KIA Niro: Oil Cooler Repair procedures | Oil Pressure Switch Repair procedures

Removal

- Remove the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

- Drain the engine oil and then remove the oil filter.

(Refer to Lubrication System - "Engine Oil")

- Drain the coolant.

(Refer to Cooling System - "Coolant")

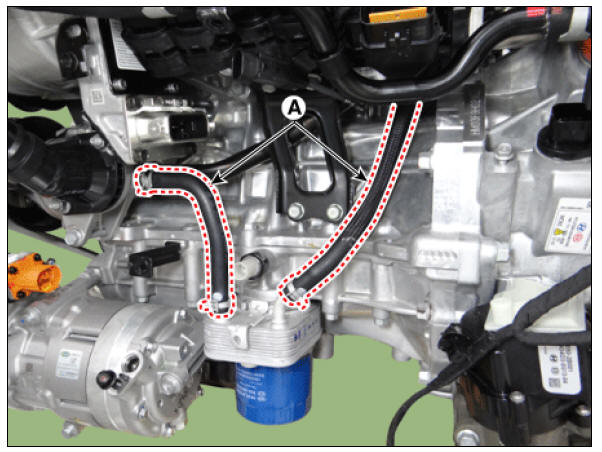

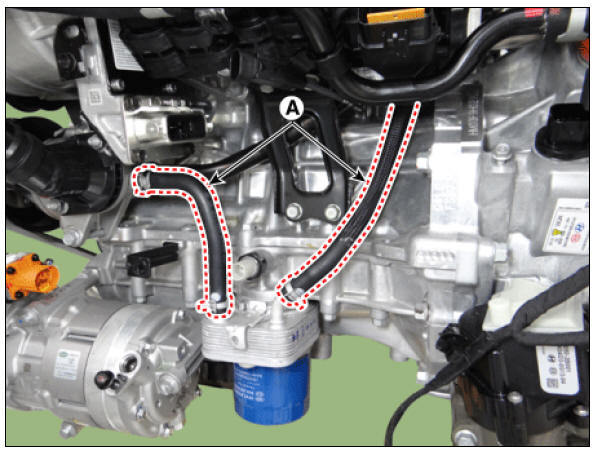

- Disconnect the coolant hose (A).

