KIA Niro: Stop Lamp Switch

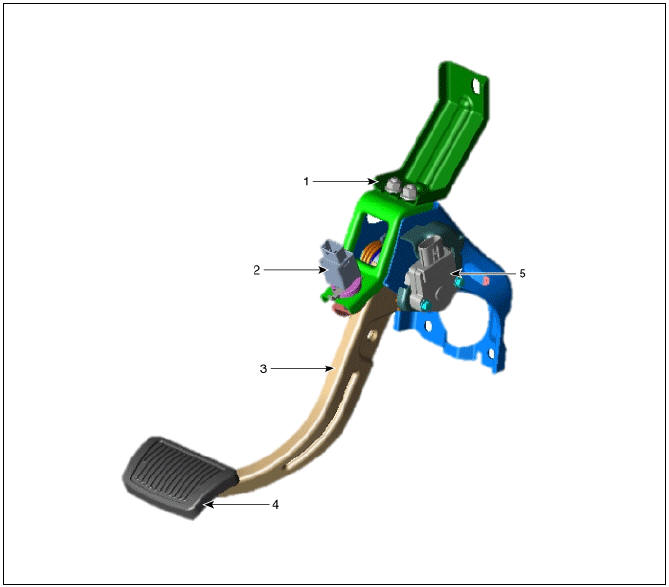

Stop Lamp Switch Components and components location

- Brake pedal member assembly

- Stop lamp switch

- Brake pedal arm

- Brake pedal pad

- Brake pedal stroke sensor

Operation

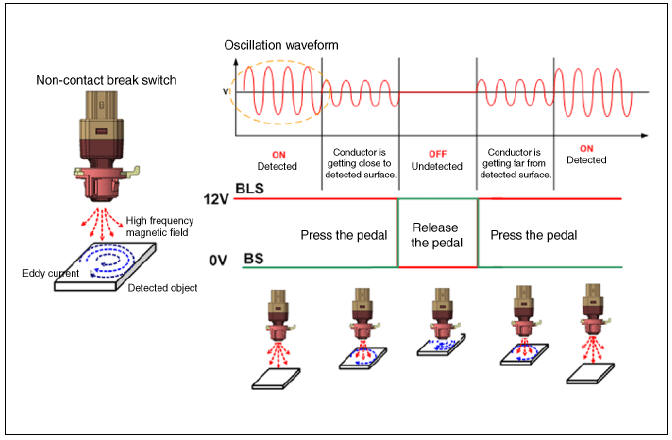

Operation principle of inductive non-contact switch

- Use the high frequency magnetic field and the induced current that are generated by oscillation (to approved voltage) of coil in switch.

- The eddy current is generated on surface of metal by self inductance effect if there is metal in high frequency magnetic field.

- The eddy current that is generated attenuates the high frequency magnetic field as much as amount of generated by disturbing the switch's magnetic flux.

- ON-OFF by judging whether high voltage magnetic field is attenuates or not(calculate the voltage difference by length between metal and coil)

