KIA Niro: Engine Mechanical System / Troubleshooting

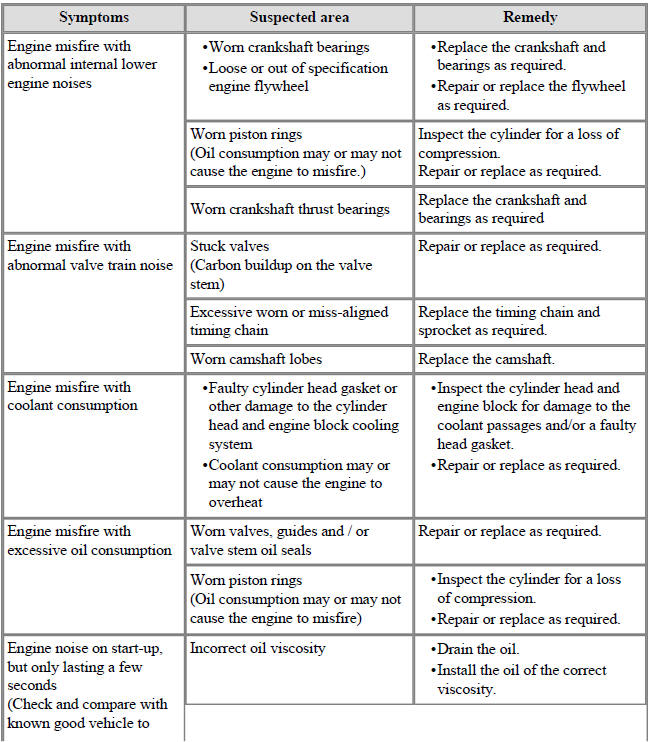

Symptoms :

Engine misfire with abnormal internal lower engine noises

Suspected area → Remedy

-

Worn crankshaft bearings → Replace the crankshaft and bearings as required.

-

Loose or out of specification engine flywheel → Repair or replace the flywheel

as required.

Worn piston rings

(Oil consumption may or may not cause the engine to misfire.) → Inspect the cylinder for a loss of

compression.

Repair or replace as required.

Worn crankshaft thrust bearings→ Replace the crankshaft and

bearings as required

Symptoms :

Engine misfire with abnormal valve train noise

Suspected area → Remedy

Stuck valves

(Carbon buildup on the valve stem) → Repair or replace as required.

Excessive worn or miss-aligned timing chain → Replace the timing chain and sprocket as required.

Worn camshaft lobes →Replace the camshaft.

Symptoms :

Engine misfire with coolant consumption

Suspected area → Remedy

-

Faulty cylinder head gasket or other damage to the cylinder head and engine block cooling system → Inspect the cylinder head and engine block for damage to the coolant passages and/or a faulty head gasket.

-

Coolant consumption may or may not cause the engine to overheat → Repair or replace as required.

Symptoms :

Engine misfire with excessive oil consumption

Suspected area → Remedy

Worn valves, guides and / or valve stem oil seals → Repair or replace as required.

Worn piston rings

(Oil consumption may or may not cause the engine to misfire) →

-

Inspect the cylinder for a loss

of compression. -

Repair or replace as required.

Symptoms :

Engine noise on start-up, but only lasting a few

seconds

(Check and compare with

known good vehicle to determine normal condition.)

Suspected area → Remedy

Incorrect oil viscosity →

-

Drain the oil.

-

Install the oil of the correct viscosity.

Worn crankshaft thrust bearing →

-

Inspect the thrust bearing and crankshaft.

-

Repair or replace as required.

