KIA Niro: Battery Pack Assembly Repair procedures

Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual / Service Highlight / High Voltage Battery System / Battery Pack Assembly Repair procedures

Disassembly

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to shut off the high voltage before doing any work related with the high voltage system(Refer to "High Voltage Shut-off Procedure"). Failure to follow the safety instructions may result in serious electrical injuries.

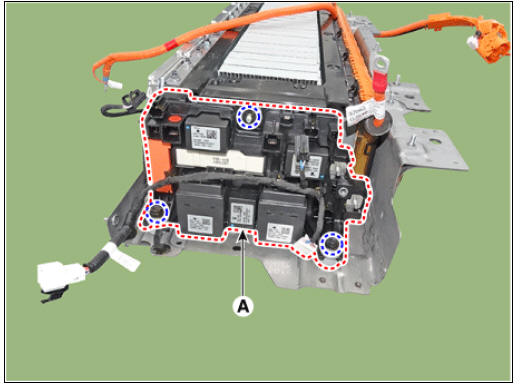

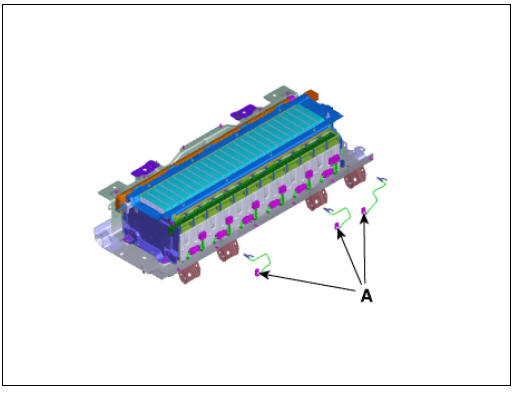

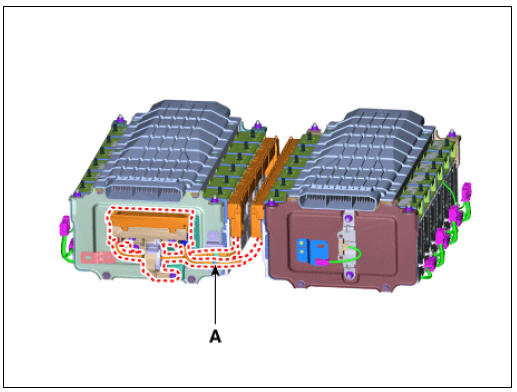

- Remove the high voltage battery front cover (A).

