KIA Niro: Drive Belt / Idler Repair procedures

Drive Belt Repair procedures

Removal

- Remove the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

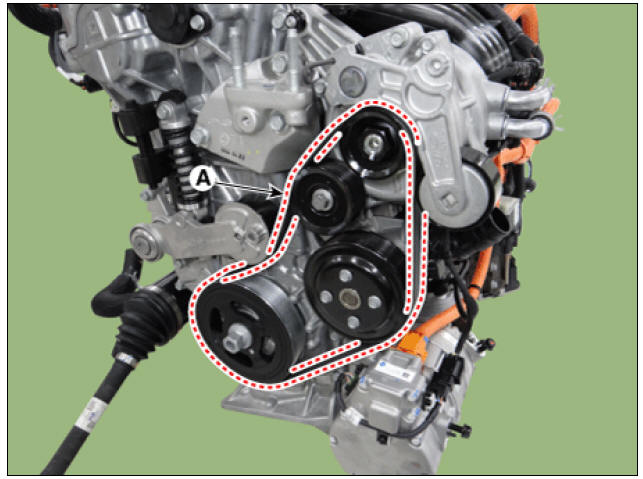

- Remove the drive belt.

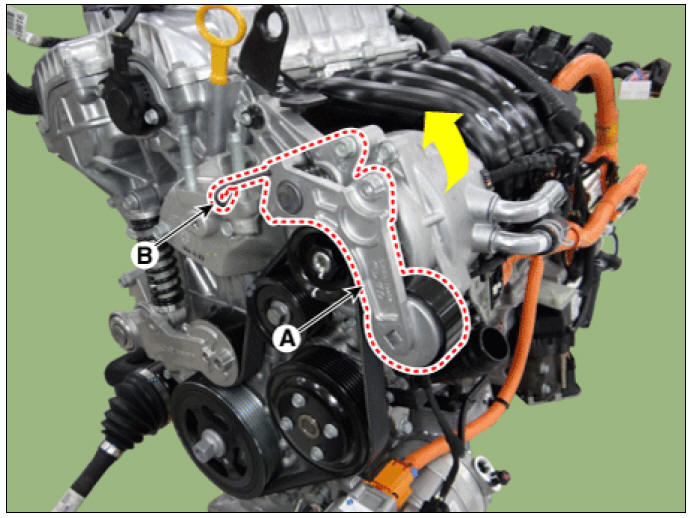

(1) Using the wrench, turning the mechanical tensioner (A) counterclockwise

and then insert a

stopper pin (B) into the hole.