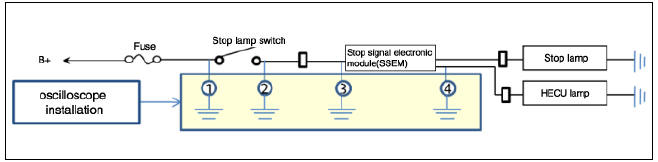

Schematic Diagram

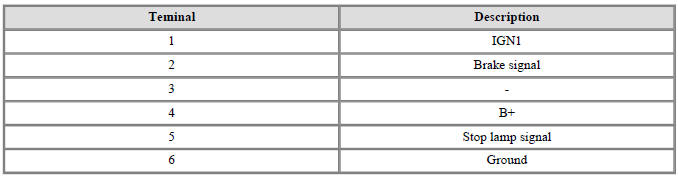

Terminal function

Stop Lamp Switch - Troubleshooting

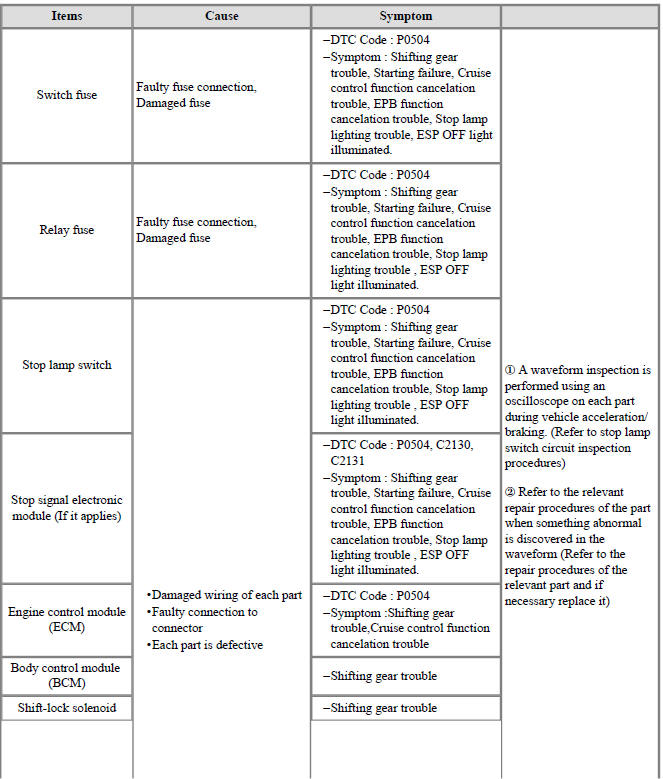

- Part diagnosis

Items:

Switch fuse

Cause:

Faulty fuse connection, Damaged fuse

Symptom:

- DTC Code : P0504

- Symptom : Shifting gear trouble, Starting failure, Cruise control function cancelation trouble, EPB function cancelation trouble, Stop lamp lighting trouble, ESP OFF light illuminated.

Items:

Relay fuse

Cause:

Faulty fuse connection, Damaged fuse

Symptom:

- DTC Code : P0504

- Symptom : Shifting gear trouble, Starting failure, Cruise control function cancelation trouble, EPB function cancelation trouble, Stop lamp lighting trouble , ESP OFF light illuminated.

Items:

Stop lamp switch

Cause:

- Damaged wiring of each part

- Faulty connection to connector

- Each part is defective

Symptom:

- DTC Code : P0504

- Symptom : Shifting gear trouble, Starting failure, Cruise control function cancelation trouble, EPB function cancelation trouble, Stop lamp lighting trouble , ESP OFF light illuminated.

Items:

Stop signal electronic module (If it applies)

Cause:

- Damaged wiring of each part

- Faulty connection to connector

- Each part is defective

Symptom:

- DTC Code : P0504, C2130, C2131

- Symptom : Shifting gear trouble, Starting failure, Cruise control function cancelation trouble, EPB function cancelation trouble, Stop lamp lighting trouble , ESP OFF light illuminated.

Items:

Engine control module (ECM)

Cause:

- Damaged wiring of each part

- Faulty connection to connector

- Each part is defective

Symptom:

- DTC Code : P0504

- Symptom :Shifting gear trouble,Cruise control function cancelation trouble

Items:

Body control module (BCM)

Cause:

- Damaged wiring of each part

- Faulty connection to connector

- Each part is defective

Symptom:

- Shifting gear trouble

Items:

Shift-lock solenoid

Cause:

- Damaged wiring of each part

- Faulty connection to connector

- Each part is defective

Symptom:

- Shifting gear trouble

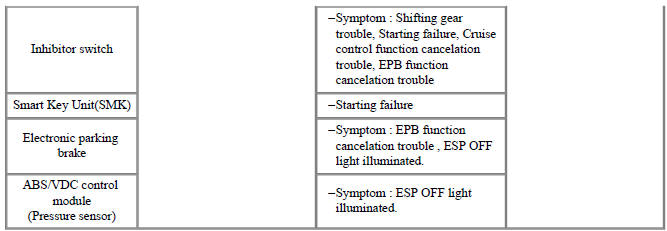

Items:

Inhibitor switch

Cause:

- Damaged wiring of each part

- Faulty connection to connector

- Each part is defective

Symptom:

- Symptom : Shifting gear trouble, Starting failure, Cruise control function cancelation trouble, EPB function cancelation trouble

Items:

Smart Key Unit(SMK)

Cause:

- Damaged wiring of each part

- Faulty connection to connector

- Each part is defective

Symptom:

- Starting failure

Items:

Electronic parking brake

Cause:

- Damaged wiring of each part

- Faulty connection to connector

- Each part is defective

Symptom:

- Symptom : EPB function cancelation trouble , ESP OFF light illuminated.