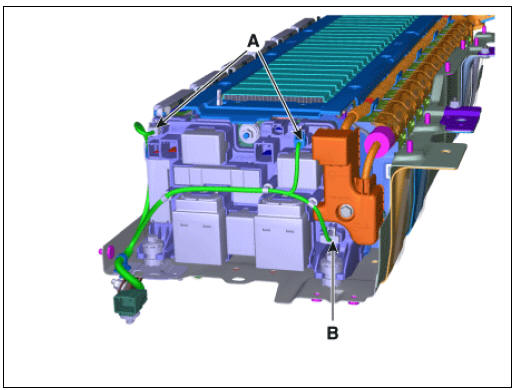

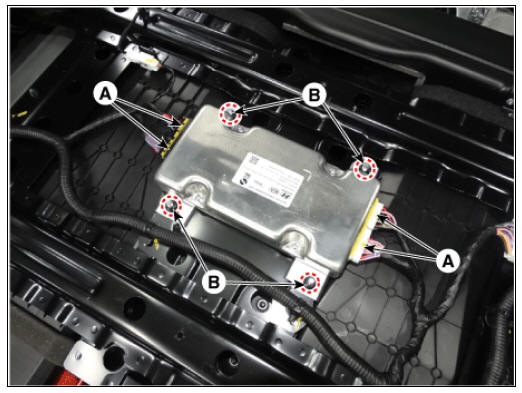

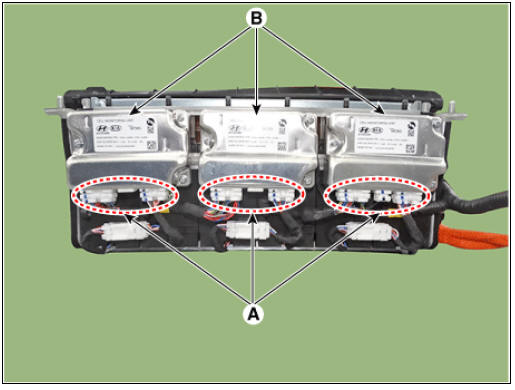

- Disconnect the OBC relay connector (A) and PRA connector (B).

- Remove the high voltage cable cover (A).

- Disconnect the battery current sensor connector (A).

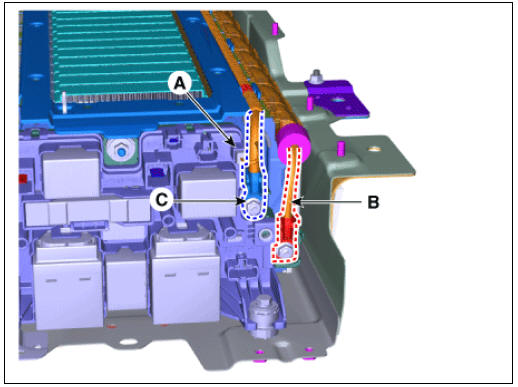

- Disconnect the high voltage power cable (+) terminal (A) and (-) terminal (B) after loosening the mounting nuts.

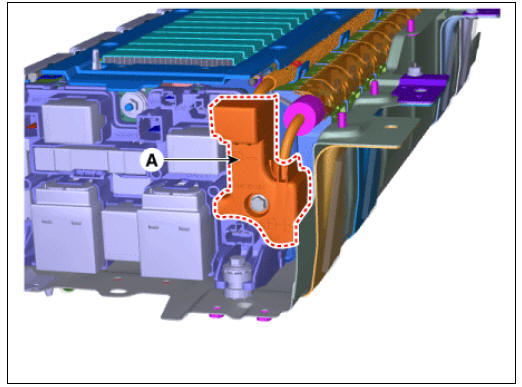

- Remove the power relay assembly (A) after loosening the mounting bolts and nuts.

- Disconnect the inlet temperature sensor connector (A) and then remove the inlet temperature sensor (B).

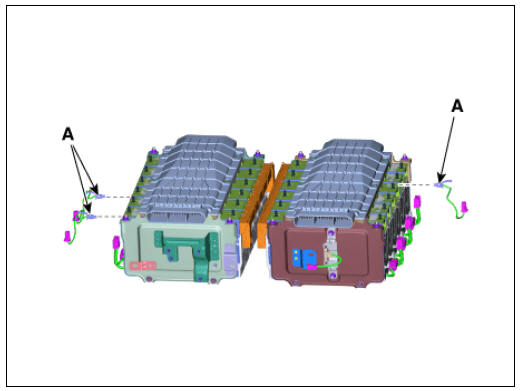

- Disconnect the cell monitoring unit connector (A).

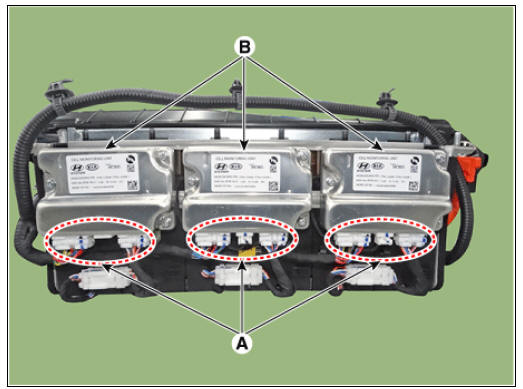

- Remove the cell monitoring unit (CMU) (B) after loosening the mounting nuts and screw.