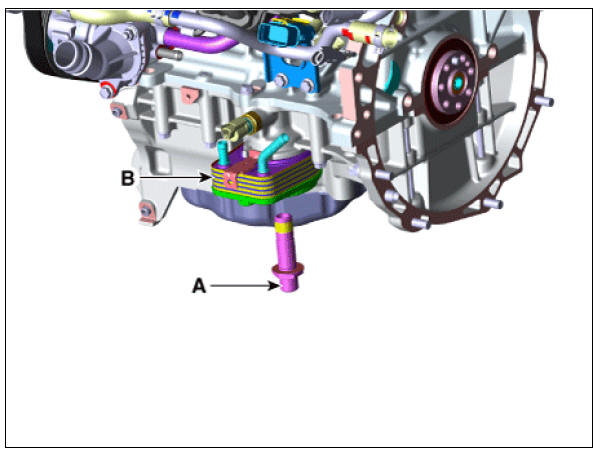

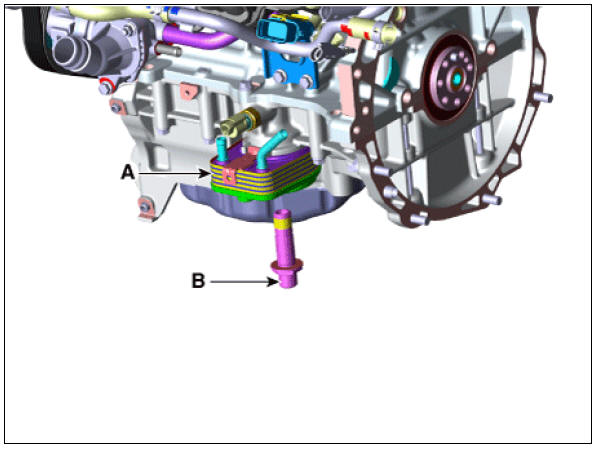

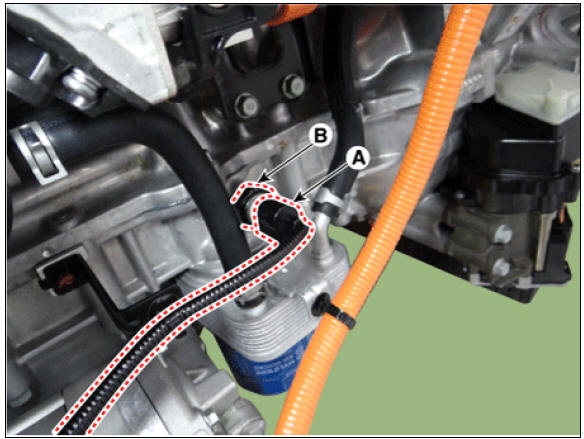

- Unfasten the fixing bolt (A) and then remove the oil cooler assembly (B).

Installation

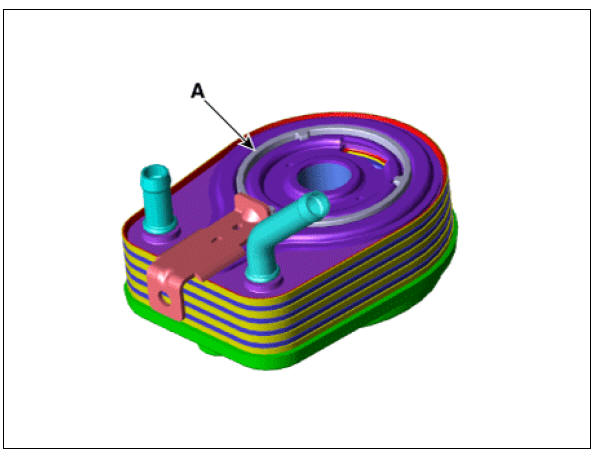

- Apply engine oil to the oil cooler packing surface (A).

- Install the oil cooler (A) with a fixing bolt (B).

Tightening torque : 50.1 - 55.9 N*m (5.1 - 5.7 kgf*m, 36.9 - 41.2 lb*ft)

Warning

Fix position of oil cooler stopper where oil cooler resists on ladder frame stopper.

- Connect the coolant hose (A).

- Fill the coolant.

(Refer to Cooling System - "Coolant")

- Install the oil filter and then fill the engine oil.

(Refer to Lubrication System - "Engine Oil")

- Install the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

Oil Pressure Switch Repair procedures

Removal and

Installation

- Disconnect the battery negative terminal.

- Remove the engine room under cover.

(Refer to Engine and Transaxle Assembly - "Engine Room Under Cover")

- Disconnect the oil pressure switch connector (A).

- Remove the oil pressure switch (B).

Tightening torque : 9.8 - 11.8 N*m (1.0 - 1.2 kgf*m, 7.2 - 8.7 lb*ft)

- Install in the reverse order of removal.

Warning

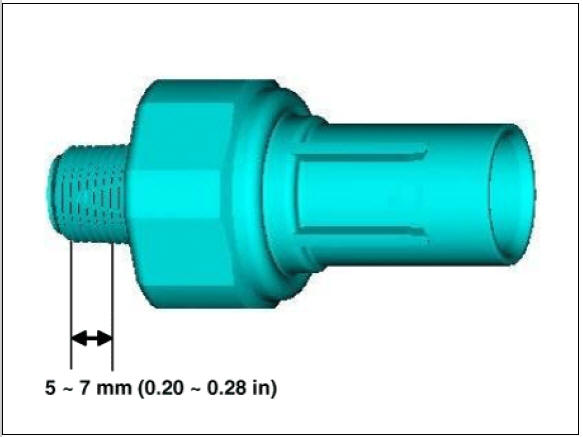

When installing the oil pressure switch, apply seal lock to the thread.

Seal lock : THREEBOND 2403

Thickness : 0.2 - 0.4 mm (0.008 - 0.016 in.)

Inspection

- Check the continuity between the terminal and the body with an ohmmeter.

