KIA Niro: Engine Clutch Actuator

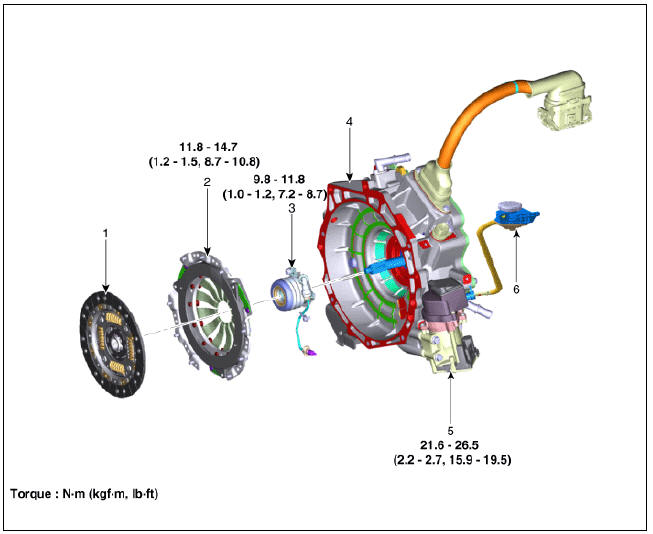

Components

- Clutch disc

- Clutch cover

- Concentric slave cylinder

- Hybrid motor assembly

- Engine clutch actuator

- Reservoir

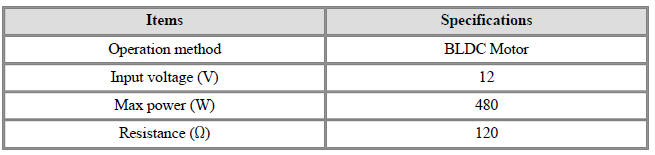

Specifications

Schematic Diagrams

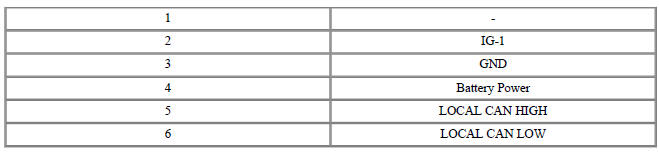

Harness Connector

Engine Clutch Actuator Repair procedures

Removal

Warning

Initialization and air bleeding procedure by using KDS can not be performed if the high voltage battery SOC is charged lower than 35%.

- Additional function which related to engine clutch can not be

operated if high voltage battery SOC is charged too low(lower

than 10%) or too high(higher than 90%), because of system limitation.

(Additional function which related to engine clutch : learning engine clutch/motor resolver, removing air in engine clutch oil pressure line, stabilizing engine clutch oil pressure line, stabilizing engine clutch hardware delivery torque, lerning engine clutch inspection of a vehicle and initialization of inspection information)

- Turn the ignition switch OFF and disconnect the battery (-) terminal.

- Remove the under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

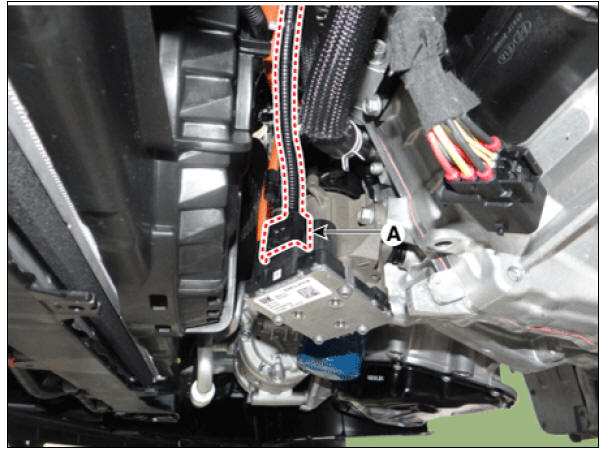

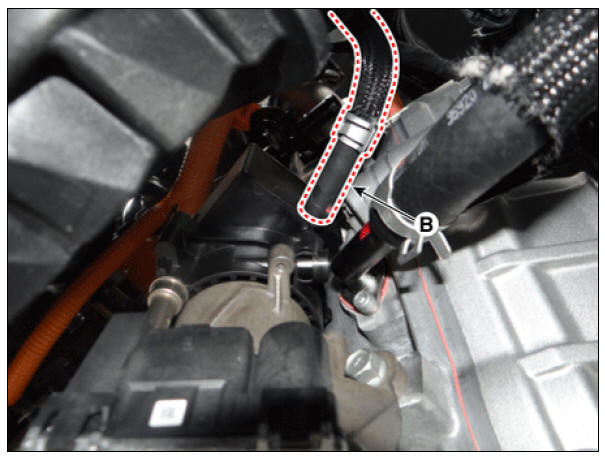

- Disconnect the engine clutch actuator connector (A) and hose (B).