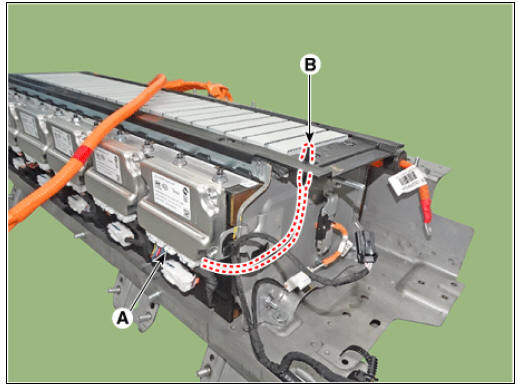

- Remove the high voltage cable (B) after loosening the ground bolts (A).

- Remove the battery temperature sensor (A).

- Remove the air duct (A).

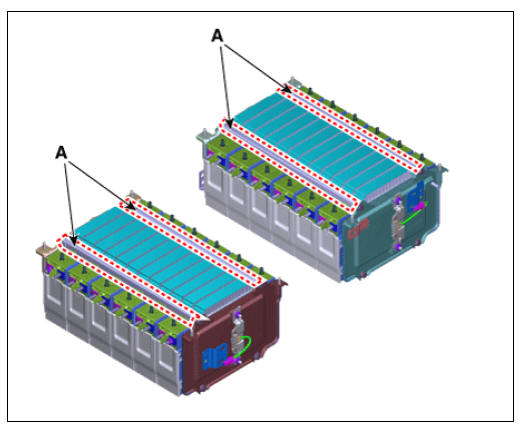

- Remove the bus bar (A) after loosening the mounting nuts.

- Remove the cell monitoring unit bracket (A) after loosening the mounting nuts.

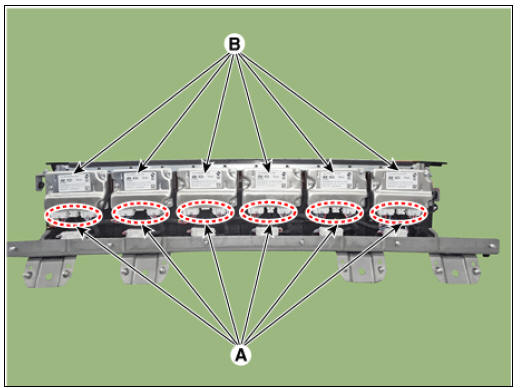

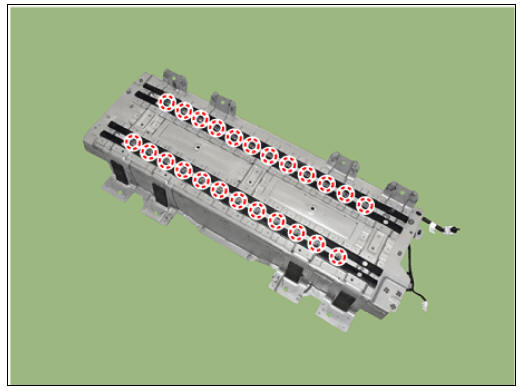

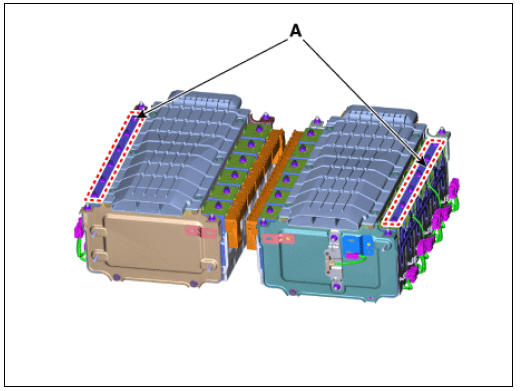

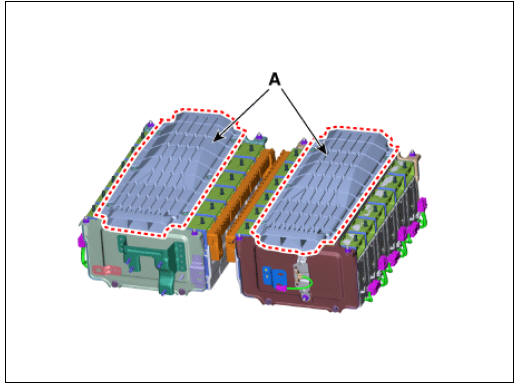

- Remove the battery module mounting nuts.

