KIA Niro: Front Driveshaft Repair procedures

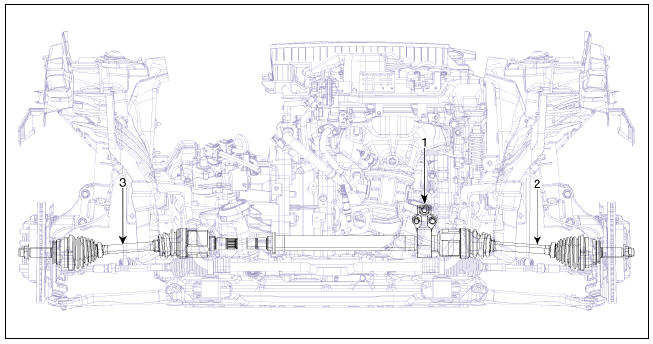

Component location

- Inner shaft bearing bracket

- Drive shaft (RH)

- Drive shasft (LH)

Front Driveshaft Repair procedures

Removal

- Remove the wheel and tire.

Tightening torque: 107.9 - 127.5 N*m (11.0 - 13.0 kgf*m, 79.6 - 94.0 lb*ft)

Warning

Be careful not to damage the wheel nuts when removing the wheel and tire.

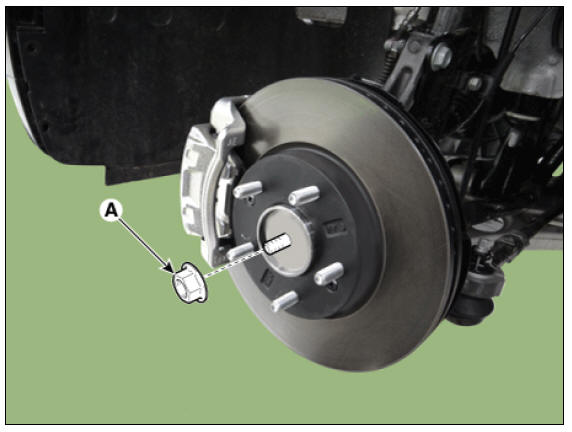

- By hammering on a chisel, unlock the driveshaft lock hub nut caulking.

Warning

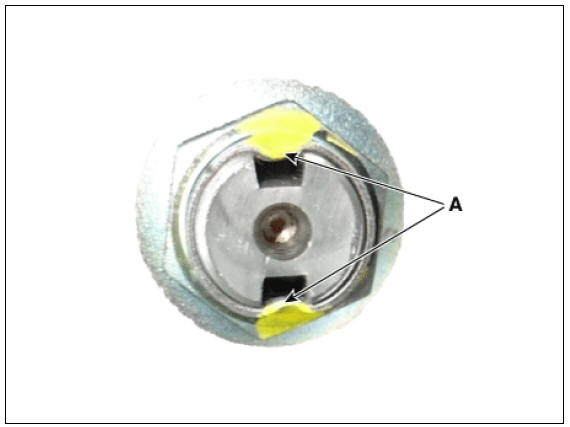

If there is screw thread (A) on the end of the nut, unlock the

caulking by using a chisel and then loosen the nut

to prevent damaging driveshaft screw thread.

- Remove the caulking nut (A) from the front axle.

Tightening torque: 274.6 - 294.2 N*m (28.0 - 30.0 kgf*m, 202.5 - 217.0 lb*ft)

Warning

The driveshaft lock nut must be replaced with new one. When

replacing the drive lock hub nut, use only the

nut with screw thread (A) on the end

- Tighten the driveshaft lock hub nut to the specified tightening torque, and caulk by using a chisel and hammer.

- If there are two key seats, perform on all two seats.

Caulking depth (A) : 1.5 mm (0.0591 in)

- Remove the under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

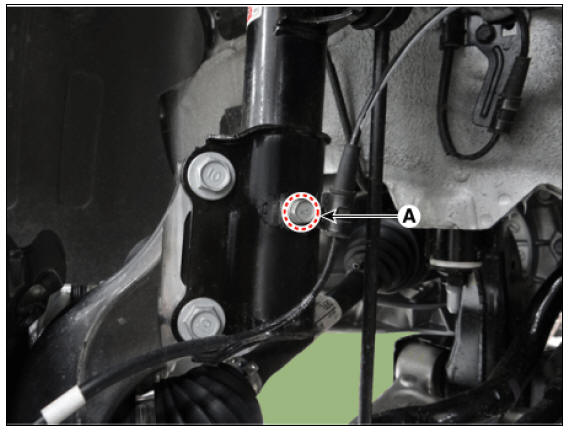

- Remove the wheel speed sensor bolt (A).

