KIA Niro: Hybrid Drive Motor Assembly Components and components location, Repair procedures

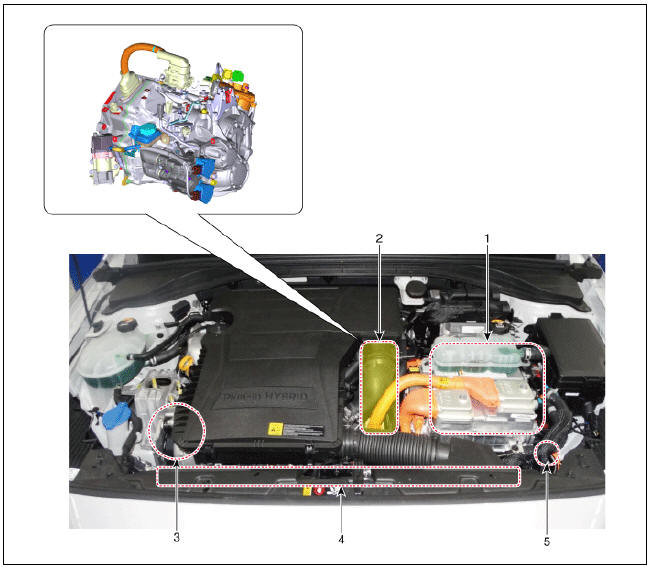

Component

location!

- HPCU (Hybrid Power Control Unit) (LDC+MCU+HCU+Reservoir)

- Hybrid drive motor

- Hybrid starter generator (HSG)

- Electrical radiator

- Electric water pump (EWP)

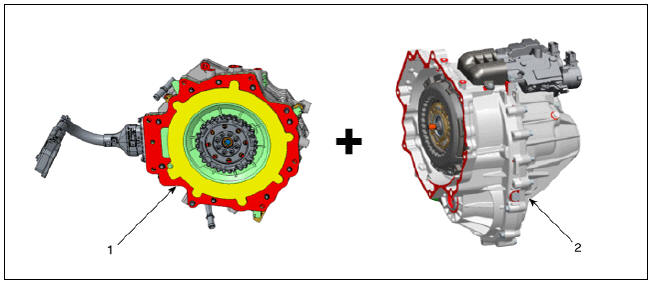

Components

- Hybrid motor assembly

- Double clutch transmission (DCT)

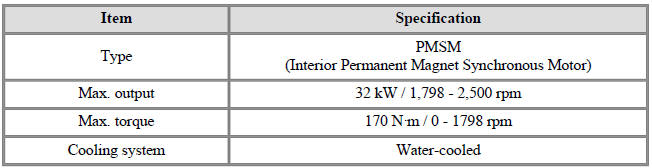

Specification

Hybrid Drive Motor Assembly Repair procedures

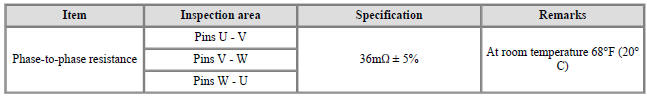

Inspection

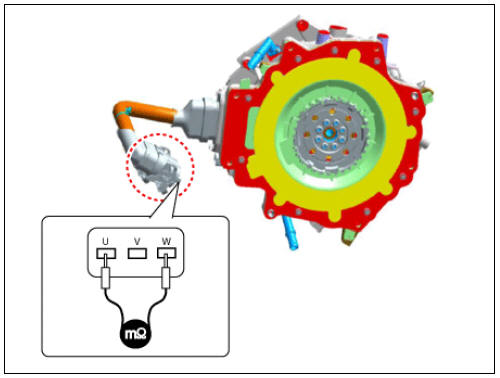

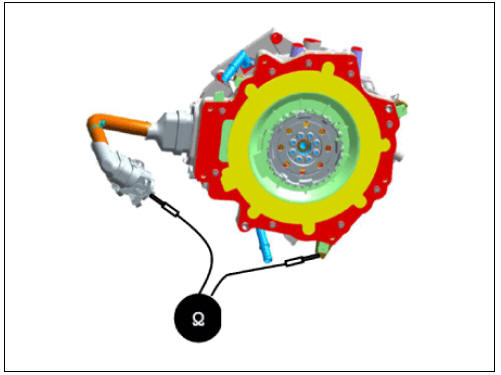

- Using mΩ tester, measure the line-to-line resistance.