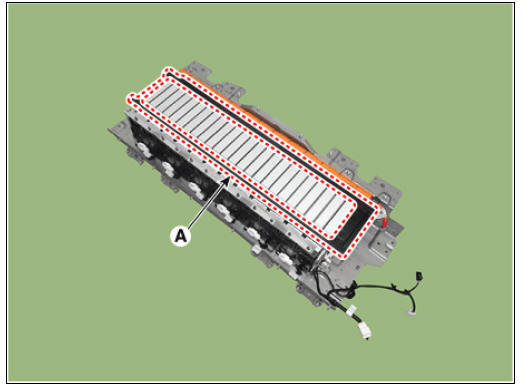

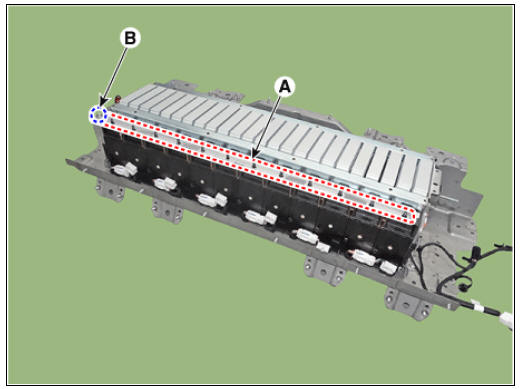

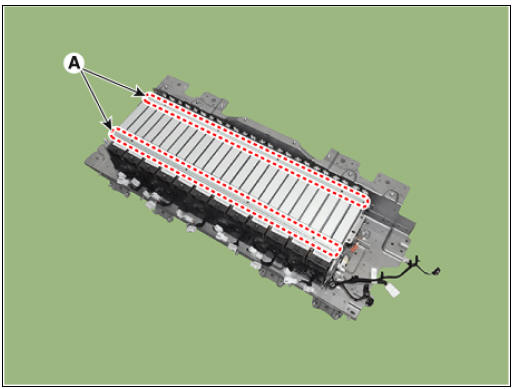

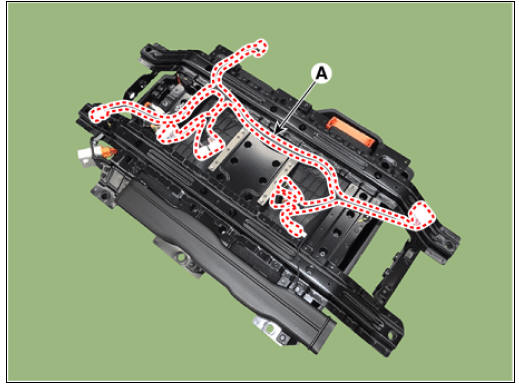

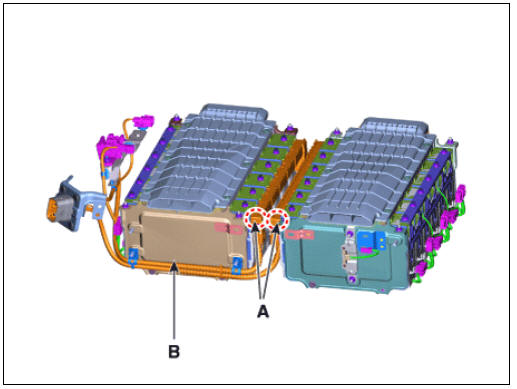

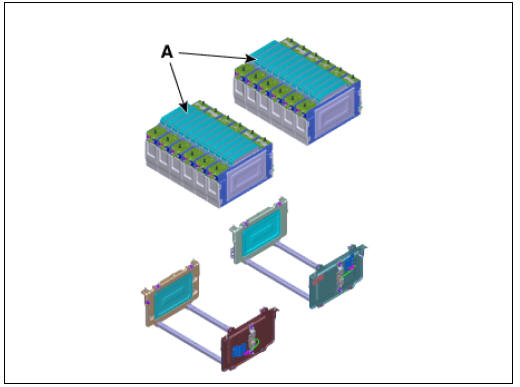

- Remove the main battery pack support bar (A).

