KIA Niro: Driveshaft and axle

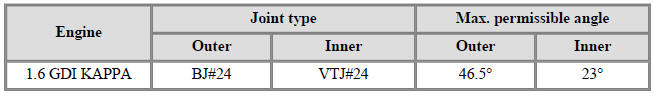

Service Data

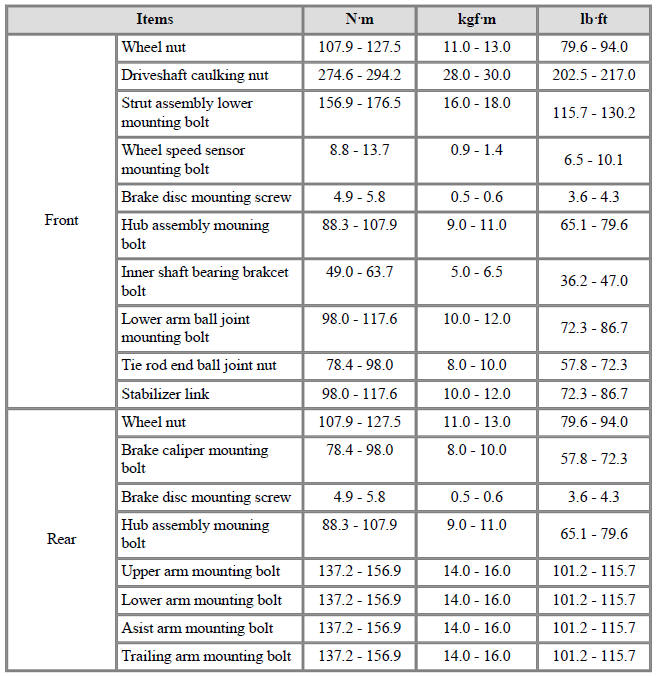

Tightening Torques

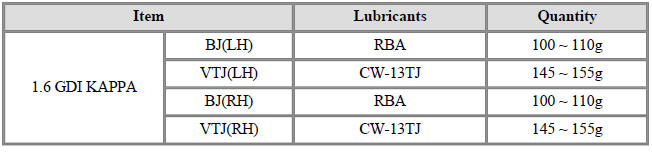

Lubricants

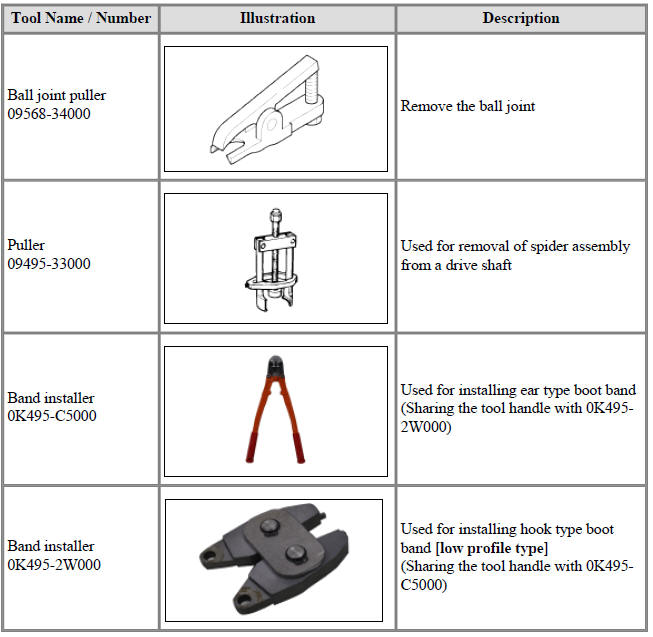

Special Service Tools

Tool Name / Number/ Illustration/ Description

Ball joint puller

09568-34000/  / Remove the ball

joint

/ Remove the ball

joint

Puller

09495-33000/  /Used for removal of

spider assembly

/Used for removal of

spider assembly

from a drive shaft

Band installer

0K495-C5000/  /Used for installing

ear type boot band

/Used for installing

ear type boot band

(Sharing the tool handle with 0K495-

2W000)

Band installer

0K495-2W000/  /Used for installing

hook type boot

/Used for installing

hook type boot

band (low profile type)

(Sharing the tool handle with 0K495-

C5000)

