KIA Niro: Sub Battery Pack Assembly

Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual / Service Highlight / High Voltage Battery System / Sub Battery Pack Assembly

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to shut off the high voltage before doing any work related with the high voltage system(Refer to "High Voltage Shut-off Procedure"). Failure to follow the safety instructions may result in serious electrical injuries.

- Turn ignition switch OFF and disconnect the negative (-) battery terminal.

- Shut off the high voltage circuit.

(Refer to Hybrid Control System - "High Voltage Shut-off Procedures")

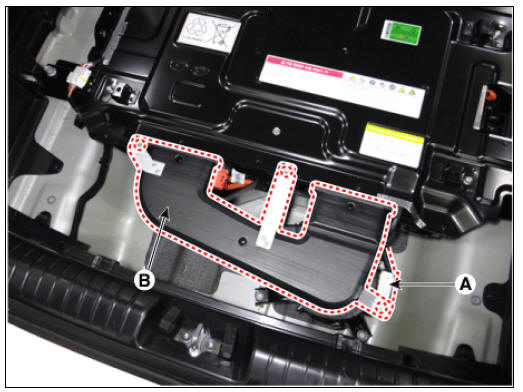

- Remove the high voltage rear cover (A) after loosening the mounting bolts.

High Voltage Battery Rear Cover mounting bolt : 7.8 - 11.8 N*m (0.8 - 1.2 kgf*m, 5.8 - 8.7 lb*ft)

- Remove the rear outlet cooling duct (B) after loosening bolts.

Rear Outlet Cooling Duct mounting bolt : 7.8 - 11.8 N*m (0.8 - 1.2 kgf*m, 5.8 - 8.7 lb*ft)

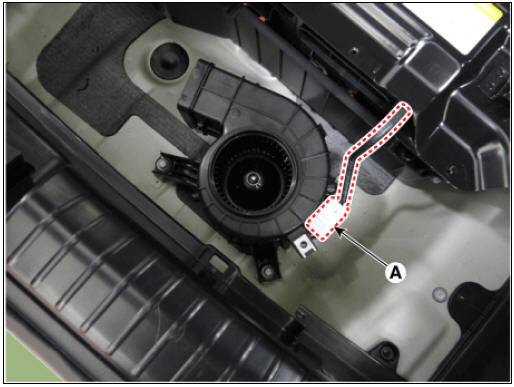

- Remove the cooling fan #2 connector (A).

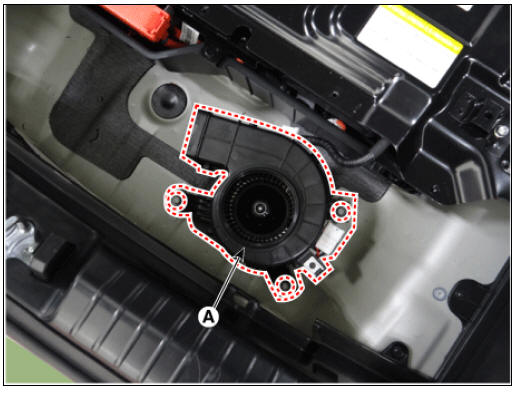

- Remove the cooling fan #2 (A) after loosening the mounting bolts.

Cooling Fan #2 mounting bolt : 7.8 - 11.8 N*m (0.8 - 1.2 kgf*m, 5.8 - 8.7 lb*ft)

- Disconnect the BMS ECU connector (A).

- Disconnect the high voltage cable connector (A) and BMS wiring harness connector (B) connected the main high voltage battery.