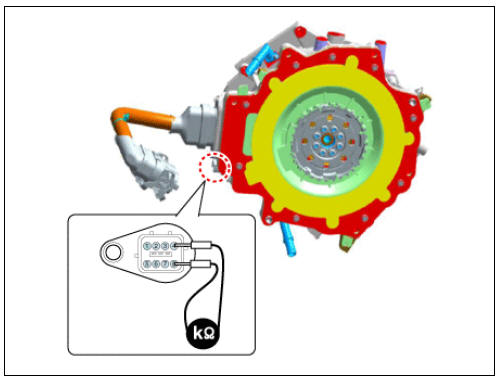

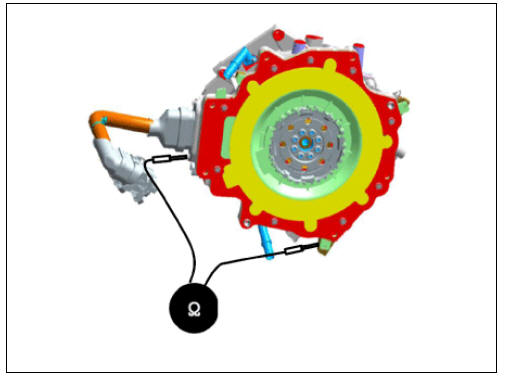

- Inspect the temperature sensor resistance.

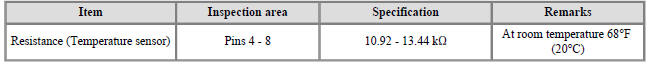

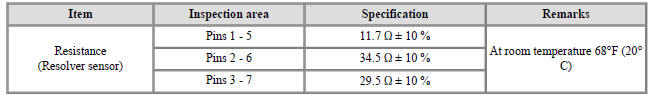

- Inspect the resolver sensor resistance.

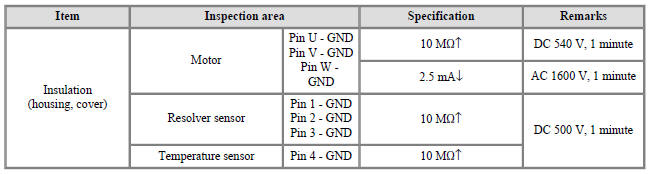

- Inspect the insulation resistance.

Removal

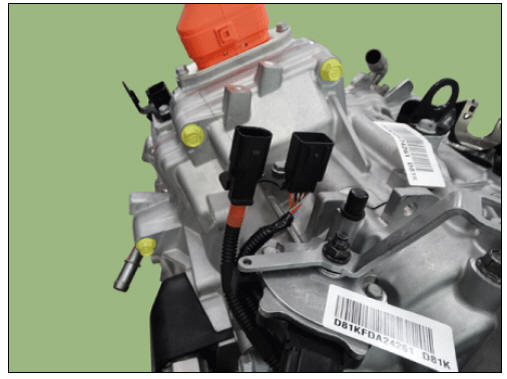

- Remove the hybrid drive motor & dual clutch transmission assembly from the vehicle.

(Refer to DCT System - "DCT(Double Clutch Transmission) System")

