KIA Niro: The Power Relay Assembly

Description

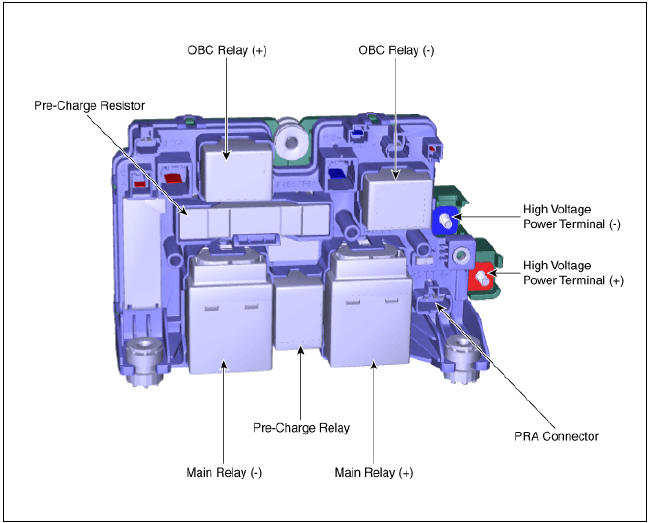

The Power Relay Assembly (PRA) consists of the positive and negative main relays, pre-charge relay, pre-charge resistor and battery current sensor. It is located inside the battery pack assembly and controls the high voltage power circuit between the high voltage battery and inverter by the control signal of BMS ECU.

PRA Operation Sequence

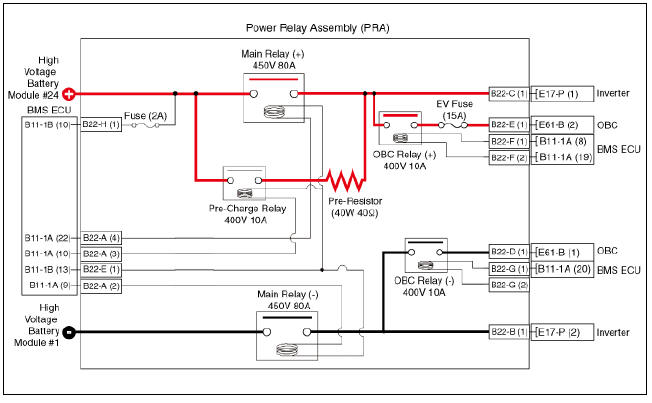

Circuit Diagram

Removal

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to read and follow the "High Voltage Shut-off Procedures" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries

- Turn ignition switch OFF and disconnect the negative (-) battery cable.

- Shut off the high voltage circuit.

(Refer to Hybrid Control System - "High Voltage Shut-off Procedures")

- Remove the power relay assembly.

(Refer to High Voltage Battery System - "Power Relay Assembly")