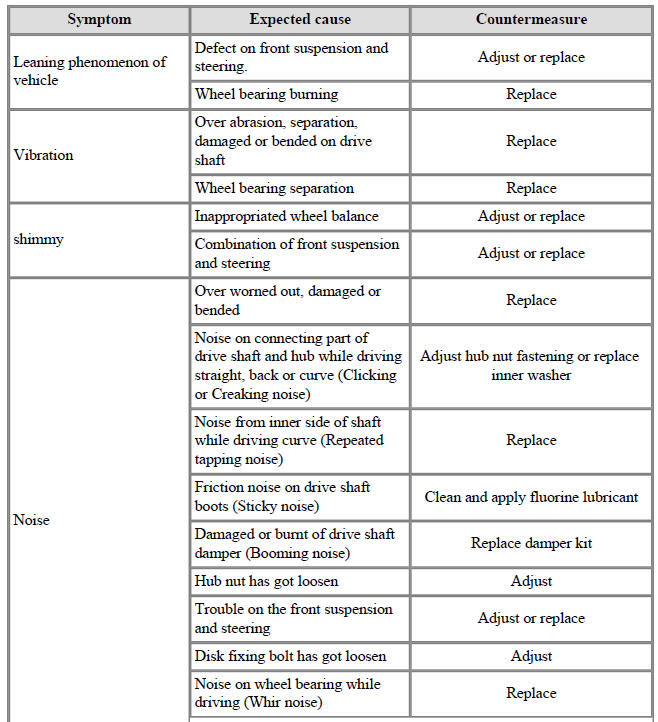

Troubleshooting

Symptom:

Leaning phenomenon of vehicle

Expected cause → Countermeasure

Defect on front suspension and steering. → Adjust or replace

Wheel bearing burning → Replace

Symptom:

Vibration

Expected cause → Countermeasure

Over abrasion, separation, damaged or bended on drive shaft → Replace

Wheel bearing separation → Replace

Symptom:

shimmy

Expected cause → Countermeasure

Inappropriated wheel balance → Adjust or replace

Combination of front suspension and steering → Adjust or replace

Symptom:

Noise

Expected cause → Countermeasure

Over worned out, damaged or bended → Replace

Noise on connecting part of drive shaft and hub while driving straight, back or curve (Clicking or Creaking noise) → Adjust hub nut fastening or replace inner washer

Noise from inner side of shaft while driving curve (Repeated tapping noise) → Replace

Friction noise on drive shaft boots (Sticky noise) → Clean and apply fluorine lubricant

Damaged or burnt of drive shaft damper (Booming noise) → Replace damper kit

Hub nut has got loosen → Adjust

Trouble on the front suspension and steering → Adjust or replace

Disk fixing bolt has got loosen → Adjust

Noise on wheel bearing while driving (Whir noise) → Replace

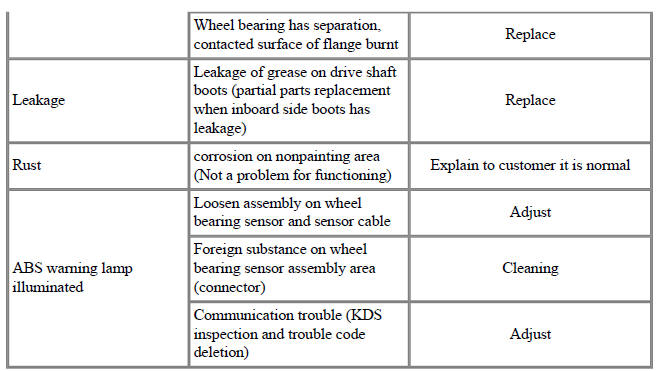

Wheel bearing has separation, contacted surface of flange burnt → Replace

Symptom:

Leakage

Expected cause → Countermeasure

Leakage of grease on drive shaft boots (partial parts replacement when inboard side boots has leakage) → Replace

Symptom:

Rust

Expected cause → Countermeasure

corrosion on nonpainting area (Not a problem for functioning) → Explain to customer it is normal

Symptom:

ABS warning lamp

illuminated

Expected cause → Countermeasure

Loosen assembly on wheel bearing sensor and sensor cable → Adjust

Foreign substance on wheel bearing sensor assembly area (connector) → Cleaning

Communication trouble (KDS inspection and trouble code deletion) → Adjust

READ NEXT:

Front Driveshaft Repair procedures

Front Driveshaft Repair procedures

Component location

Inner shaft bearing bracket

Drive shaft (RH)

Drive shasft (LH)

Front Driveshaft Repair procedures

Removal

Remove the wheel and tire.

Tightening torque:

107.9 - 127.5 N*m (11.0 - 13.0 kgf*m, 79.6 - 94.0 lb*ft

TJ Joint Repair procedures

TJ Joint Repair procedures

Removal

Warning

Drive shaft joints require special grease, so do not add any

other type of grease.

When replacing the boot band, it must be a new one.

Remove the front drive shaft.

(Refer to Driveshaft Assembly - "Front Drive

SEE MORE:

Fuel Pressure Control Valve (FPCV)

Fuel Pressure Control Valve (FPCV)

Specification

Fuel Pressure Control Valve (FPCV) Description

Description

Installed on the high pressure fuel pump, the Fuel Pressure Control Valve

controls the flow of fuel into

the injectors in accordance with the ECM signal calculated ba

Climate control system components

Climate control system components

A: Outside air

B: Recirculated air

C: Climate control air filter

D: Blower

E: Evaporator core

F: Heater core

The climate control air filter installed

behind the glove box filters the dust or

other pollutants that come into the v

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us