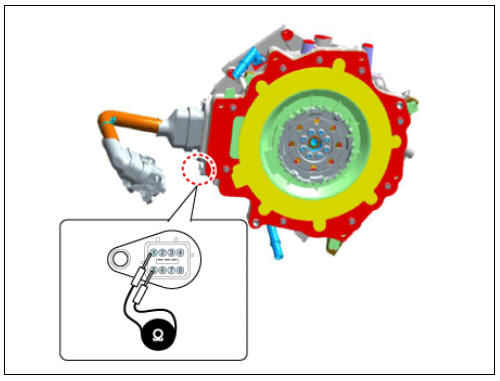

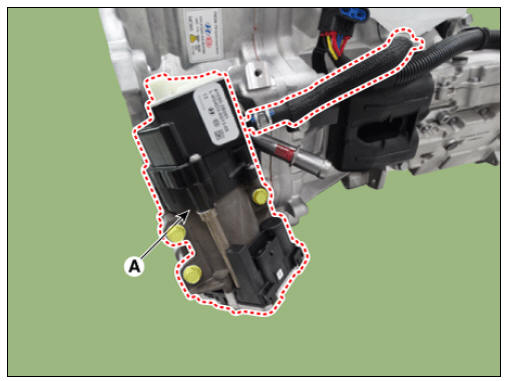

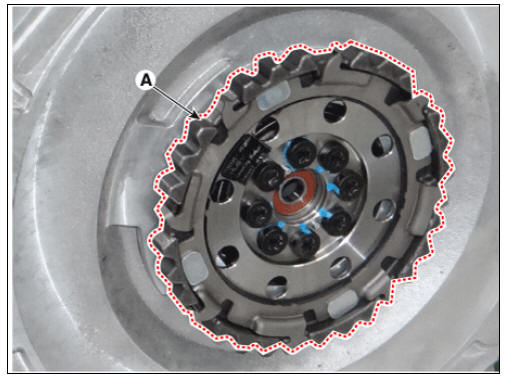

- Remove the engine clutch actuator (A).

Tightening torque : 21.6 - 26.5 N*m (2.2 - 2.7 kgf*m, 15.9 - 19.5 lb*ft)

- Remove the concentric slave cylinder.

(Refer to Clutch System - "Concentric Slave Cylinder Assembly")

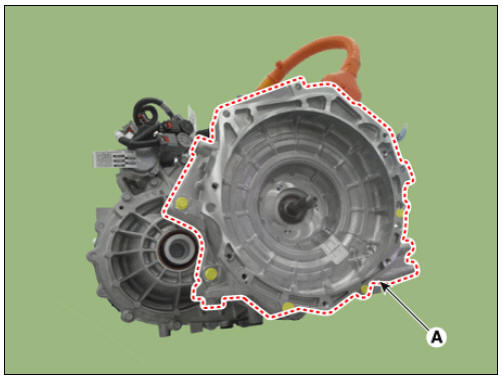

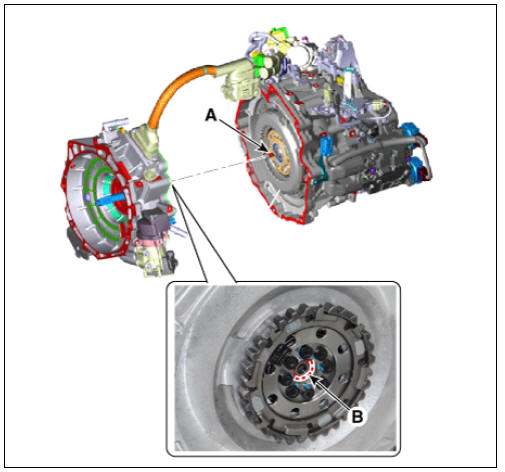

- Remove the hybrid drive motor (A) by loosening the bolts.

Tightening torque : 42.2 - 53.9 N*m (4.3 - 5.5 kgf*m, 31.1 - 39.8 lb*ft)

Installation

- Install in the reverse order of removal.

Warning

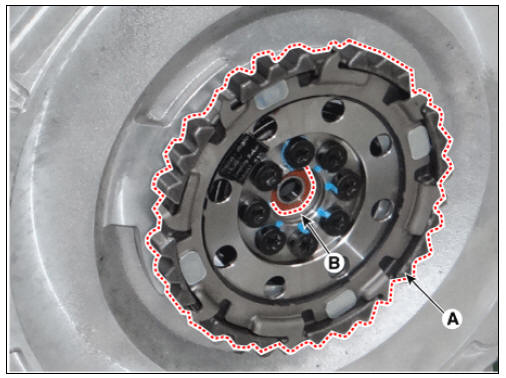

1) Check the pilot bearing (B) and motor side connector (A) on the side of engine for any dents, damages and deformations before installing the DCT.

