KIA Niro: Exhaust Emission Control System

Description

Exhaust emissions (CO, HC, NOx) are controlled by a combination of engine

modifications and the

addition of special control components.

Modifications to the combustion chamber, intake manifold, camshaft and ignition

system form the

basic control system.

These items have been integrated into a highly effective system which controls

exhaust emissions

while maintaining good drivability and fuel economy.

Description

The catalytic converter of the gasoline engine is a three way catalyst. It oxidizes carbon monoxide and hydrocarbons (HC), and separates oxygen from the oxides of nitrogen (NOx).

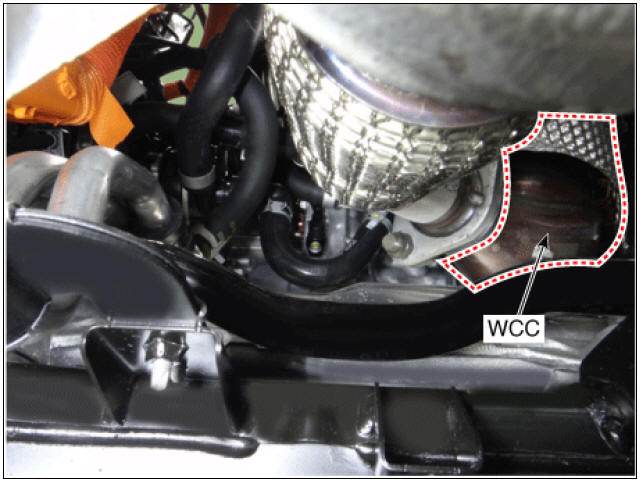

Catalytic Converter (WCC)

CVVT (Continuous Variable Valve Timing) System Description and operation

Description

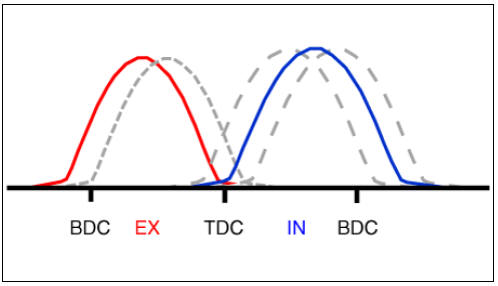

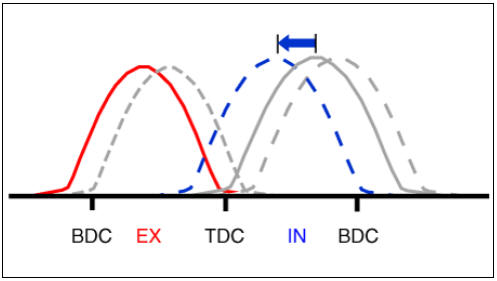

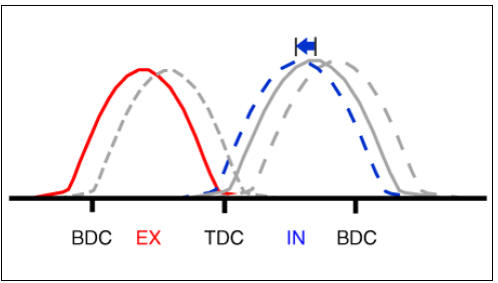

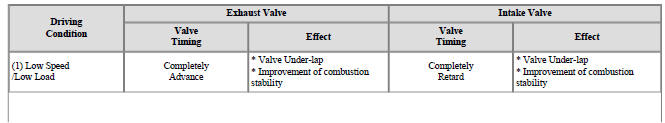

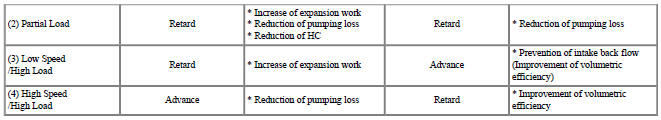

Continuous Variable Valve Timing (CVVT) system advances or retards the valve timing of the intake and exhaust valve in accordance with the ECM control signal which is calculated by the engine speed and load.