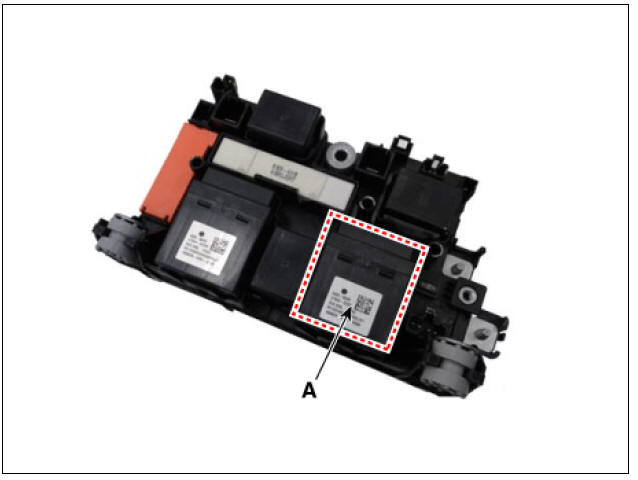

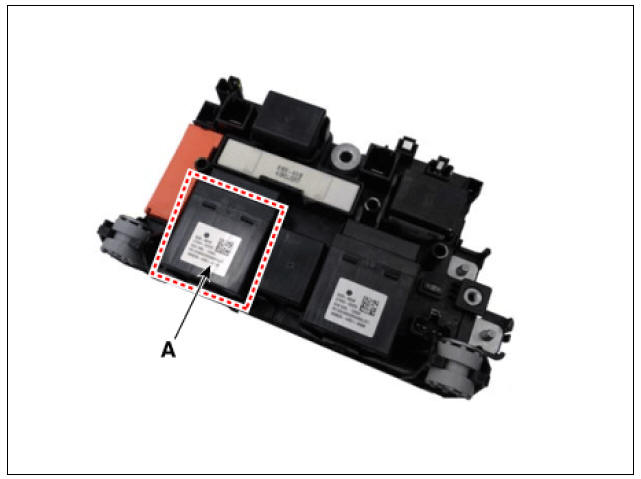

- Remove the main relay (A).

Main Relay (+)

Main Relay (-)

Installation

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to read and follow the "High Voltage Shut-off Procedures" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Install the main relay in the reverse order of removal.

Inspection

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to read and follow the "High Voltage Shut-off Procedures" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

Checking for Welding in the High Voltage Main Relay

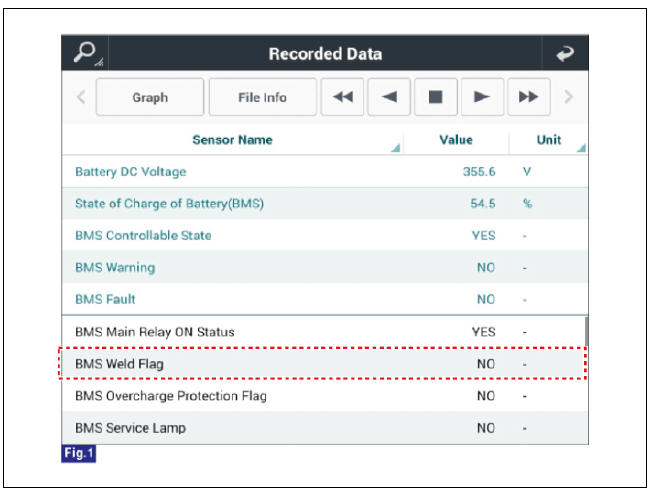

Using KDS service data to check for main relay weld damage

- Connect the KDS to the Data Link Connector (DLC).

- Turn the ignition switch ON.

- Check the BMS weld damage state in the KDS service data.

Using a Multimeter to measure weld damage

- Shut off the high voltage.

(Refer to "High Voltage Shut-off Procedures")

- Remove the high voltage battery rear cover.

(Refer to "High Voltage Battery System - "Case")

- Remove the inlet cooling duct.

(Refer to Hybrid Control System - "Cooling Duct")

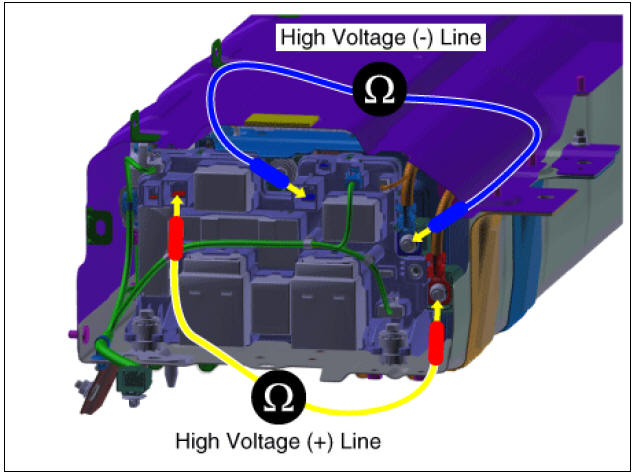

- Measure the high voltage main relay resistance and check for signs of weld damage.