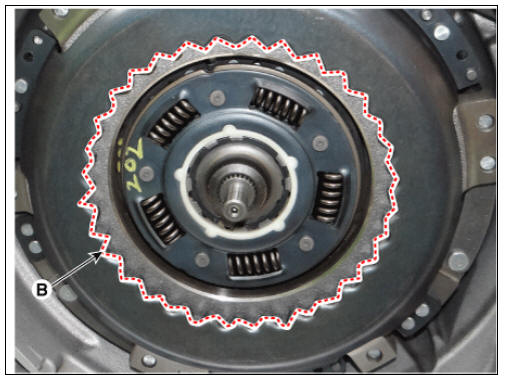

2) Align the motor side connector spline (A) with the dual clutch spline (B).

3) Insert the input shaft (A) into the pilot bearing (B) and then assemble the DCT to the bushing on the motor side.

4) After mounting the DCT to the engine by pushing the DCT, tighten the mounting bolts making sure that there is no gap (less than 2 mm) between the clutch housing and the engine block.

(If the bolt is tightened while there is a gap, then the spline of motor side connector or clutch will be damaged or broken.)

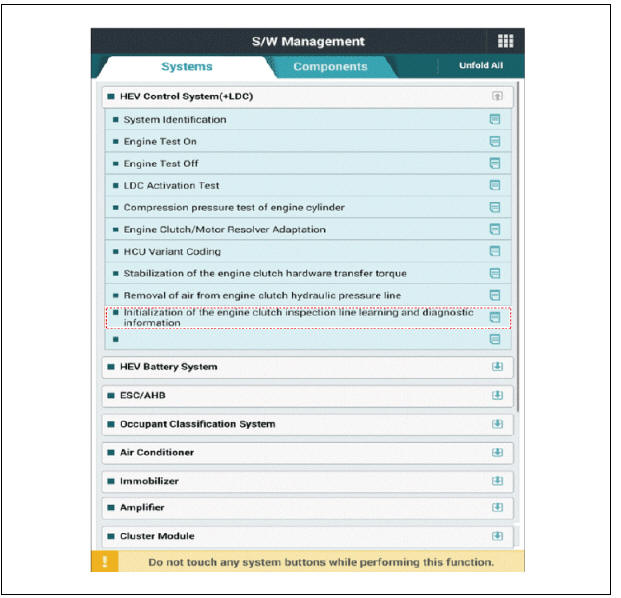

- Perform the procedure below after installing.

(1) Refill the hybrid motor cooling system with coolant and then perform the air bleeding using the KDS.

(Refer to Hybrid Motor System - "Coolant") (2) Perform learning of the engine clutch inspection line and initialization of diagnostic information using the KDS.

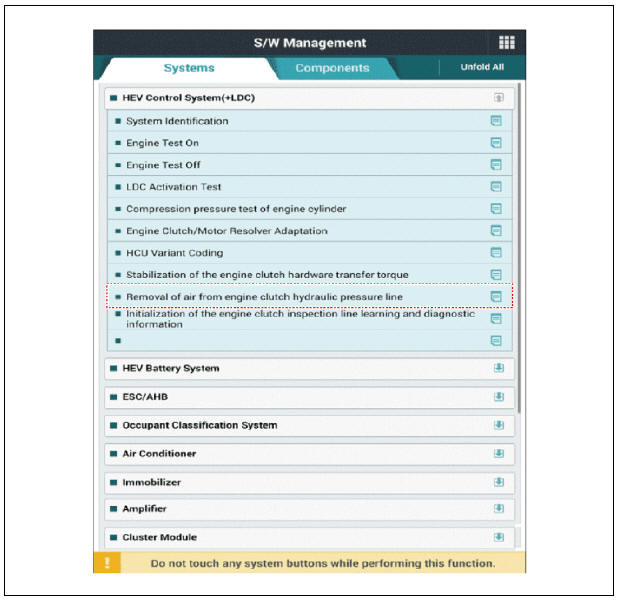

(3) Refill the engine clutch reservoir with brake fluid and then perform the air bleeding using the KDS.