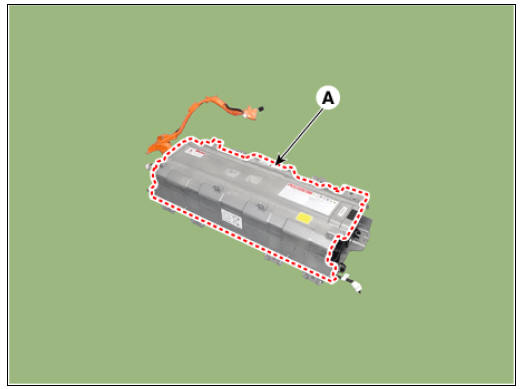

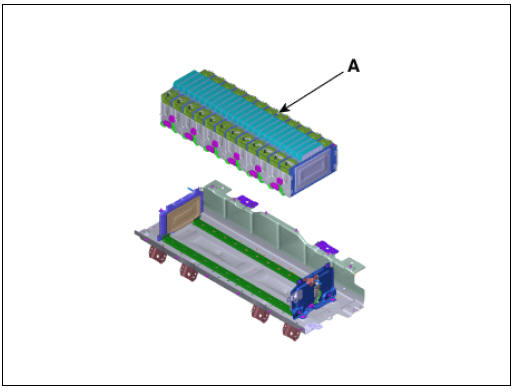

- Remove the sub high voltage battery module (A) from the battery plate.

Sub Battery Pack Assembly

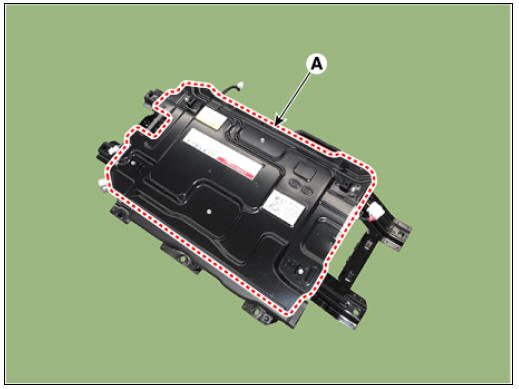

- Remove the high voltage battery cover (A) after loosening the bolts.

- Disconnect the BMS connector (A).

- Remove the BMS after loosening the bolts (B).

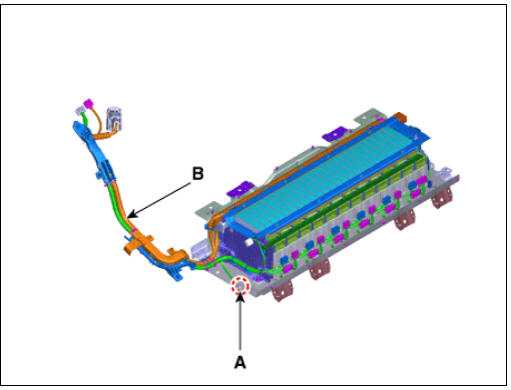

- Remove the BMS wiring harness (A).

- Remove the outlet duct (A).

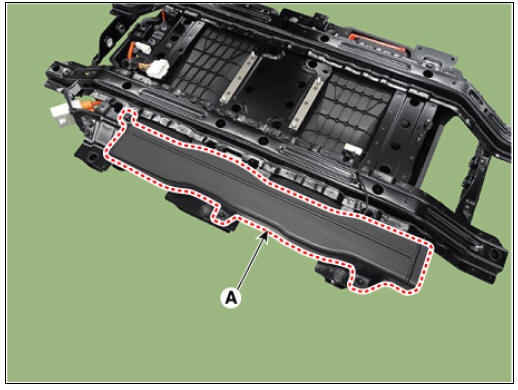

- Remove the watertight case (A) after loosening the bolts.