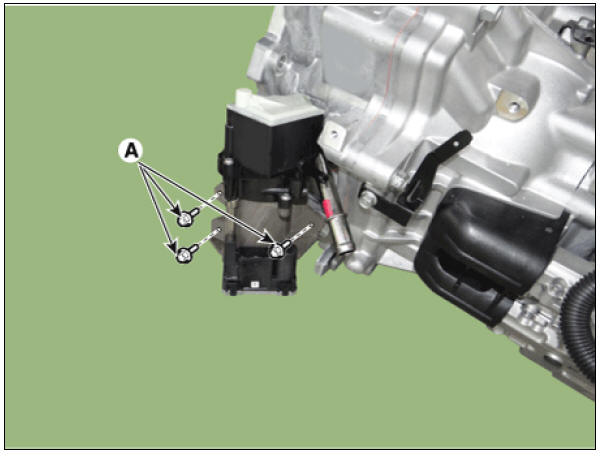

- Loosen the engine clutch actuator bolts (A) and then remove the engine clutch actuator.

Tightening torque : 21.6 - 26.5 N.m (2.2 - 2.7 kgf.m, 15.9 - 19.5 lb-ft)

Warning

Make sure that the hydraulic fluid or foreign substance does not enter the connector assembly of the actuator.

Installation

- Install in the reverse order of removal.

Warning

Before installing the engine clutch actuator, check the assembled state of the O-rings (A).