By controlling CVVT, the valve overlap or underlap occurs, which makes better fuel economy, reduces exhaust gases (NOx, HC) and improves engine performance by reducing pumping loss, giving internal EGR effect, improving combustion stability and volumetric efficiency, and increasing expansion work.

This system consists of

- the CVVT Oil Control Valve (OCV) which supplies the engine oil to the

cam phaser or takes out the engine oil from the cam phaser in accordance

with the ECM

PWM (Pulse Width Modulation) control signal, - the CVVT Oil Temperature Sensor (OTS) which measures the engine oil temperature,

- Cam Phaser : Changes the cam phase by using the hydraulic force of the engine oil.

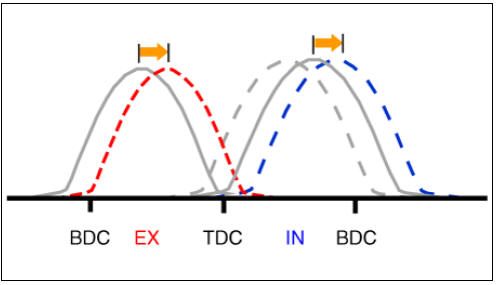

The engine oil which is supplied from the CVVT oil control valve changes the cam phase in the direction (Intake Advance/Exhaust Retard) or opposite direction (Intake Retard/Exhaust Advance) of the engine rotation by rotating the rotor connected with the camshaft inside the cam phaser.

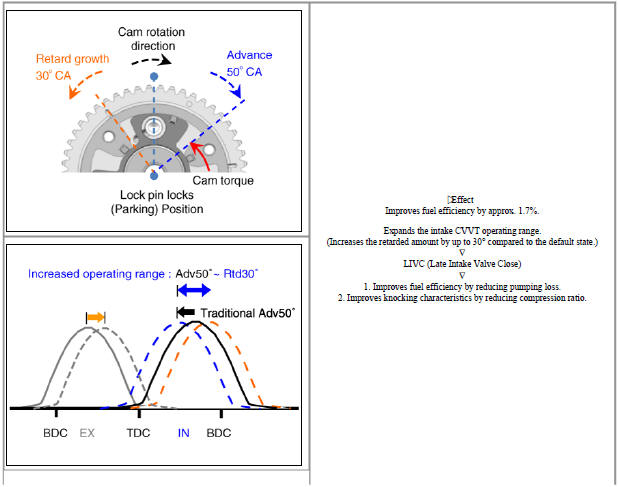

Intermediate Lock CVVT

It increases the retarded amount compared to the default state to expand the operating range of the variable valve timing system.

The cam phase is fixed mechanically so that it is locked at the middle

position.

Operation

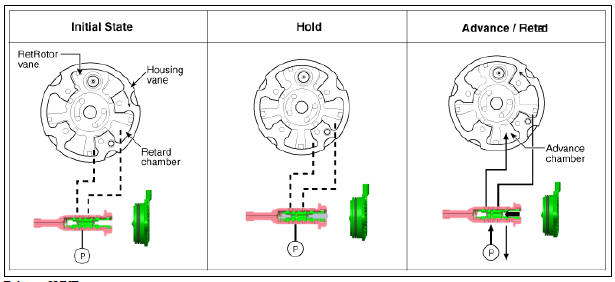

Principle

The CVVT has the mechanism of rotating the rotor vane with hydraulic force

generated by the engine oil supplied to the advance or retard chamber in

accordance with

the CVVT oil control valve control.

Warning

- The variable force solenoid (VFS) changes its force depending on the PWM duty to control the stroke of the OCV.

- It also controls the lock, unlock, advanced, retarded, and holding functions.

