KIA Niro: Front Washer Motor Repair procedures

Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual / Body Electrical System / Windshield Wiper/Washer / Front Washer Motor Repair procedures

Inspection

- With the washer motor connected to the reservoir tank, fill the reservoir tank with water.

Warning

Before filling the reservoir tank with water, check the filter for foreign material or contamination. if necessary, clean the filter.

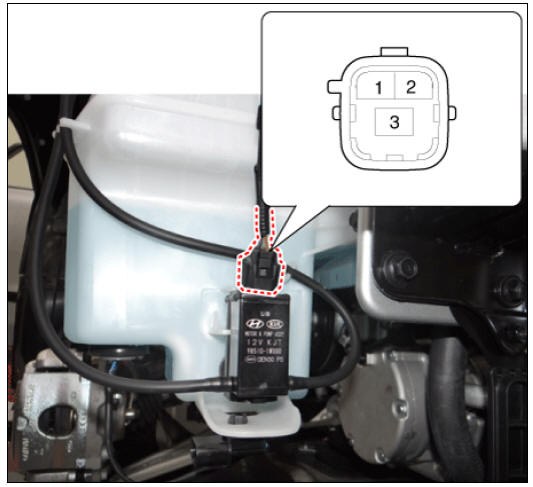

- Connect positive (+) battery cables to power terminal (Front : 1, Rear 3) and negative (-) battery cables to ground terminal 2 respectively.

- Check that the motor operates normally and the washer motor runs and water sprays from the front nozzles.

- If they are abnormal, replace the washer motor.

Washer Fluid Level Sensor Switch

- Drain the washer fluid less than 650 cc.

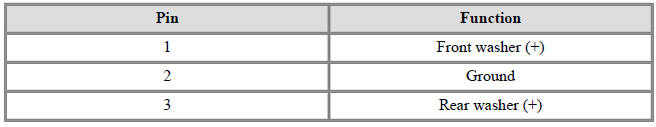

- Check for continuity between the No. 1 and No.2 terminal in each float

position.

There should be continuity when the float is down.

There should be no continuity when the float is up.

- If the continuity is not as specified, replace the washer fluid level switch

- If the continuity is not as specified, replace the washer fluid level switch.

Removal

Washer Motor

- Remove the engine room under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

- Drain the washer fluid to less than 650 cc.

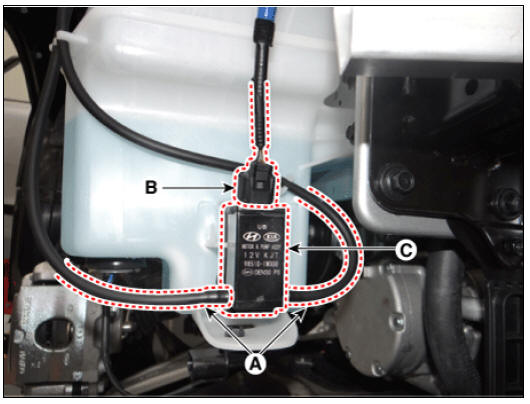

- Disconnect the washer hose (A) and washer motor connector (B).

- Remove the front washer motor (C).

Washer Fluid Level Sensor

- Remove the engine room under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

- Drain the washer fluid to less than 650 cc.

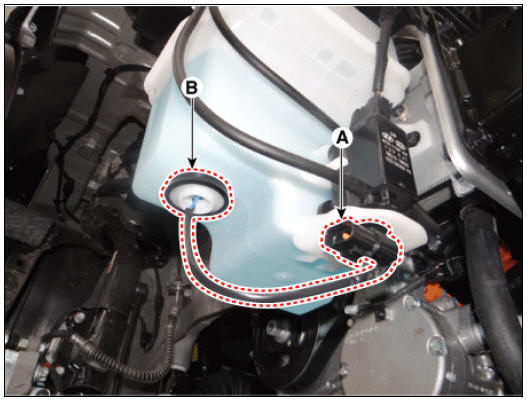

- Remove the washer fluid level sensor switch (B) after disconnecting the connector (A).

Reservoir

- Remove the engine room under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

- Remove the front wheel guard (RH).

(Refer to Body - "Front Wheel Guard")

- Drain the washer fluid to less than 650 cc.

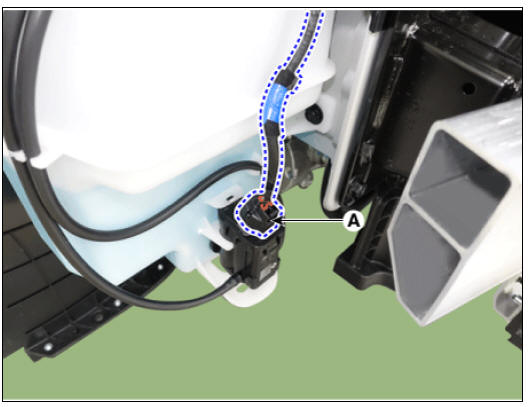

- Disconnect the washer motor connector (A).

- Remove the reservoir.

(1) Separate the washer hose.

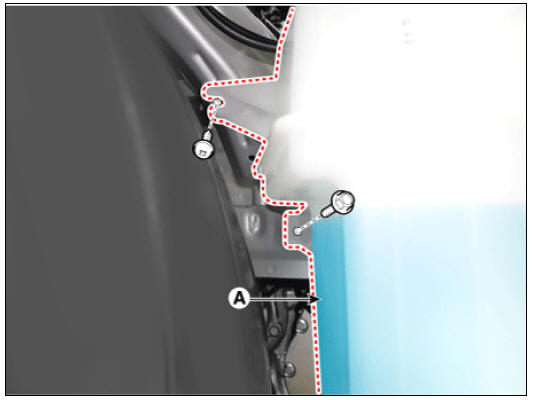

(2) Remove the reservoir by loosening the bolts and screw.

Installation

- Install in the reverse order of removal.

READ NEXT:

Rain Sensor Repair procedures

Rain Sensor Repair procedures

Inspection

Check point for rain sensor:

To properly adjust sensitivity if auto wiping operates sensitively or

insensitively.

To check if a connector of sensor is normally connected

To check if sensor and bracket are normal

Gel pad

Gel pad

Replacement

Remove the damaged silicone gel pad completely on the lens plate of rain

sensor.

Warning

The silicone gel must be fully detached from the rain sensor by

rubbing it off with the fingers

without any tool.

The surface

SEE MORE:

Tires and wheels

Tires and wheels

Tire care

For proper maintenance, safety, and

maximum fuel economy, you must

always maintain recommended tire

inflation pressures and stay within the

load limits and weight distribution recommended

for your vehicle.

Recommended cold tire infla

Fuel Filter Repair procedures

Fuel Filter Repair procedures

Removal

Remove the fuel pump.

(Refer to Fuel Delivery System - "Fuel Pump")

Disconnect the fuel pump motor connector (A) and fuel sender connector

(B).

Lift the fixing hook (A) by using a common driver, and then remov

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us