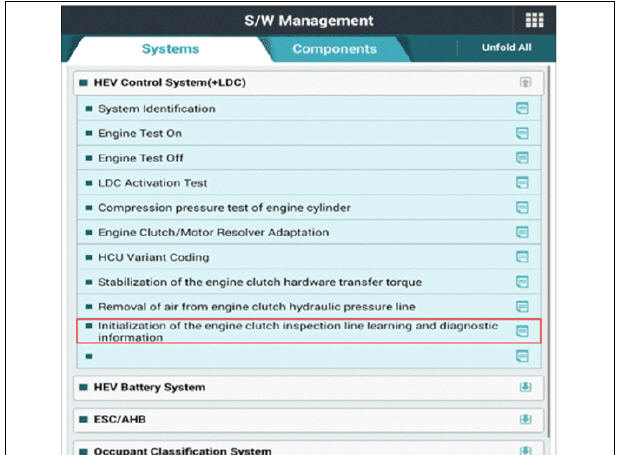

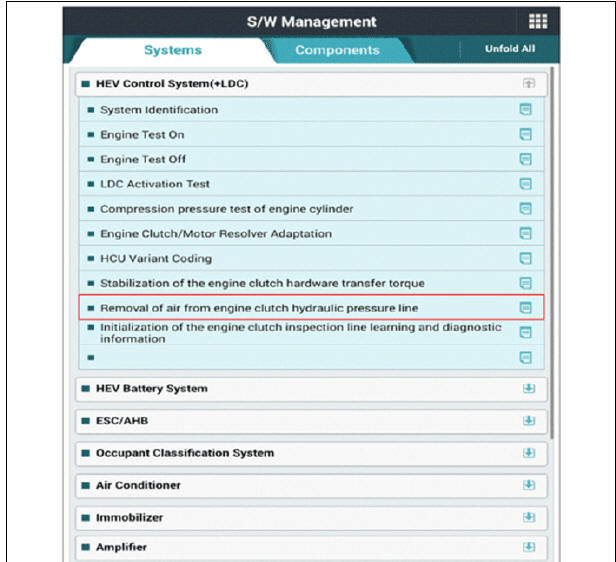

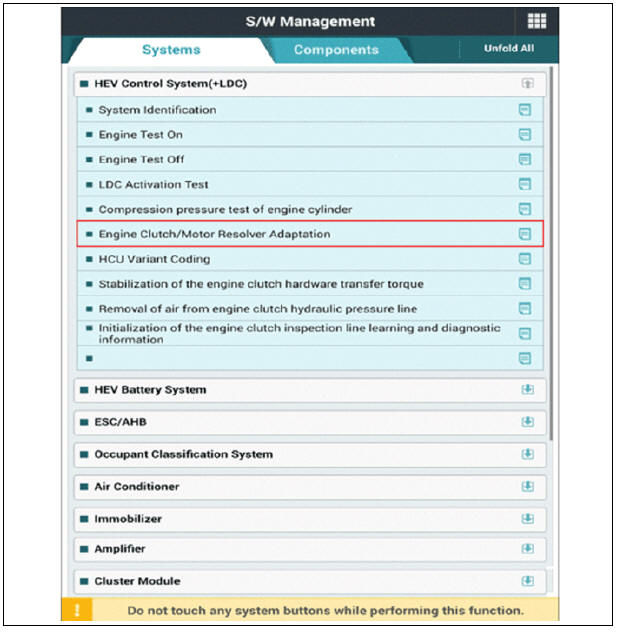

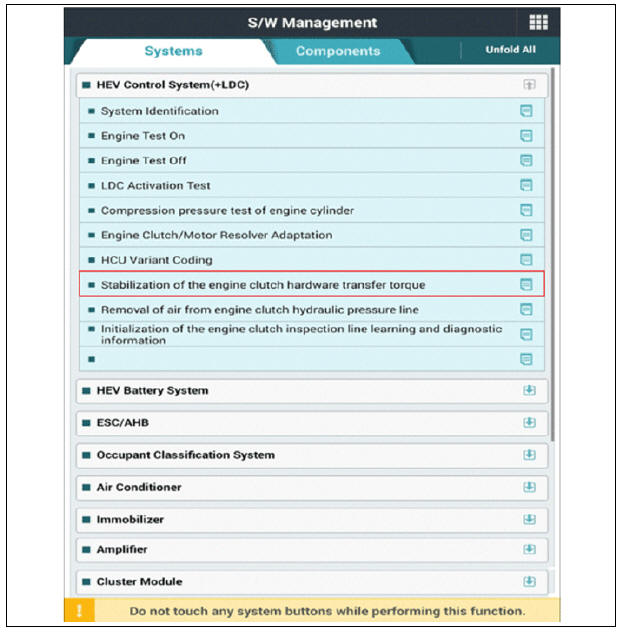

- After replacing the engine clutch actuator, operate the followings in order using KDS.

(1) Perform initialization of the engine clutch inspection line learning and diagnostic information.

(2) Bleed the air from engine clutch hydraulic pressure line

Warning

Be sure to bleed air from the engine clutch hydraulic pressure line at outside temperature between 0 - 40ºC (32 - 104ºF). If not, the air bleeding would be not done well.

Warning

Refil the hydraulic fluid to MAX-MIN level, if the fluid is lower than MIN level while performing the air bleeding.

(3) Perform engine clutch/motor resolver adaptation.

(4) Perform stabilization of the engine clutch hardware transfer torque.

READ NEXT:

Concentric Slave Cylinder Assembly Repair procedures

Concentric Slave Cylinder Assembly Repair procedures

Removal

Remove the hybrid motor assembly.

(Refer to Hybrid Motor System - "Hybrid Motor Assembly")

Remove the engine clutch actuator.

(Refer to Engine Clutch System - "Engine Clutch Actuator")

Remove the adapter (A

Clutch Cover And Disc Repair procedures

Clutch Cover And Disc Repair procedures

Removal

Remove the hybrid motor assembly.

(Refer to Hybrid Motor System - "Hybrid Motor Assembly")

Remove the clutch cover assembly and clutch disc after loosening the

bolts.

Warning

Be careful not to be bent or twist b

Reservoir Repair procedures

Reservoir Repair procedures

Removal

Turn the ignition switch OFF and disconnect the battery (-) terminal.

Drain the hydraulic oil from the reservoir using a syringe.

Loosen the reservoir hose (A) and bolts (B) and then remove the

reservoir.

Tightening torque :

3.

SEE MORE:

Resolver Sensor Repair procedures | Motor Temperature Sensor Repair procedures

Resolver Sensor Repair procedures | Motor Temperature Sensor Repair procedures

Inspection

Hybrid Drive Motor

Inspect the resolver sensor resistance.

If the resolver sensor needs to be replaced, replace the hybrid drive motor assembly.

(Refer to Hybrid Motor Assembly - "Hybrid Drive M

AC charger

AC charger

AC Charger

AC charger cable

You can charge your vehicle by plugging

into a public charger at a charging station.

How to connect AC charger

Depress the brake pedal and apply

the parking brake.

Turn OFF all switches, move th

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us