Tightening torque : 6.8 - 10.7 N*m (0.7 - 1.1 kgf*m, 5.0 - 7.9 lb*ft)

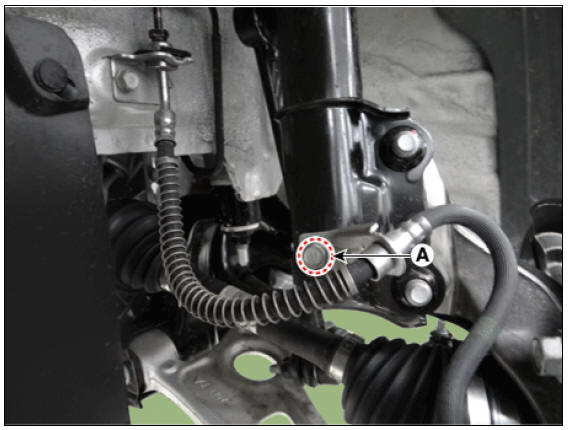

- Remove the wheel speed sensor bracket bolt (A).

Tightening torque : 8.8 - 13.7 N*m (0.9 - 1.4 kgf*m, 6.5 - 10.1 lb*ft)

- Remove the caliper hose bracket bolt (A).

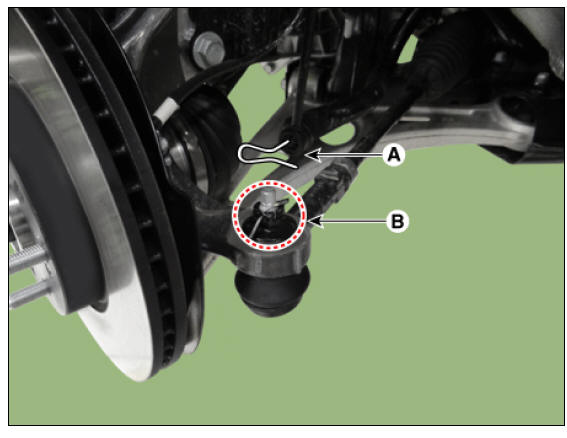

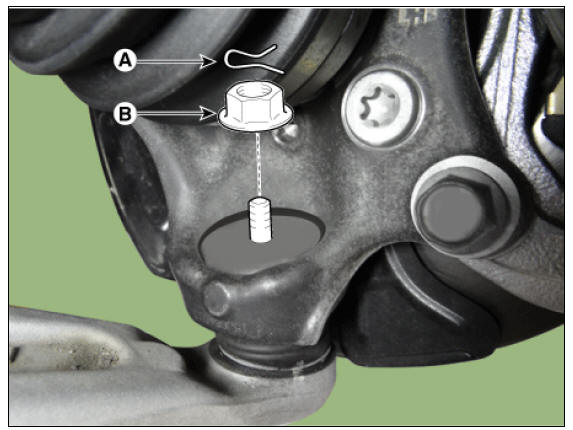

- Remove the tie rod end pin (A) and nub (B).

Tightening torque : 78.4 - 98.0 N*m (8.0 - 10.0 kgf*m, 57.8 - 72.3 lb*ft)

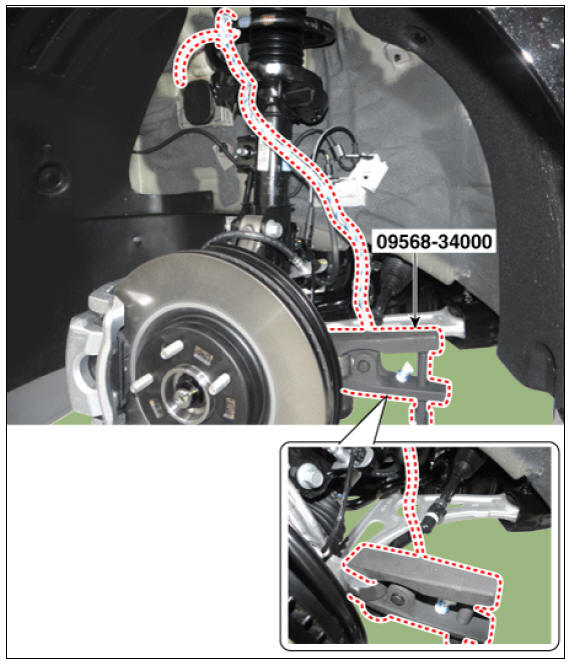

- Remove the knuckle by using the SST (09568-34000).

- Remove the lower arm pin (A) and nut (B).

Tightening torque : 78.4 - 98.0 N*m (8.0 - 10.0 kgf*m, 57.8 - 72.3 lb*ft)

- Remove the stabilizer link nut.