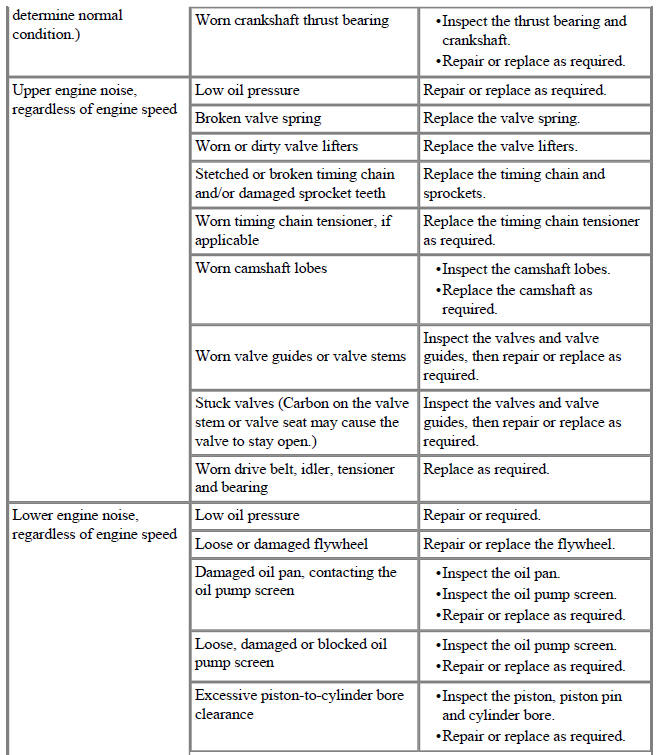

Symptoms :

Upper engine noise, regardless of engine speed

Suspected area → Remedy

Low oil pressure →

Repair or replace as required.

Broken valve spring → Replace the valve spring.

Worn or dirty valve lifters → Replace the valve lifters.

Stetched or broken timing chain and/or damaged sprocket teeth → Replace the timing chain and

sprockets.

Worn timing chain tensioner, if applicable →Replace the timing chain tensioner as required.

Worn camshaft lobes →

-

Inspect the camshaft lobes.

-

Replace the camshaft as required.

Worn valve guides or valve stems → Inspect the valves and valve

guides, then repair or replace as required.

Stuck valves (Carbon on the valve stem or valve seat may cause the valve to stay open.) → Inspect the valves and valve

guides, then repair or replace as required.

Worn drive belt, idler, tensioner and bearing → Replace as required.

Symptoms :

Lower engine noise, regardless of engine speed

Suspected area → Remedy

Low oil pressure → Repair or required.

Loose or damaged flywheel → Repair or replace the flywheel.

Damaged oil pan, contacting the oil pump screen →

-

Inspect the oil pan.

-

Inspect the oil pump screen.

-

Repair or replace as required.

Loose, damaged or blocked oil pump screen →

-

Inspect the oil pump screen.

-

Repair or replace as required.

Excessive piston-to-cylinder bore clearance →

-

Inspect the piston, piston pin and cylinder bore.

-

Repair or replace as required.

Excessive piston pin-to-piston clearance →

-

Inspect the piston, piston pin and the connecting rod.

-

Repair or replace as required.

Excessive connecting rod bearing clearance →

Inspect the following components

and repair or replace as required.

-

The connecting rod bearings.

-

The connecting rods.

-

The crankshaft pin journals.

Excessive crankshaft bearing clearance → Inspect the following components, and repair or replace as required.

-

The crankshaft bearings.

-

The crankshaft main journals.

-

The cylinder block

Incorrect piston, piston pin and connecting rod installation →

-

Verify the piston pins and connecting rods are installed correctly.

-

Repair as required.

