KIA Niro: Power Relay Assembly (PRA)

PRA Operation Sequence

Description

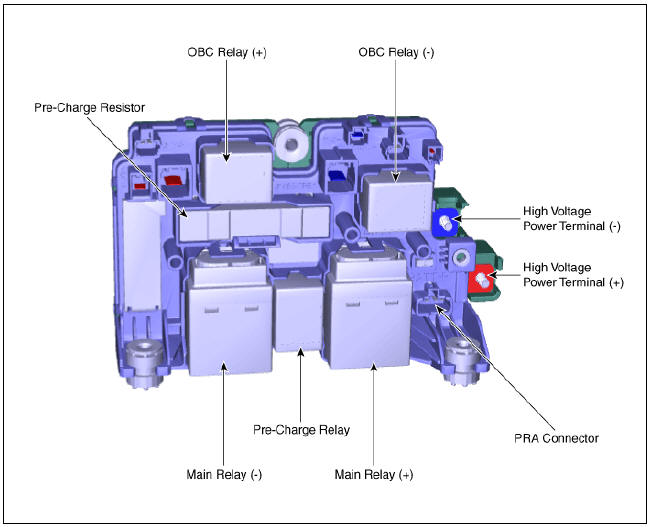

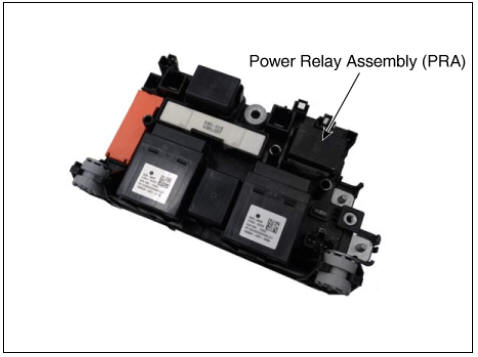

The Power Relay Assembly (PRA) consists of the positive and negative main relays, pre-charge relay, pre-charge resistor and battery current sensor. It is located inside the battery pack assembly and controls the high voltage power circuit between the high voltage battery and inverter by the control signal of BMS ECU.

PRA Operation Sequence

High Voltage Battery System / Repair Procedures

Removal

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to read and follow the "High Voltage Shut-off Procedures" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Shut off the high voltage.

(Refer to "High voltage Shut-off Procedures")

- Remove the rear seat cushion.

(Refer to Body - "Rear Seat Assembly")

- Remove the rear door scuff trim.

(Refer to Body - "Door Scuff Trim")

- Remove the inlet cooling duct.

(Refer to High Voltage Battery Cooling System - "Cooling Duct")

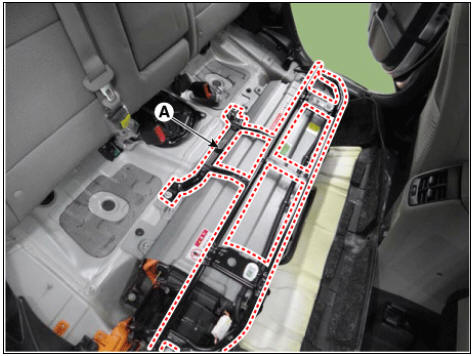

- Open the floor carpet (A) to the arrow direction.

- Remove the upper frame (A) after loosening the mounting bolts and nuts.

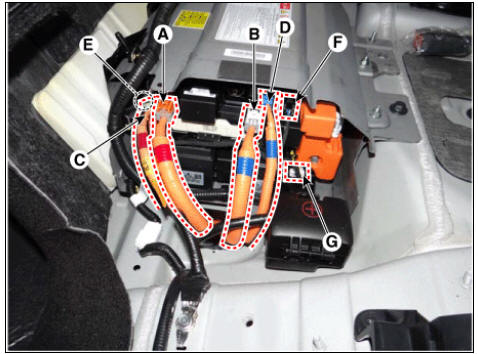

- Disconnect the connectors in the illustration below.

- Inverter power connector (+)

- Inverter power connector (-)

- OBC power connector (+)

- OBC power connector (-)

- OBC relay connector (+)

- OBC relay connector (-)

- PRA relay connector

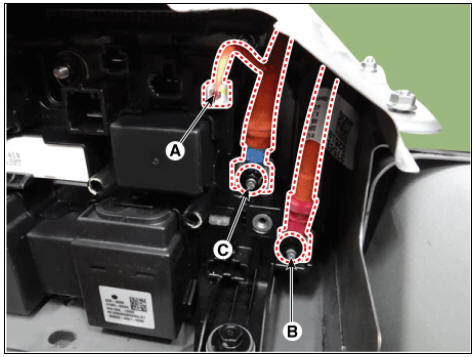

- Disconnect the battery current sensor connector (A).

