering")

Camber and Caster

Camber and Caster are pre-set at the factory, so they do not need to be adjusted. If the camber and caster are not within the standard value, replace or repair the damaged parts and then inspect again.

Camber angle : -0.4º+-0.5º

Caster angle : 4.4º+-0.5º

Rear wheel alignment

Warning

When using a commercially available computerized wheel alignment equipment to inspect the rear wheel alignment, always position the vehicle on a level surface.

Prior to inspection, make sure that the rear suspension system is in normal operating condition and that the tires are inflated to the specified pressure.

Toe

B - A > 0: Toe in (+)

B - A < 0: Toe out (-)

Toe adjustment

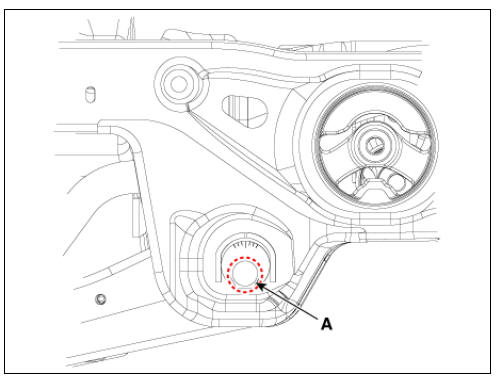

- Loosen the nut holding the assist arm cam bolt (A).

- Adjust rear toe by turning the rear assist arm cam bolt (A) clockwise or counter clockwise. Toe adjustment should be made by turning the right and left cam bolt by the same amount.

Toe-in

Total : 0.14º+-0.2º

Individual : 0.07º+-0.1º

- When completing the toe adjustment, tighten the nut to specified torque.

Tightening torque: 107.9 - 117.7 N*m (11.0 - 12.0 kgf*m, 79.6 - 86.8 lb*ft)

Camber

- Loosen the nut holding the lower arm cam bolt (A).

- Adjust rear camber by turning the rear lower arm cam bolt (A) clockwise or counterclockwise. Camber adjustment should be made by turning the right and left cam bolt by the same amount.

Camber : -1.2º+-0.5º

One scale turn : About 0.2º

Cam bolt (LH) : Clockwise camber (-)

Cam bolt (RH) : Clockwise camber (+)

- When completing the rear camber adjustment, tighten the nut to specified torque.

Tightening torque : 107.9 - 117.7 N*m (11.0 - 12.0 kgf*m, 79.6 - 86.8 lb*ft)

READ NEXT:

Tire Pressure Monitoring System

Tire Pressure Monitoring System

Tire Pressure Monitoring System / Components And Components Location

BCM (TPMS)

TPMS Sensor (FL)

TPMS Sensor (RL)

TPMS Sensor (RR)

TPMS Sensor (FR)

Description

TREAD Lamp

Tire Under Inflation / Leak Warning.

Turn on c

Troubleshooting - Tire Pressure Monitoring System

Troubleshooting - Tire Pressure Monitoring System

TPMS Inspection method

Inspection

Warning

Find the inspection number by referring to the table above.

The following content is irrelevant of the inspection procedure.

Warning lamp types

Stays on without blinking : Low pressure tir

TPMS Sensor Repair procedures

TPMS Sensor Repair procedures

Removal

Remove the valve core and deflate the tire.

Remove the side of the tire bead area from the wheel using tire changing

machine .

Warning

The tire bead should be broken approx. 90º from the valve side

of the wheel. The

SEE MORE:

High Voltage System

High Voltage System

Vehicle components

12V auxiliary battery

The 12V auxiliary battery is located in the right side of the luggage room,

and powers all of the vehicle's standard electronics like

radio, air conditioner, etc. Also, it powers the HPCU (Hybrid

Heated steering wheel

Heated steering wheel

Operation

Press the button to turn the heated

steering wheel ON or OFF.

The heated steering wheel reverts to

the OFF position whenever the vehicle

is restarted.

Operating condition(s) (Kia Niro EV)

The vehicle should be i

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us