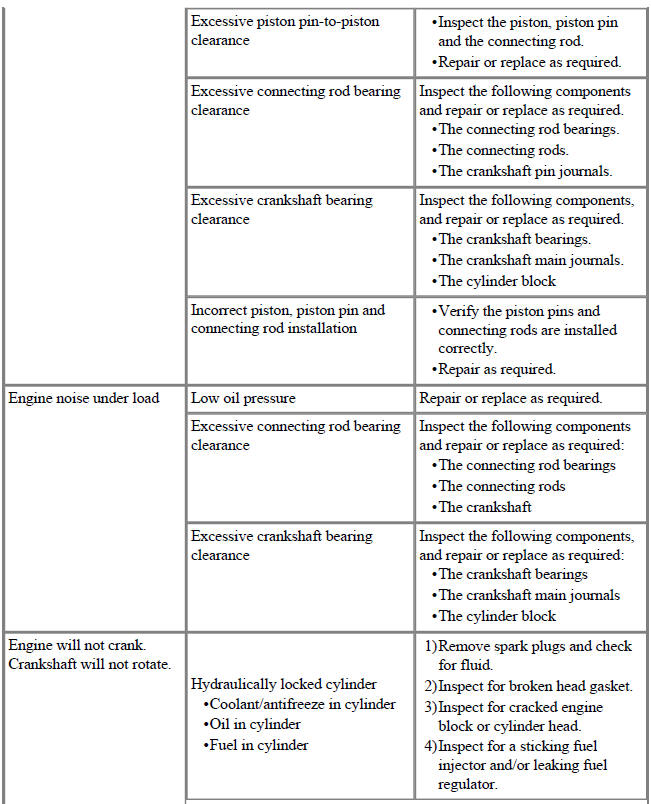

Symptoms :

Engine noise under load

Suspected area → Remedy

Low oil pressure → Repair or replace as required.

Excessive connecting rod bearing clearance → Inspect the following components and repair or replace as required:

-

The connecting rod bearings

-

The connecting rods

-

The crankshaft

Excessive crankshaft bearing clearance → Inspect the following components, and repair or replace as required:

-

The crankshaft bearings

-

The crankshaft main journals

-

The cylinder block

Symptoms :

Engine will not crank.

Crankshaft will not rotate.

Suspected area → Remedy

Hydraulically locked cylinder

-

Coolant/antifreeze in cylinder

-

Oil in cylinder

-

Fuel in cylinder → 1) Remove spark plugs and check

for fluid.2) Inspect for broken head gasket.

3) Inspect for cracked engine block or cylinder head.

4) Inspect for a sticking fuel injector and/or leaking fuel regulator.

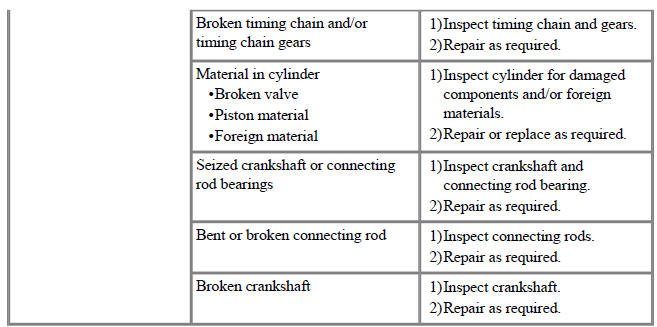

Broken timing chain and/or timing chain gears →1) Inspect timing chain and gears.

2) Repair as required.

Material in cylinder

-

Broken valve

-

Piston material

-

Foreign material → 1) Inspect cylinder for damaged components and/or foreign materials.

2) Repair or replace as required.

Seized crankshaft or connecting rod bearings →1) Inspect crankshaft and connecting rod bearing.

2) Repair as required.

Bent or broken connecting rod → 1) Inspect connecting rods.

2) Repair as required.

Broken crankshaft → 1) Inspect crankshaft.

2) Repair as required.

