KIA Niro: Heated Oxygen Sensor (HO2S)

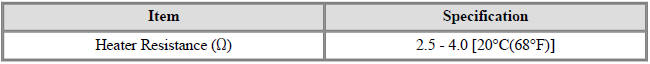

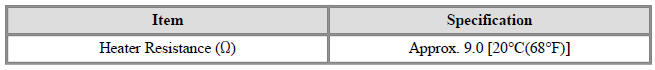

Specification

HO2S (Bank 1/Sensor 1) (Linear)

HO2S (Bank 1/Sensor 2) (Binary type)

Description

Heated Oxygen Sensor (HO2S), consisting of zirconium and alumina, is

installed on both upstream

and downstream of the Manifold Catalytic Converter (MCC) to detect the air/fuel

ratio and send it to

the ECM. The sensor output voltage varies in accordance with the air/fuel ratio.

The sensor must be hot in order to operate normally. To keep it hot, the sensor

has a heater which is

controlled by the ECM via a duty cycle signal. When the exhaust gas temperature

is lower than the

specified value, the heater warms the sensor tip.

Inspection

- Switch "OFF" the ignition.

- Disconnect the HO2S connector.

- Measure resistance between the HO2S terminals 4 and 5 (B1/S1).

Specification: 2.5 - 4.0Ω (20ºC(68ºF))

- Measure resistance between the HO2S terminals 3 and 4 (B1/S2).

Specification: Approx. 9.0 Ω (21ºC(69.8ºF))

- Check that the resistance is within the specification.

Removal

Warning

Note that the SST (Part No.: 09392-1Y100 or 09392-2H100) can be used for removing the heated oxygen sensor.

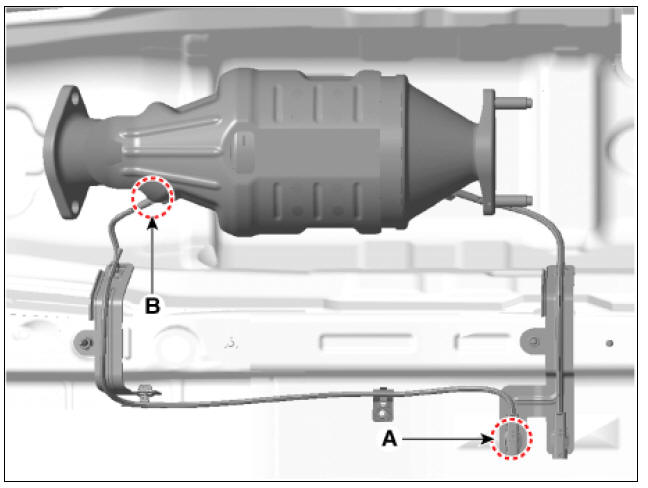

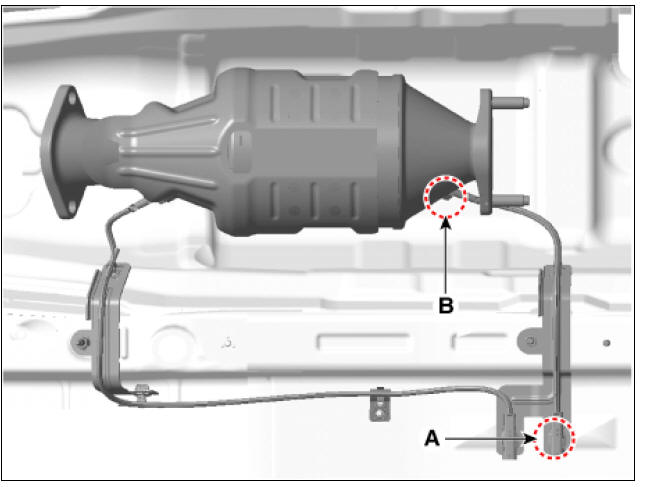

Bank 1 / Sensor 1

- Switch "OFF" the ignition and disconnect the negative (-) battery terminal.

- Disconnect the connector (A), and then remove the sensor (B).

Heated oxygen sensor : 39.2 - 49.1 N*m (4.0 - 5.0 kgf*m, 28.9 - 36.2 lb*ft)

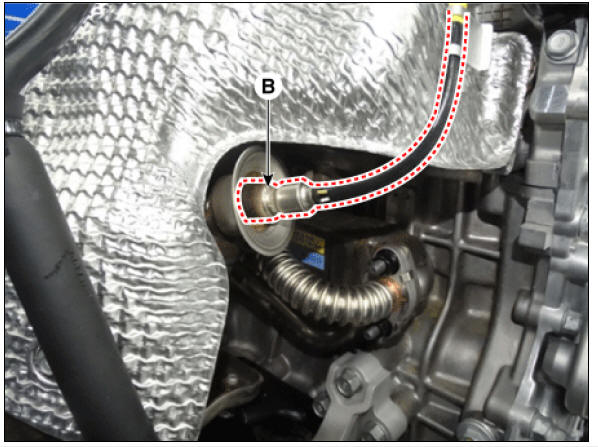

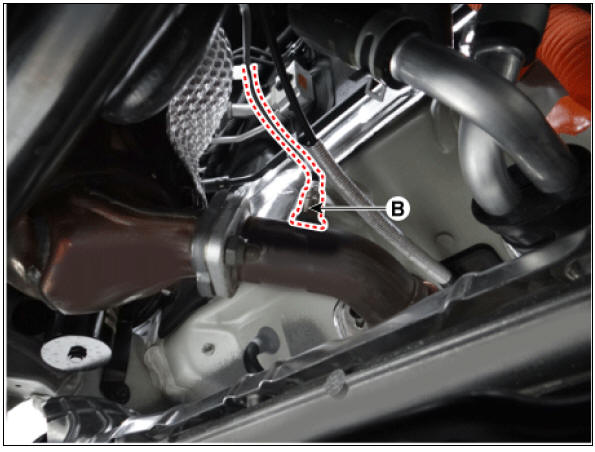

Bank 1 / Sensor 2

- Switch "OFF" the ignition and disconnect the negative (-) battery terminal.

