KIA Niro: Front Stabilizer Bar

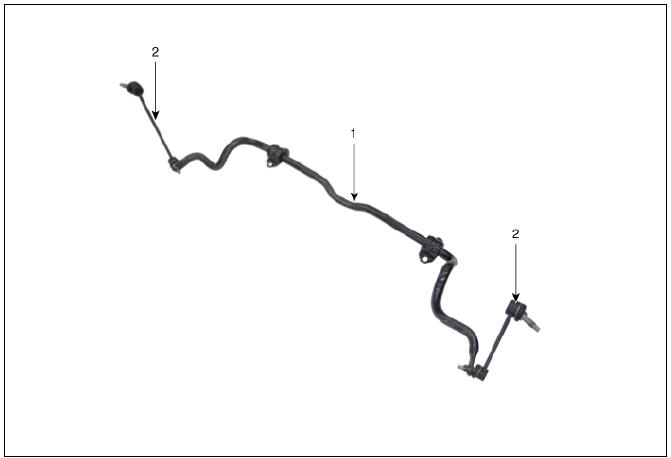

Front Stabilizer Bar Components and components location

- Stabilizer bar

- Stabilizer link

Front Stabilizer Bar Repair procedures

Removal

- Disconnect the battery negative cable.

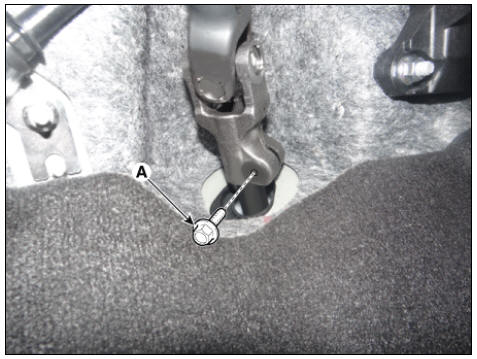

- Remove the universal bolt (A).

Tightening torque : 32.4 - 37.3 N*m (3.3 - 3.8 kgf*m, 23.9 - 27.5 lb*ft)

Warning

- Keep neutral range to prevent damaging the clock spring inner cable when steering the wheel.

- Do not reuse the bolt.

- Remove the wheel and tire.

Tightening torque: 107.9 - 127.5 N*m (11.0 - 13.0 kgf*m, 79.6 - 94.0 lb*ft)

Warning

Be careful not to damage the wheel nuts when removing the wheel and tire.

- Remove the under cover.

(Refer to Engine Mechanical System - "Engine Room Under Cover")

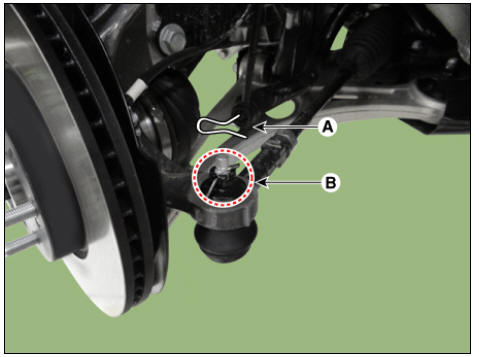

- Remove the tie rod end pin (A) and nub (B).

Tightening torque: 78.4 - 98.0 N*m (8.0 - 10.0 kgf*m, 57.8 - 72.3 lb*ft)

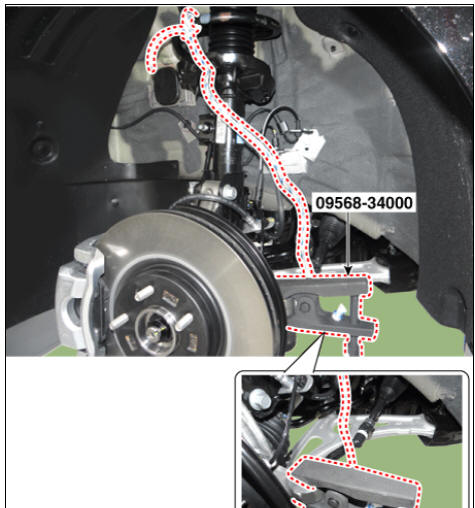

- Remove the knuckle by using the SST (09568-34000).

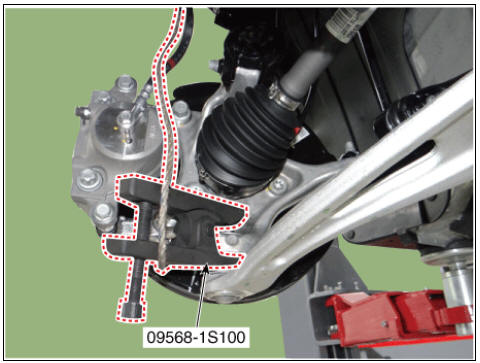

- Disconnect the lower arm from the knuckle by using the SST (09568-1S100).

(1) Remove the lower arm pin (A) and nut (B).

Tightening torque : 78.5 - 98.1 N*m (8.0 - 10.0 kgf*m, 57.9 - 72.3 lb*ft)

(2) Disconnect the lower arm from the knuckle by using the SST (09568-1S100).

Warning

- When using SST, be sure not to damage the dust cover of lower arm ball joint.