Items:

ABS/VDC control module (Pressure sensor)

Cause:

- Damaged wiring of each part

- Faulty connection to connector

- Each part is defective

Symptom:

- Symptom : ESP OFF light illuminated.

- A waveform inspection is performed using an oscilloscope on each part during vehicle acceleration/ braking. (Refer to stop lamp switch circuit inspection procedures)

- Refer to the relevant repair procedures of the part when something abnormal is discovered in the waveform (Refer to the repair procedures of the relevant part and if necessary replace it)

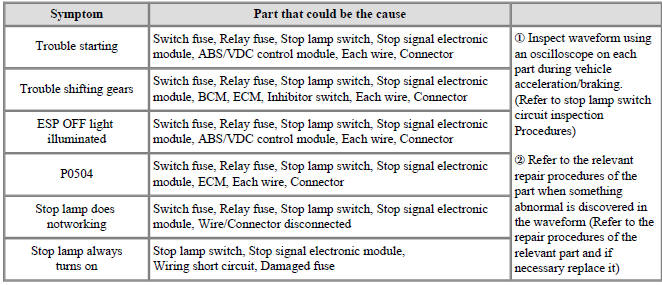

- Symptom diagnosis

Symptom:

Trouble starting

Part that could be the cause:

Switch fuse, Relay fuse, Stop lamp switch, Stop signal electronic module, ABS/VDC control module, Each wire, Connector

Symptom:

Trouble shifting gears

Part that could be the cause:

Switch fuse, Relay fuse, Stop lamp switch, Stop signal electronic module, BCM, ECM, Inhibitor switch, Each wire, Connector

Symptom:

ESP OFF light illuminated

Part that could be the cause:

Switch fuse, Relay fuse, Stop lamp switch, Stop signal electronic module, ABS/VDC control module, Each wire, Connector

Symptom:

P0504

Part that could be the cause:

Switch fuse, Relay fuse, Stop lamp switch, Stop signal electronic module, ECM, Each wire, Connector

Symptom:

Stop lamp does notworking

Part that could be the cause:

Switch fuse, Relay fuse, Stop lamp switch, Stop signal electronic module, Wire/Connector disconnected

Symptom:

Stop lamp always turns on

Part that could be the cause:

Stop lamp switch, Stop signal electronic module, Wiring short circuit, Damaged fuse

- Inspect waveform using

an oscilloscope on each

part during vehicle

acceleration/braking.

(Refer to stop lamp switch circuit inspection Procedures)

- Refer to the relevant repair procedures of the part when something abnormal is discovered in the waveform (Refer to the repair procedures of the relevant part and if necessary replace it)

3. Stop lamp switch system diagnosis

SSEM : Stop Signal Electronic Module

- Refer to DTC guide when the related DTC codes are displayed.

READ NEXT:

Stop Lamp Switch Repair procedures

Stop Lamp Switch Repair procedures

Removal

Turn ignition switch OFF and disconnect the negative (-) battery

terminal.

Remove the crash pad lower panel.

(Refer to Body - "Crash Pad")

Remove the knee air bag.

(Refer to Restraint - "Knee Airbag(KAB) Module&q

SEE MORE:

Shift dial SBW type

Shift dial SBW type

P (Park)

R (Reverse)

N (Neutral)

D (Drive)

Operation

Depress the brake pedal and turn the

knob to the desired position.

Press P button to shift to P (Park).

Transmission ranges

The indicator in the instrument cluster

Rear / Front Inlet Cooling Duct

Rear / Front Inlet Cooling Duct

Removal

Warning

Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical inj

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us