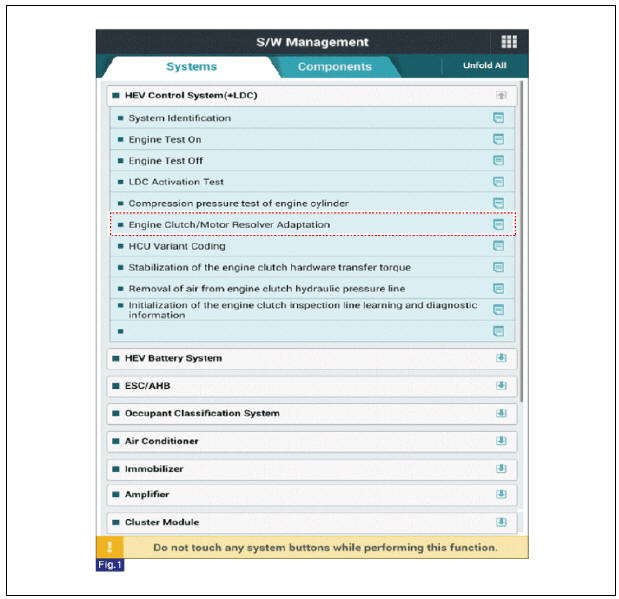

(4) Perform the engine clutch / motor resolver adaptation using the KDS.

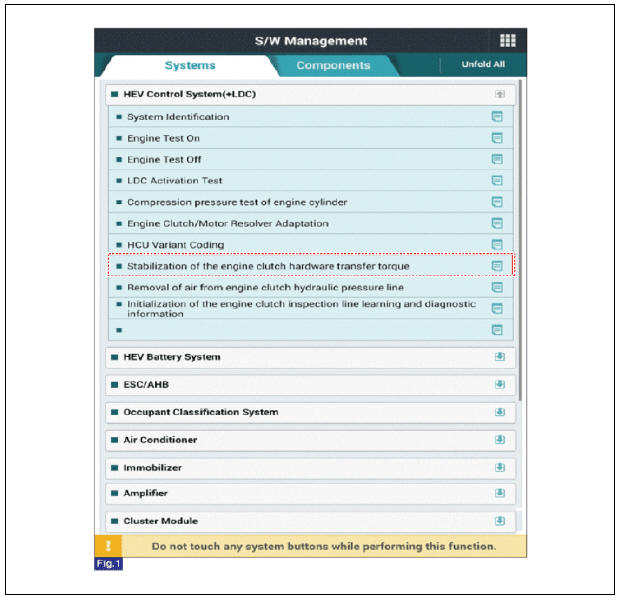

(5) Stabilize the engine clutch hardware transfer torque using the KDS.

READ NEXT:

Hybrid Starter Generator(HSG)

Hybrid Starter Generator(HSG)

Component location

HPCU (Hybrid Power Control Unit)

(LDC+MCU+HCU+Reservoir)

Hybrid drive motor

Hybrid starter generator (HSG)

Electrical radiator

Electric water pump (EWP)

Specification

Inspection

Inspect the line to lin

Hybrid Motor Control System

Hybrid Motor Control System

Description

The Hybrid Power Control Unit (HPCU), composed of various components, is

the core device among the Power Electronics

devices that acts as the brain.

It comprises of the Hybrid Control Unit (HCU), an inverter Motor Control

Un

SEE MORE:

Closing the fuel filler door

Closing the fuel filler door

Operation

Turn the fuel tank cap (2) clockwise

until it "clicks".

Press the rear center edge to close

the fuel filler door (1).

Ensure all the doors and the fuel filler

door are locked.

WARNING

Automotive fuels are flammab

Fender Garnish / Quarter Garnish Repair procedures, Front / Rear Wheel Guard Repair procedures

Fender Garnish / Quarter Garnish Repair procedures, Front / Rear Wheel Guard Repair procedures

Fender Garnish Repair procedures

Replacement

Warning

Put on gloves to protect your hands.

Warning

Use a plastic panel removal tool to remove interior trim pieces without marring the surface.

Be careful not to bend or scratch the tri

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us