KIA Niro: Fly Wheel Repair procedures

Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual / Engine Mechanical System / Cylinder Block / Fly Wheel Repair procedures

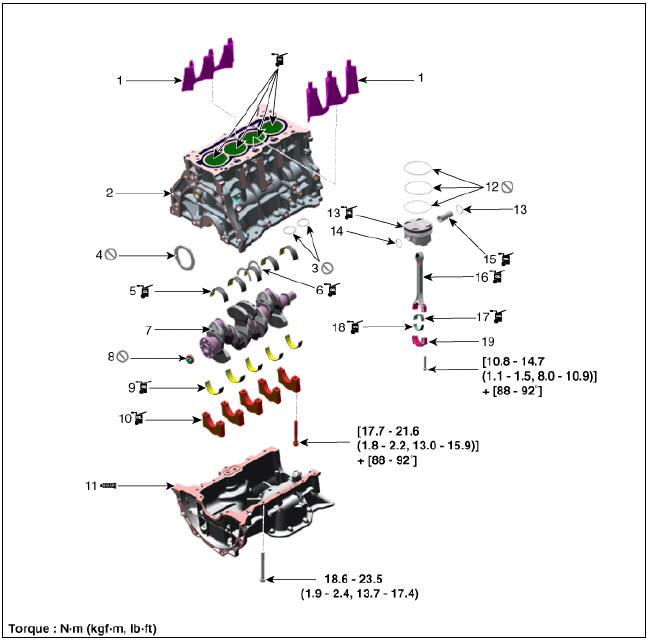

Components

- Water jacket insert

- Cylinder block

- Oil ring

- Rear oil seal

- Crankshaft upper bearing

- Thrust bearing

- Crankshaft

- Pilot bearing

- Crankshaft lower bearing

- Crankshaft lower bearing cap

- Ladder frame

- Piston ring

- Piston

- Snap ring

- Piston pin

- Connecting rod

- Connecting rod upper bearing

- Connecting rod lower bearing

- Connecting rod bearing cap

Fly Wheel Repair procedures

Removal and Installation

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to shut off the high voltage circuit according to the "High Voltage Shut-off Procedures" before doing any work related with the high voltage system to avoid serious electrical injuries

- Shut off the high voltage circuit.

(Refer to Engine Mechanical System - "High Voltage Shut off Procedure")

- Remove the dual clutch transmission.

(Refer to Double Clutch Transmission (DCT) - "Double Clutch Transmission Assembly")

- Remove the engine clutch disk and clutch cover.

(Refer to Engine Clutch System - "Clutch Cover and Disk")

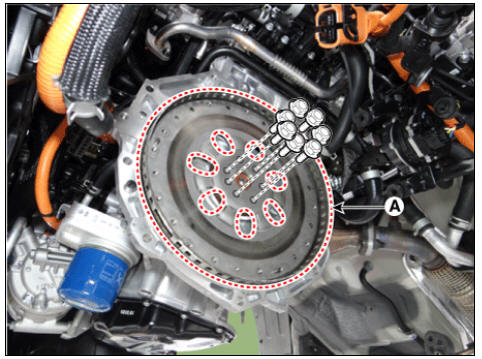

- Remove the flywheel (A).

Tightening torque : 78.5 - 88.3 N*m (8.0 - 9.0 kgf*m, 57.9 - 65.1 lb*ft)

Warning

Always use new flywheel bolts.

- Install in the reverse order of removal.

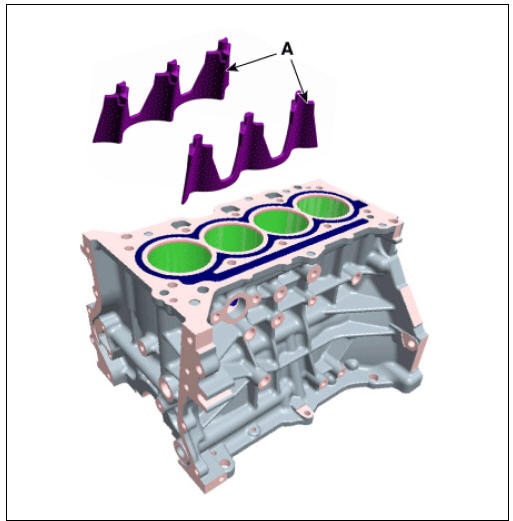

Water Jacket Insert Repair procedures

Removal and

Installation

- Remove the cylinder head.

(Refer to Cylinder Head Assembly - "Cylinder Head")

- Remove the water jacket insert (A).

- Install in the reverse order of removal.

READ NEXT:

Rear Oil Seal Repair procedures

Rear Oil Seal Repair procedures

Replacement

Warning

Be sure to read and follow the "General Safety Information and

Caution" before doing any

work related with the high voltage system. Failure to follow the safety

instructions may result in

serious electrical injuries

Piston and Connecting Rod Repair procedures

Piston and Connecting Rod Repair procedures

Disassembly

Warning

Be sure to read and follow the "General Safety Information and

Caution" before doing any work related

with the high voltage system. Failure to follow the safety instructions may

result in serious electrical

injuries

Connecting Rod

Connecting Rod

Check the connecting rod side clearance.

Using a feeler gauge, measure the end play while moving the connecting rod

back and forth.

If out-of-tolerance, install a new connecting rod.

If still out-of-tolerance, replace the crankshaft.

SEE MORE:

Warning timing/ Warning volume

Warning timing/ Warning volume

Warning timing

A: Driving Safety

Forward Safety Warning Timing

Normal

Late

With the vehicle on, touch Settings →

Driver Assistance → Driving Safety →

Forward Safety Warning Timing on

the instrument cluster or Settings →

Muffler Repair procedures

Muffler Repair procedures

Muffler Components and components location

Components

Front muffler

GPF

Center muffler

Rear muffler

Gasket

Rubber hanger

Muffler Repair procedures

Removal and

Installation

Front Muffler

Disconnect the heated oxygen sensor

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us