If there is no continuity, replace the oil pressure switch.

- Check the continuity between the terminal and the body when the fine wire is pushed. If there is continuity even when the fine wire is pushed, replace the switch.

- If there is no continuity when a pressure of 50 kPa (0.50 kgf/cm², 7.25 psi) is applied through the oil hole, the switch is operating properly.

Check for air leakage. If air leaks, the diaphragm is broken. Replace it.

Oil Level Gauge & Pipe Repair procedures

Removal and

Installation

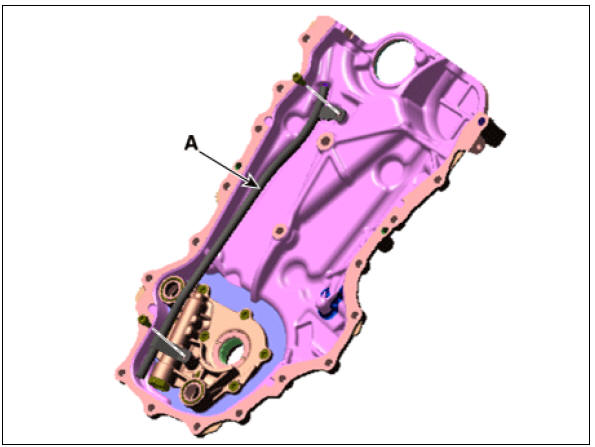

- Remove the oil level gauge (A).

- Remove the timing chain cover.

(Refer to Timing System - "Timing Chain Cover") 3. Remove the Oil level gauge pipe (A).

Tightening torque : 8.8 - 13.7 N*m (0.9 - 1.4 kgf*m, 6.5 - 10.1 lb*ft)

- Install in the reverse order of removal.

Removal and

Installation

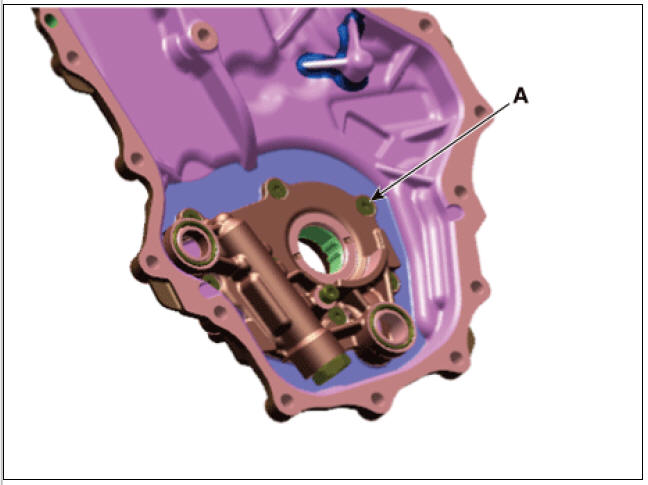

Warning

Do not disassemble the oil pump (A) from timing chain cover because it is supplied as timing chain cover & oil pump assembly.

READ NEXT:

Front Oil Seal Repair procedures | Timing Chain Cover Repair procedures

Front Oil Seal Repair procedures | Timing Chain Cover Repair procedures

Components

Front oil seal

Timing chain cover

Variable force solenoid (VFS) valve

O-ring

Timing chain tensioner

Timing chain tensioner arm

Timing chain guide

Timing chain

Timing chain cam guide

Front

SEE MORE:

Start/Stop Button | ESCL (Electronic Steering Column Lock)

Start/Stop Button | ESCL (Electronic Steering Column Lock)

Start/Stop Button Repair procedures

Removal

Disconnect the negative (-) battery terminal.

Remove the crash pad garnish assembly (RH). (Refer to Body - "Crash Pad Garnish (RH)")

Remove the start/stop button.

(1) Push

Rear Bumper Assembly

Rear Bumper Assembly

Rear bumper assembly

Replacement

Warning

Put on gloves to protect your hands.

Warning

Use a plastic panel removal tool to remove interior trim pieces

without marring the surface.

Be careful not to bend or scratch the trim and pa

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us