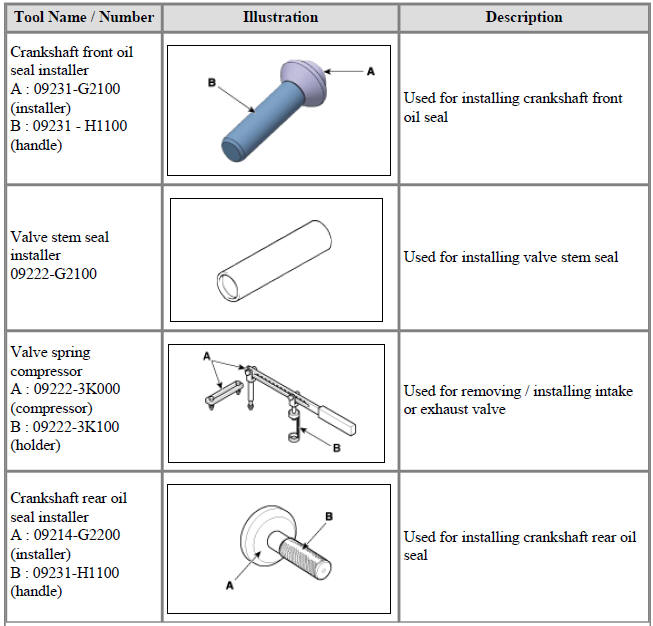

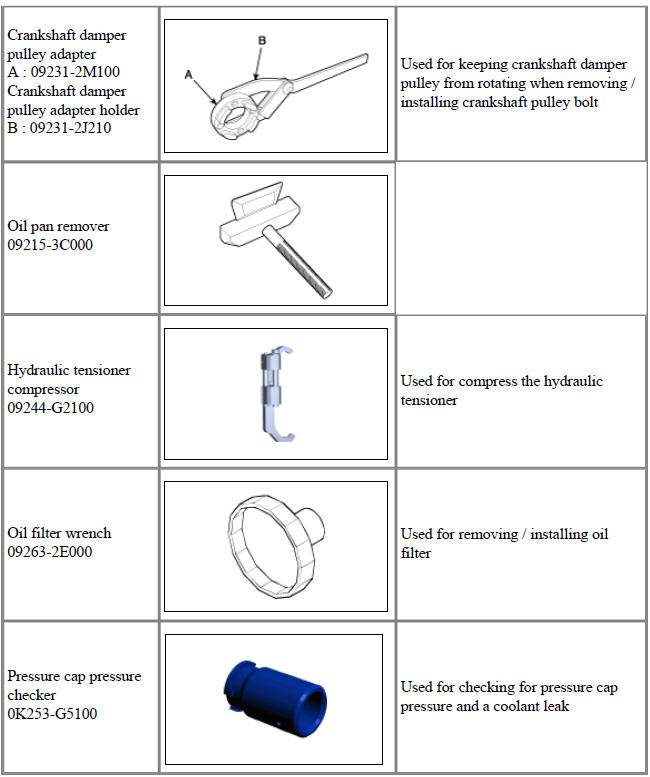

Special Service Tools

READ NEXT:

Cooling System

Cooling System

Components

Reservoir tank

Reservoir hose & pipe

Radiator

Radiator upper hose

Radiator lower hose

Radiator upper mounting bracket (RH)

Radiator upper mounting bracket (LH)

Radiator lower mounting insulator (RH)

Radiator low

Coolant Repair procedures

Coolant Repair procedures

Warning

Never remove the radiator cap when the engine is hot. Serious

scalding could be caused by hot fluid under

high pressure escaping from the radiator.

Warning

When pouring engine coolant, shut the relay box lid and be careful

not to spil

Cooling Fan Repair procedures | Cooling Fan Assembly

Cooling Fan Repair procedures | Cooling Fan Assembly

Cooling Fan Components and components location

Components

Cooling fan

Cooling fan motor

Cooling fan shroud

Air dam

Cooling fan controller (PWM)

Description

Controls the cooling fan motor voltage depending on the duty

SEE MORE:

Fuel Pressure Test (Low pressuresystem)

Fuel Pressure Test (Low pressuresystem)

Release the residual pressure in fuel line.

(Refer to the Fuel Delivery System - Inspection - "Release Residual Pressure

in Fuel Line").

Warning

When removing the fuel pump fuse, a Diagnostic Trouble Code (DTC)

may occur. De

Passenger's front air bag ON/OFF settings (Kia NIRO Hybrid)

Passenger's front air bag ON/OFF settings (Kia NIRO Hybrid)

You can deactivate the passenger's front

air bag from the User Settings Mode on

the LCD display if a child restraint is

installed on the front passenger's seat or

if the front passenger's seat is unoccupied

by a person. If your vehic

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us