- Disconnect the cell monitoring unit connector (A).

- Remove the cell monitoring unit (B) after loosening the screw.

- Remove the high voltage cable (B) after loosening the nuts (A).

- Remove the cell monitoring unit bracket (A) after loosening the nuts.

- Remove the main fuse assembly (A) after loosening the nuts.

- Remove the battery temperature sensor (A).

- Remove the air duct (A).

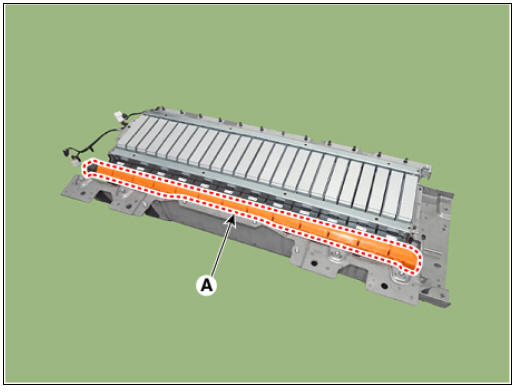

- Remove the sub battery pack support bar (A).

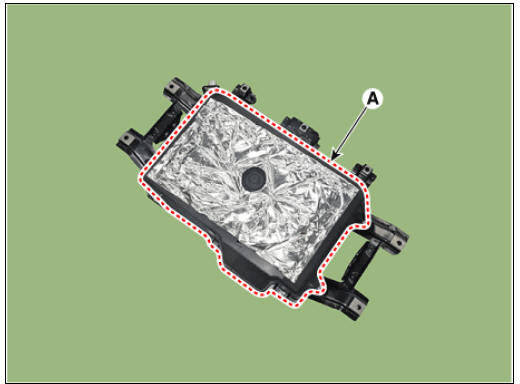

- Remove the sub high voltage battery module (A) from the battery plate.

Reassembly

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to shut off the high voltage before doing any work related with the high voltage system(Refer to "High Voltage Shut-off Procedure"). Failure to follow the safety instructions may result in serious electrical injuries.

- Install the battery pack assembly in the reverse order of removal.

READ NEXT:

Battery Pack Assembly Troubleshooting Chart

Battery Pack Assembly Troubleshooting Chart

Inspection

Warning

For SOC check, refer to "SOC Inspection"

For voltage check, refer to "Battery Voltage Inspection"

For battery voltage sensing circuit, refer to "Voltage Sensing

Circuit Inspection"

Fo

Power Relay Assembly (PRA)

Power Relay Assembly (PRA)

PRA Operation Sequence

Description

The Power Relay Assembly (PRA) consists of the positive and negative main

relays, pre-charge relay, pre-charge resistor and

battery current sensor. It is located inside the battery pack assembly and

controls

Main High/ Sub High Voltage Battery

Main High/ Sub High Voltage Battery

Main High Voltage Battery

Component Location

Power Relay Assembly (PRA)

Cell Monitoring Unit (CMU)

Battery Temperature Sensor

Runaway Arresting Device (RAD)

Warning

Main Relays (Positive, Negative), Pre-Charge Relay, Pre-Charge

R

SEE MORE:

In the event of brake failure (Kia Niro EV)

In the event of brake failure (Kia Niro EV)

Operation

Make an emergency stop with the

parking brake.

Operating condition(s)

The brake has failed

Power-assisted brakes

Operation

Apply greater force to the brake

pedal.

Operating condition(s)

The vehicle is stalled

How to check the symbol on the charging label (For Europe) (if equipped)

How to check the symbol on the charging label (For Europe) (if equipped)

Vehicle charging INLET

Charging connector OUTLET

Symbol location and application example

Precautions for charging AC and Trickle charger (Portable charging

cable) (AC charging)

After opening the charging door, check the chargi

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us