- Disconnect the connector (A), and then remove the sensor (B).

Heated oxygen sensor : 39.2 - 49.1 N*m (4.0 - 5.0 kgf*m, 28.9 - 36.2 lb*ft)

Installation

Warning

- Install the component to the specified torque.

- Note that internal damage may occur when the component is dropped. If the component has been dropped, inspect before installing.

Warning

- Keep the sensing element and connector free from cleaner, spray or grease as oil substance may cause the sensor to malfunction.

- Sensor and its wiring may get damaged from contact with the exhaust system (e.g. Exhaust Manifold, Catalytic Converter).

- Install in the reverse order of removal.

Description

Installed in exhaust manifold, the Exhaust Gas Temperature Sensor (EGTS) #1

for EWGA senses the

temperature of exhaust gas flowing into the EWGA.

Installed in Gasoline Particulate Filter (GPF) assembly, the Exhaust Gas Temperature Sensor (EGTS) #2 for DPF senses the temperature of exhaust gas flowing into the GPF.

When predetermined engine condition is met, ECM burns soot collected in DPF with exhaust gas.

During this, the exhaust gas temperature is an important factor of engine condition.

Specification

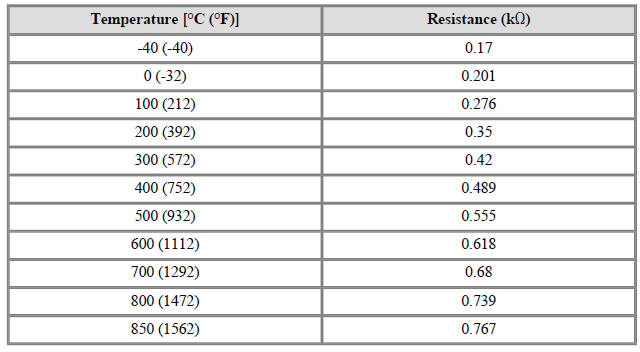

Exhaust Gas Temperature Sensor (EGTS) #1, 2

- Type : Thermistor type

Circuit Diagram

EGTS #1

Harness Connector

EGTS #2

Harness Connector

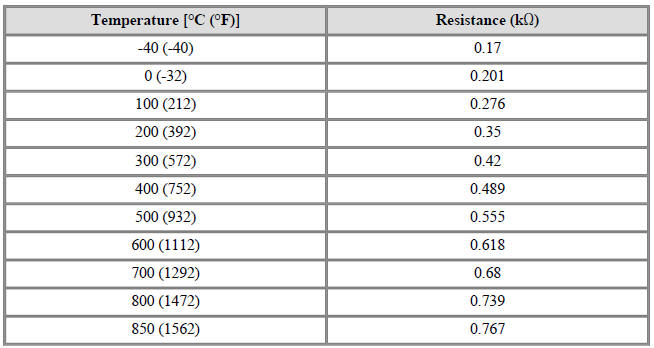

Inspection

- Turn ignition switch OFF.

- Disconnect the connector of exhaust gas temperature sensors #1/#2.

- Measure resistance between sensor signal terminal and ground terminal.

- Check that the resistance is within the specification.

Exhaust Gas Temperature Sensor (EGTS #1, #2 (T3, T4))

Removal

EGTS #1 (T3)

- Turn the ignition switch OFF and disconnect the battery negative (-) terminal.

- Lift the vehicle.

- Disconnect the EGTS #1 connector (A).

- Remove the EGTS #1 (B).

EGTS #2 (T4)

- Turn the ignition switch OFF and disconnect the battery negative (-) terminal.

- Lift the vehicle.

- Disconnect the EGTS #2 connector (A).

- Remove the EGTS #2 (B).

Installation

Warning

- Install the component to the specified torques.

- Note that internal damage may occur when the component is dropped. In this case, use it after inspecting.

- Install in the reverse order of removal.

READ NEXT:

Rail Pressure Sensor (RPS)

Rail Pressure Sensor (RPS)

Specification

Rail Pressure Sensor (RPS) Description and operation

Description

Installed on the delivery pipe, the Rail Pressure Sensor (RPS) measures the

instantaneous fuel pressure

in the delivery pipe. The sensing element (Semiconduc

Accelerator Position Sensor (APS)

Accelerator Position Sensor (APS)

Specification

Accelerator Position Sensor (APS) Description and operation

Description

Installed on the accelerator pedal module, the Accelerator Position Sensor (APS)

detects the rotation

angle of the accelerator pedal. The APS is one o

Injector

Injector

Specification

Description

The GDI injector is similar to a standard injector, but sprays fuel at a much

higher pressure directly

into the combustion chamber and has a swirl disc to get the fuel swirling as it

exits the nozzle. This

aids i

SEE MORE:

Sub Battery Pack Assembly

Sub Battery Pack Assembly

Warning

Be sure to read and follow the "General Safety Information and

Caution" before doing any work related with the high

voltage system. Failure to follow the safety instructions may result in

serious electrical injuries.

Be sure to

How to disconnect charging connector in emergency

How to disconnect charging connector in emergency

Before disconnecting the charging

connector, make sure the doors are

unlocked. When the door is locked,

the charging connector lock system

will not allow disconnection. To prevent

charging cable theft, the

charging connector cannot be

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us