- Intake CVVT

- Exhaust CVVT

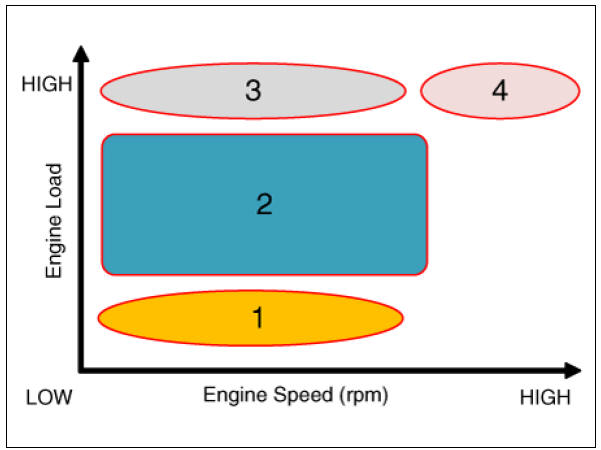

CVVT System Mode

Low Speed / Low Load

Low Speed / Low Load

Partial Load

Partial Load

Low Speed / High Load

Low Speed / High Load

High Speed / High Load

High Speed / High Load

Circuit Diagram

Diagram Variable Force Solenoind (VFS) (Bank 1 / Intake)

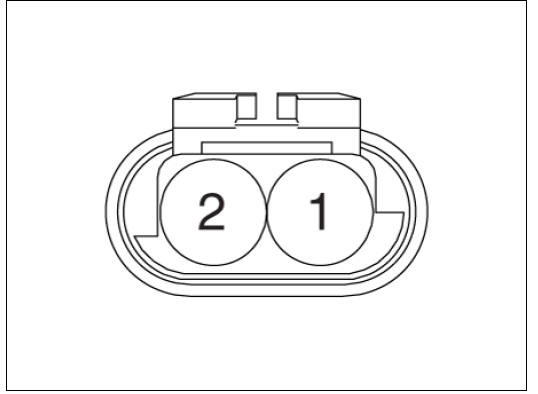

Harness Connector

CVVT Oil Control Valve (OCV) (Bank 1 / Exhaust)

Harness Connector

Inspection

CVVT Oil Control Valve (OCV)

Refer to Engine Control / Fuel System - "CVVT Oil Control Valve (OCV)"

Removal

Variable Force Solenoind (VFS)

Refer to Engine Control / Fuel System - "Variable Force Solenoind (VFS)"

CVVT Oil Control Valve (OCV)

Refer to Engine Control / Fuel System - "CVVT Oil Control Valve (OCV)"

Installation

Variable Force Solenoind (VFS)

Refer to Engine Control / Fuel System - "Variable Force Solenoind (VFS)"

CVVT Oil Control Valve (OCV)

Refer to Engine Control / Fuel System - "CVVT Oil Control Valve (OCV)"

READ NEXT:

The Gasoline Particulate Filter (GPF)

The Gasoline Particulate Filter (GPF)

Description

The Gasoline Particulate Filter (GPF) system prevents Particulate Matter (PM)

from being discharged to the atmosphere and

consists of a filter assembly, two Exhaust Gas Temperature Sensors (EGTS). The

filter is integrated in the cat

Engine Control / Fuel System

Engine Control / Fuel System

Specifications

Fuel Delivery System

Sensors

Manifold Absolute Pressure Sensor (MAPS)

Type: Piezo-resistive pressure sensor type

Specification

Intake Air Temperature Sensor (IATS)

Type: Thermistor type

Specification

Basic Troubleshooting

Basic Troubleshooting

Basic Troubleshooting Guide

Customer Problem Analysis Sheet

Basic Inspection Procedure

Measuring Condition of Electronic Parts' Resistance

The measured resistance at high temperature after vehicle

running may be high or low. So all

SEE MORE:

Emergency towing

Emergency towing

Front

Rear

Operation

Remove the hole cover by pressing

the lower part of the cover on the

bumper.

Install the towing hook by screwing it

clockwise into the hole until it is fully

secured.

After use, remove the towing hook

and

Charging the electric vehicle (Abrupt stop)

Charging the electric vehicle (Abrupt stop)

Action to be taken when charging

stops abruptly

When the high voltage battery does not

charge, check the followings:

Check the charging setting for the

vehicle. Refer to "EV settings" (e.g. When scheduled charging is

set, c

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us