Specification : ∞Ω (20ºC (68ºF))

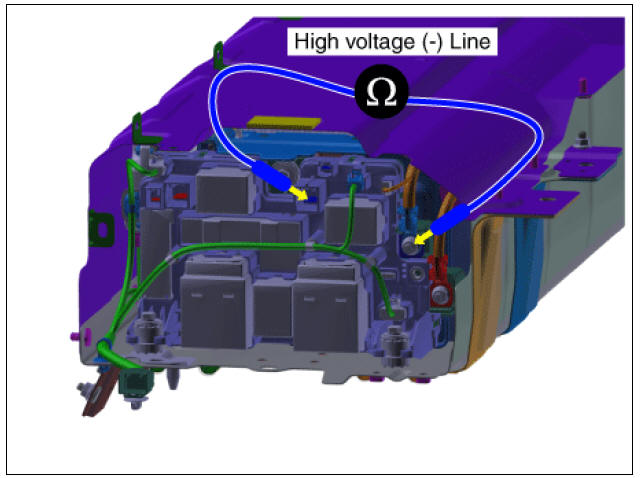

High voltage main relay (-) switch resistance

- Shut off the high voltage.

(Refer to "High Voltage Shut-off Procedures")

- Remove the high voltage battery rear cover.

(Refer to "High Voltage Battery System - "Case")

- Remove the inlet cooling duct.

(Refer to Hybrid Control System - "Cooling Duct")

- Measure the resistance between the high voltage power terminal (-) and the inverter power terminal (-).

Circuit inspection (Relay ON)

Warning

Inspect the high voltage main relay (-) activated by KDS.

- Connect the KDS to the Data Link Connector (DLC).

- Turn the ignition switch ON.

- Activate the main relay by using "Actuation Test" on the KDS as shown in the illustration below.

Warning

When the relay is ON, there is a relay operation sound.

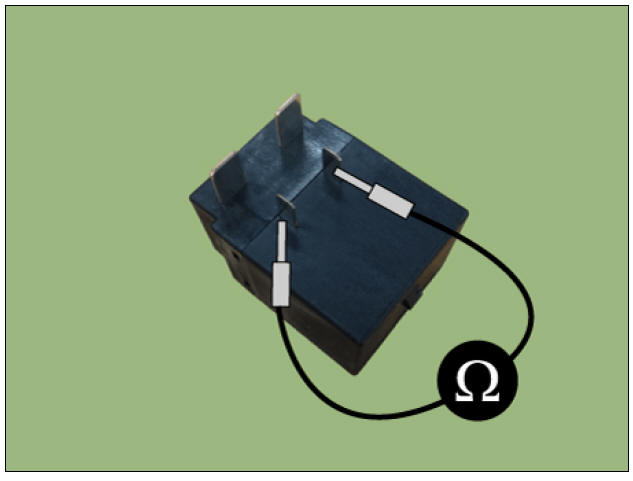

High Voltage Main Relay Coil Resistance

- Shut off the high voltage.

(Refer to "High Voltage Shut-off Procedures")

- Remove the power relay assembly.

(High Battery System - "Power Relay Assembly")

- Check for continuity between the terminals using an ohmmeter.

READ NEXT:

High Voltage Battery Cooling

High Voltage Battery Cooling

Component

Location

Cooling Fan #1

Cooling Fan #2

Main High Voltage Battery Cooling Duct (Inlet)

Main High Voltage Battery Cooling Duct (Outlet)

Sub High Voltage Battery Cooling Duct (Inlet)

Sub High Voltage Battery Cooling Duct (Ou

Cooling Fan - Components and components location

Cooling Fan - Components and components location

Components

Cooling Fan #1

BLDC Motor

Main Connector

Cooling Fan #2

BLDC Motor

Main Connector

Removal

Warning

Be sure to read and follow the "General Safety Information and

Caution" before doing any work re

Cooling Fan Repair procedures

Cooling Fan Repair procedures

Installation

Warning

Be sure to read and follow the "General Safety Information and

Caution" before doing any work related with the high voltage system. Failure

to follow the safety

instructions may result in serious electrical

SEE MORE:

Brake fluid

Brake fluid

Checking brake fluid level (Kia NIRO Hybrid)

Checking brake fluid level (Kia Niro EV)

Operation

Clean the area around the reservoir

cap.

Periodically check that the fluid level

in the brake fluid reservoir is between

MIN and MAX

Hitches

Hitches

It's important to have the correct hitch

equipment. Crosswinds, large trucks

going by, and rough roads are a few reasons

why you'll need the right hitch.

Here are some rules to follow:

Do you have to make any holes in the

body of

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us