- Disconnect the high voltage power cable (+) terminal (B) and (-) terminal (C).

High voltage power cable terminal tightening nut : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

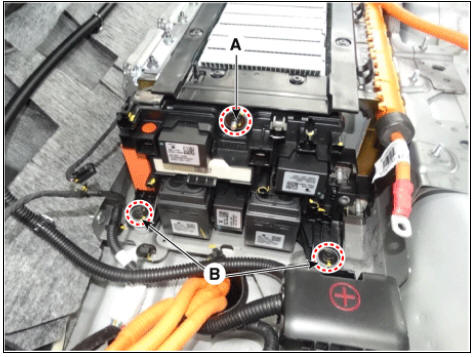

- Remove the power relay assembly (RPA) after loosening the mounting nut (A) and bolt (B).

PRA mounting nut : 7.8 - 11.8 N.m (0.8 - 1.2 kgf.m, 5.8 - 8.7 lb-ft)

Installation

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to read and follow the "High Voltage Shut-off Procedures" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Install the power relay assembly in the reverse order of removal.

Description

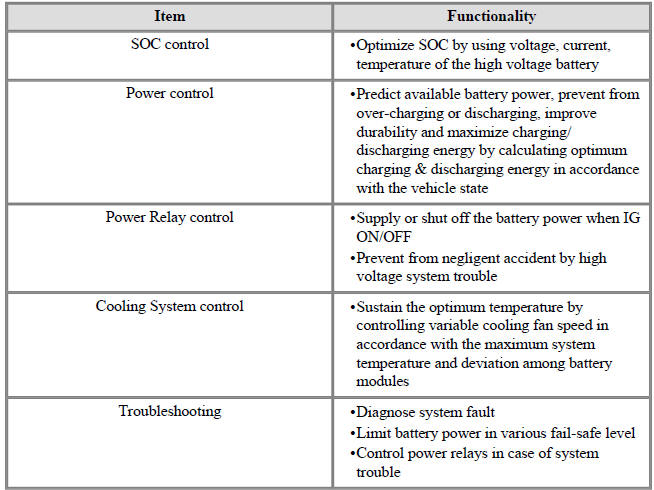

The high voltage battery system consists of the BMS ECU (Battery Management

System ECU), Power

Relay Assembly (PRA), safety plug, battery temperature sensor, and battery

ambient sensor.

Especially the BMS ECU controls SOC (State Of Charge), power, cell balancing,

cooling and

Troubleshooting of the high voltage battery system.

The PRA includes main relays (positive, negative), pre-charge relay, pre-charge

resistor and battery

current sensor.

Main Functionalities

Warning

SOC (State Of Charge): available energy of the high voltage battery

- Main High/ Sub High Voltage Battery

- Sub High Voltage Battery - Removal

- Safety Plug Description and operation

- The Power Relay Assembly

READ NEXT:

Main High/ Sub High Voltage Battery

Main High/ Sub High Voltage Battery

Main High Voltage Battery

Component Location

Power Relay Assembly (PRA)

Cell Monitoring Unit (CMU)

Battery Temperature Sensor

Runaway Arresting Device (RAD)

Warning

Main Relays (Positive, Negative), Pre-Charge Relay, Pre-Charge

R

Sub High Voltage Battery - Removal

Sub High Voltage Battery - Removal

Warning

Be sure to read and follow the "General Safety Information and

Caution" before doing any work related

with the high voltage system. Failure to follow the safety instructions may

result in serious electrical

injuries.

Safety Plug Description and operation

Safety Plug Description and operation

Description

Safety Plug is installed on the rear side of the high voltage battery and it

can mechanically shut the

high voltage circuit off when servicing the high voltage system. (i.e. High

Voltage Battery, Power

Relay Assembly, HPCU, BMS ECU

SEE MORE:

Front View Camera Unit

Front View Camera Unit

Front view camera unit

LKA ON/OFF switch

Description

System Function

Lane Keeping Assist (LKA) : The function detects unintentional lane

departure and assists to keep the lane by using alarms

and MDPS steering control.

High Be

Jump-starting (12V battery) (Kia Niro EV)

Jump-starting (12V battery) (Kia Niro EV)

Jump-starting (12V battery)

Condition(s)

When the vehicle will not start due to

low battery power

Operation

Connect the jumper cables as shown.

Positive (+) terminal of the flat battery

(1) and the booster battery (2).

Neg

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us