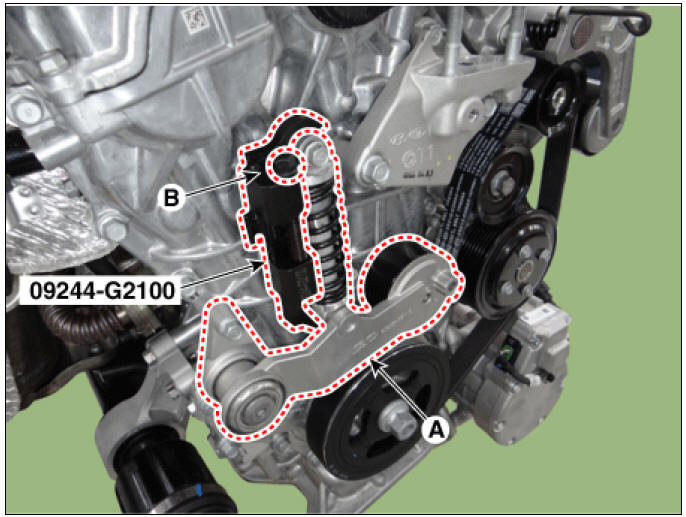

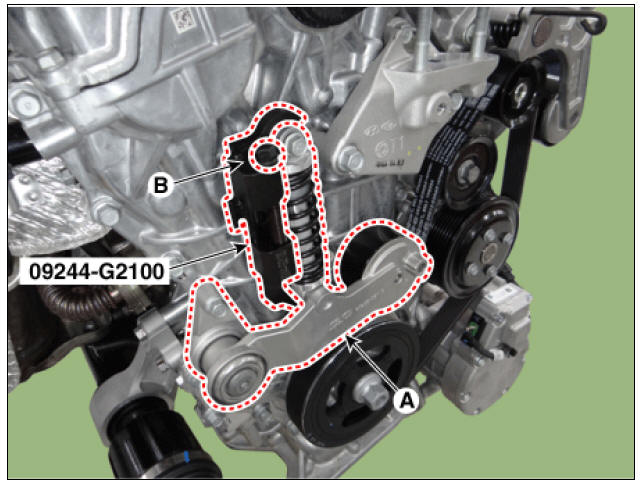

(2) Install the SST (09244 - G2100) to hydraulic tensioner (A) and then

compress the hydraulic

tensioner by tightening the adjusting bolt (B).

Warning

- To prevent damage the hydraulic tensioner, slowly must work by using the hand tool.

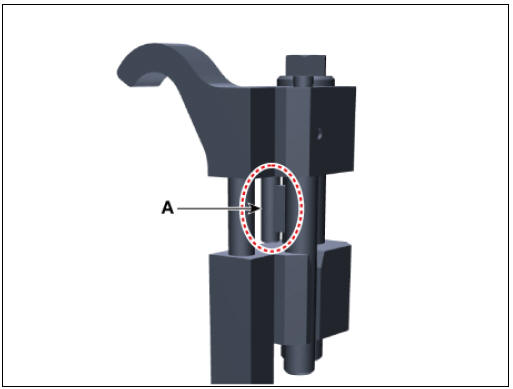

- Before using the SST (09244-G2100), check the safety pin (A) is

positioned well as

shown in the image below.

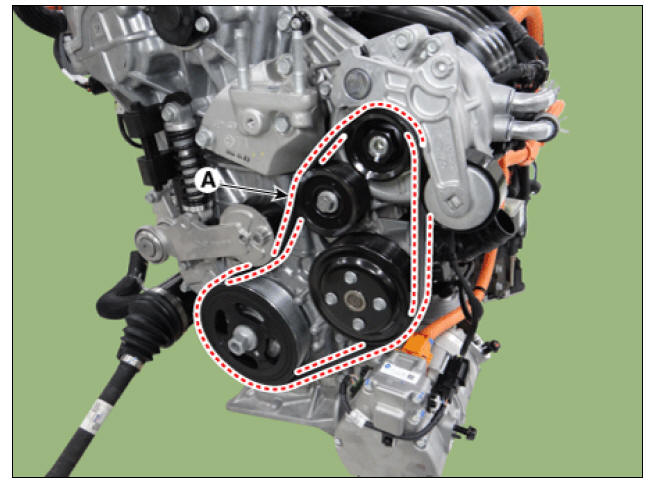

(3) Remove the drive belt (A).

Installation

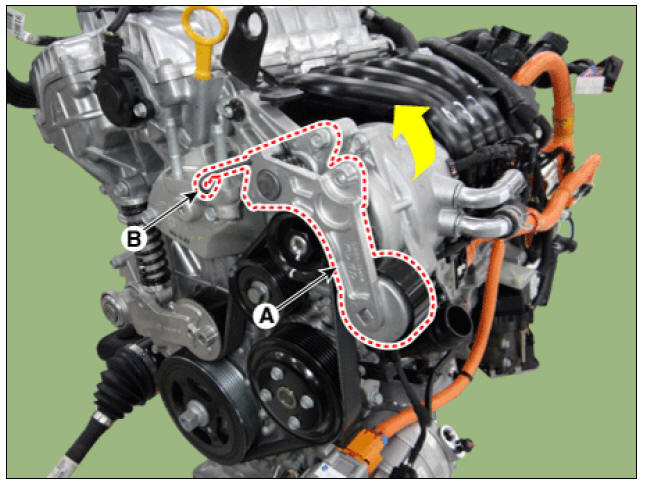

- Install the drive belt.