- Keep SST tied to the car because there is a risk of injury by dropping the SST during removing the lower arm ball joint.

- The peripheral parts may be damaged when removing the lower arm ball joint with a general tool such as lever, so be sure to use SST.

- Remove the stabilizer link nut.

Tightening torque: 98.0 - 117.6 N*m (10.0 - 12.0 kgf*m, 72.3 - 86.7 lb*ft)

- Loosen the nuts and then remove the heat protector.

- Remove the hanger (A).

- Remove the roll rod bracket.

(Refer to Engine Mechanical System - "Engine Mounting")

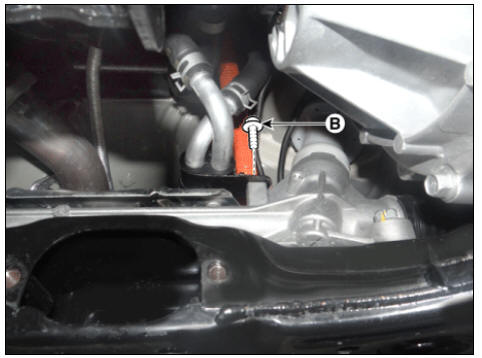

- Loosen the bolts (A) and (B) and then remove the coolant pipe.

Tightening torque: 6.8 - 10.7 N*m (0.7 - 1.1 kgf*m, 5.0 - 7.9 lb*ft)

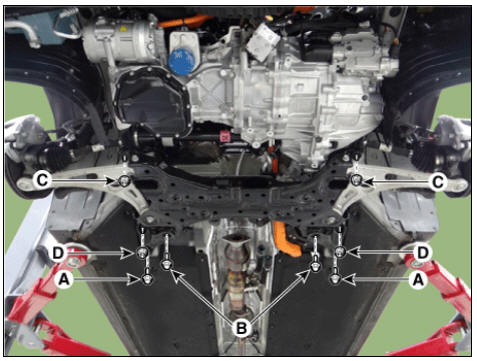

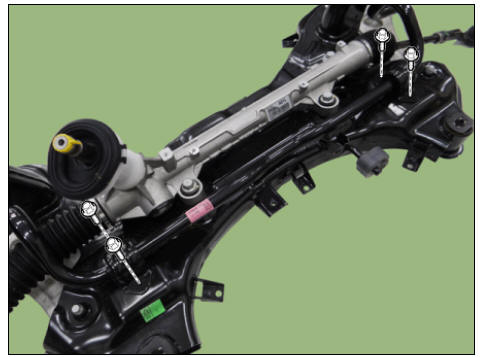

- Loosen the bolts (A,B) and nuts (C,D) and then remove the sub frame (D).

Tightening torque: Bolts : (A) 44.1 - 53.9 N*m (4.5 - 5.5 kgf*m, 32.5 - 39.8 lb*ft) (B) 176.5 - 196.1 N.m (18.0 - 20.0 kgf.m, 130.2 - 144.6 lb-ft) Nuts : (C) 176.5 - 196.1 N.m (18.0 - 20.0 kgf.m, 130.2 - 144.6 lb-ft) (D) 44.1 - 53.9 N*m (4.5 - 5.5 kgf*m, 32.5 - 39.8 lb*ft)

Warning

Set up the transmission jack under the subframe in order to remove the shock absorber in no-load condition .

- Loosen the bolts and then remove the gearbox heat protector.

- Loosen the bolts and then remove the front stabilizer bar.

Tightening torque: 44.1 - 53.9 N*m (4.5 - 5.5 kgf*m, 32.5 - 39.8 lb*ft)

- Install in the reverse order of removal.

- Check the wheel alignment.

(Refer to Suspension System - "Alignment")

Inspection

- Check the bushing for wear and deterioration.

- Check the front stabilizer bar for deformation.

- Check the front stabilizer link ball joint for damage.

READ NEXT:

Sub Frame Repair procedures

Sub Frame Repair procedures

Removal

Disconnect the battery negative cable.

Remove the universal bolt (A).

Tightening torque :

32.4 - 37.3 N*m (3.3 - 3.8 kgf*m, 23.9 - 27.5 lb*ft)

Warning

Keep neutral range to prevent damaging the clock spring inner

cable w

Rear Shock Absorber Repair procedures

Rear Shock Absorber Repair procedures

Rear Suspension System / Components And Components Location

Stabilizer bar

Rear sub frame

Rear upper arm

Rear shock absorber

Rear axle

Assist arm

Trailing arm

Coil spring

Rear Shock Absorber Repair procedures

Removal

Dis

SEE MORE:

Power Windows / Description And Operation

Power Windows / Description And Operation

Power Windows / Components And Components Location

Driver power window switch

Assist power window switch

Rear power window switch

Front window motor

Rear window motor

Power Windows / Description And Operation

Power Window Sa

Battery capacity label (Kia Niro EV / Hybrid)

Battery capacity label (Kia Niro EV / Hybrid)

Battery capacity label

Example

* The actual battery label in the vehicle

may differ from the illustration.

The Kia model name of battery

The nominal capacity (in Ampere

hours)

The nominal reserve capacity (in min.)

The nominal voltag

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us