Tightening torque : 98.0 - 117.6 N*m (10.0 - 12.0 kgf*m, 72.3 - 86.7 lb*ft)

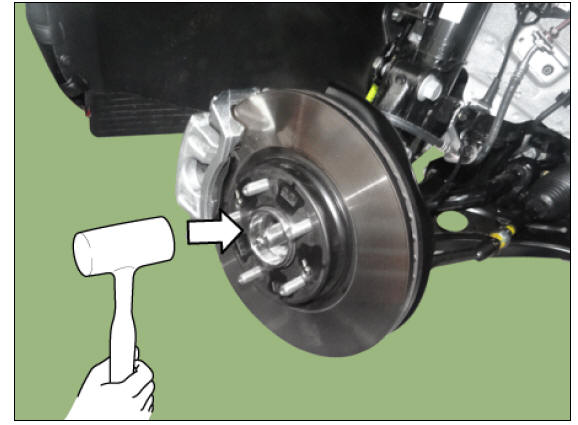

- Using a plastic hammer, disconnect driveshaft from the axle hub.

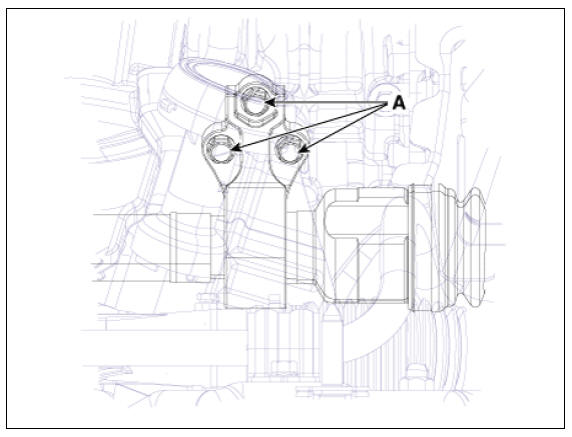

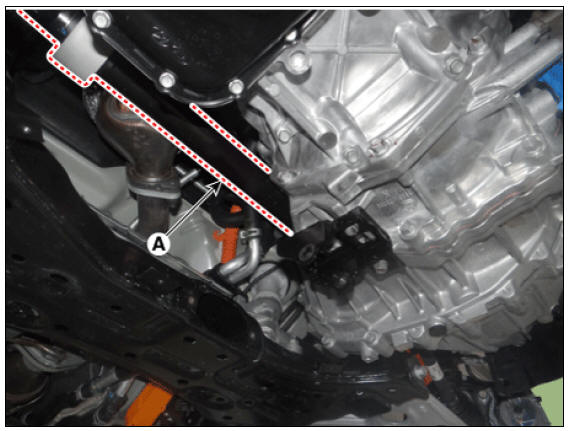

- Remove the iner shaft bearing bracket bolt (A).

Tightening torque : 49.0 - 63.7 N*m (5.0 - 6.5 kgf*m, 36.2 - 47.0 lb*ft)

- Remove the drive shaft (A).

Warning

If the drive shaft could not be ejected, remove the pry bar through the space between transmission and drive shaft.

- Install in the reverse order of removal.

Warning

- Use a pry bar being careful not to damage the transaxle and joint.

- Do not insert the pry bar too deep, as this may cause damage to the oil seal.

- Do not pull the driveshaft by excessive force it may cause components inside the joint kit to dislodge resulting in a torn boot or a damaged bearing.

- Plug the hole of the transaxle case with the oil seal cap to prevent contamination.

- Support the driveshaft properly.

- Replace the retainer ring whenever the driveshaft is removed from the transaxle case.

READ NEXT:

TJ Joint Repair procedures

TJ Joint Repair procedures

Removal

Warning

Drive shaft joints require special grease, so do not add any

other type of grease.

When replacing the boot band, it must be a new one.

Remove the front drive shaft.

(Refer to Driveshaft Assembly - "Front Drive

Driveshaft Assembly

Driveshaft Assembly

Removal

The type can replace the wheel side joint boot

Remove the front driveshaft.

(Refer to Driveshaft Assembly - "Front driveshaft")

Remove the transaxle side joint.

(Refer to Driveshaft Assembly - "Joint Assembly(Tra

Front Hub / Knuckle

Front Hub / Knuckle

Components

Brake disc

Hub assembly

Dust cover

Knuckle

Front Hub / Knuckle / Repair Procedures

Removal

Remove the wheel and tire.

Tightening torque :

107.9 - 127.5 N*m (11.0 - 13.0 kgf*m, 79.6 - 94.0 lb*ft)

Warning

Be c

SEE MORE:

Dual Clutch Assembly

Dual Clutch Assembly

Components

Retaining ring

Spline hub

Snap ring

Dual clutch assembly

Dual Clutch Assembly Repair procedures

Removal

Remove the hybrid drive motor & dual clutch transmission assembly from

the vehicle.

(Refer to DCT Syst

Checking the inverter coolant level (HEV)

Checking the inverter coolant level (HEV)

If frequent additions are required, we

recommend that the system be

inspected by a professional workshop.

Kia recommends to visit an authorized

Kia dealer/service partner.

The inverter coolant level should be in

between MAX and MIN when the

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us