(1) Install the drive belt (A).

(2) Remove the SST (09244 - G2100) from the hydraulic tensioner (A) by

loosening the adjusting

bolt (B).

Warning

To prevent damage the hydraulic tensioner, slowly must work by using the hand tool.

(3) Using the wrench, slightly lift the mechanical tensioner (A) and then remove the stopper pin (B).

Slowly place the mechanical tensioner (A).

- Install the engine room under cover.

(Refer to Engine And Transaxle Assembly - "Engine Room Under Cover")

Inspection

Visually check the belt for excessive wear, frayed cords etc. If any defect has been found, replace the drive belt.

Warning

Cracks on the rib side of a belt are considered acceptable. If the

belt has chunks missing from the

ribs, it should be replaced.

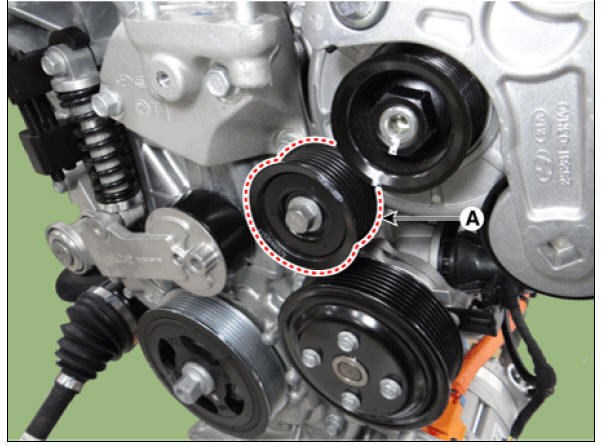

Idler Repair procedures

Removal and

Installation

- Remove the drive belt.

(Refer to Drive Belt System - "Drive Belt")

- Remove the idler (A).

Tightening torque : 39.2 - 49.0 N*m (4.0 - 5.0 kgf*m, 28.9 - 36.2 lb*ft)

- Install in the reverse order of removal

Inspection

Check the idler for excessive oil leakage, abnormal rotation or vibration. Replace if necessary.

READ NEXT:

Drive Belt Tensioner Repair procedures

Drive Belt Tensioner Repair procedures

Removal and

Installation

Remove the drive belt.

(Refer to Drive Belt System - "Drive Belt")

Remove the mechanical tensioner (A).

Tightening torque :

18.6 - 23.5 N*m (1.9 - 2.4 kgf*m, 13.7 - 17.4 lb*ft)

Remove the hydr

Engine And Transaxle Assembly

Engine And Transaxle Assembly

Engine Room Under Cover Repair procedures

Removal

Engine room under cover.

Remove the engine room under cover (A).

Tightening torque :

3.9 - 5.9 N*m (0.4 - 0.6 kgf*m, 2.9 - 4.3 lb*ft)

Install in the reverse order of removal.

Engine Mounting Repair Procedures

Engine Mounting Repair Procedures

Engine Mounting Components and components location

Transaxle mounting bracket

Roll rod bracket

Engine mounting bracket

Engine mounting support bracket

Engine Mounting Repair Procedures

Removal and

Installation

Engine Mounting Brac

SEE MORE:

Tire Pressure Monitoring System

Tire Pressure Monitoring System

Tire Pressure Monitoring System / Components And Components Location

BCM (TPMS)

TPMS Sensor (FL)

TPMS Sensor (RL)

TPMS Sensor (RR)

TPMS Sensor (FR)

Description

TREAD Lamp

Tire Under Inflation / Leak Warning.

Turn on c

Air Bleeding Tool Removal Procedure

Air Bleeding Tool Removal Procedure

Close the air shut-off valve (A) first, after disconnecting the air hose

(B), bleed air in the reservoir tank by opening the air shut-off valve

(A) slowly.

Warning

To prevent backflow of brake fluid, be sure to open the air shut-off

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us