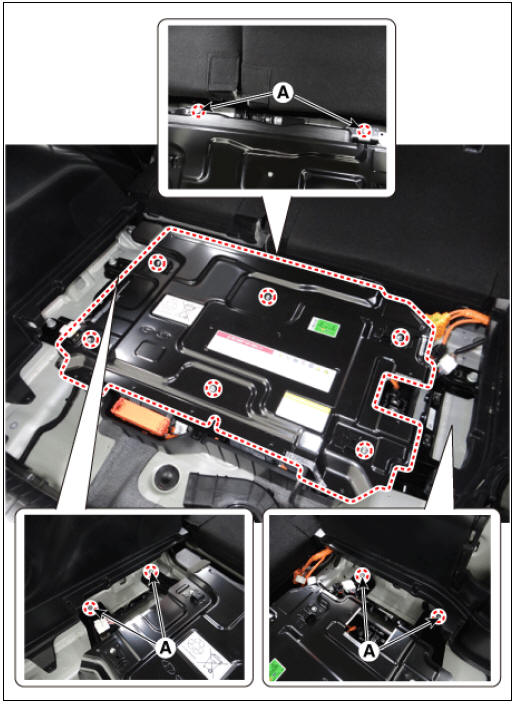

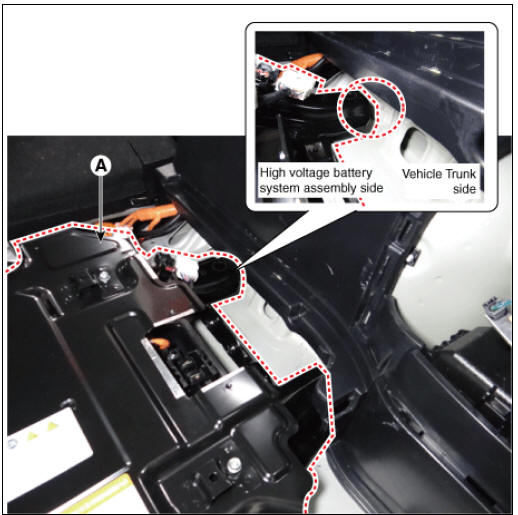

- Remove the sub high voltage battery system assembly mounting bolts (A).

Sub High Voltage Battery System Assembly mounting bolt : 54.9 - 82.4 N*m (5.6 - 8.4 kgf*m, 40.5 - 60.8 lb*ft)

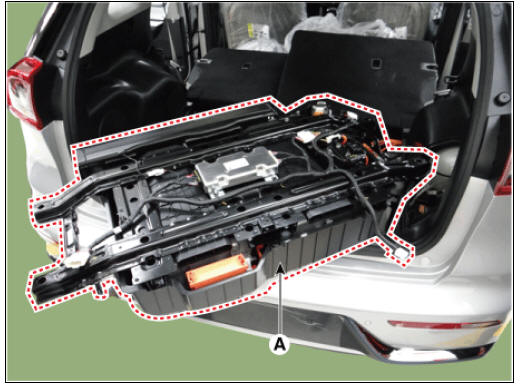

- Remove the sub high voltage batter system assembly (A).

Warning

Refer to the instructions below when removing the sub high voltage battery system because of tiny places to remove. Be careful not to damage on the interior trim or rear bumper when removing the battery.

- Push the sub high votlage battery system assembly (A) to the right as much as possible.

- Remove the high voltage battery system assembly from left side.

Installation

Warning

- Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Be sure to read and follow the "High Voltage Shut-off Procedures" before doing any work related with the high voltage system. Failure to follow the safety instructions may result in serious electrical injuries.

- Install the high voltage battery pack in the reverse order of removal.

READ NEXT:

Battery Pack Assembly Repair procedures

Battery Pack Assembly Repair procedures

Disassembly

Warning

Be sure to read and follow the "General Safety Information and

Caution" before doing any work related with the high

voltage system. Failure to follow the safety instructions may result in

serious electrical injuries.

Battery Pack Assembly Troubleshooting Chart

Battery Pack Assembly Troubleshooting Chart

Inspection

Warning

For SOC check, refer to "SOC Inspection"

For voltage check, refer to "Battery Voltage Inspection"

For battery voltage sensing circuit, refer to "Voltage Sensing

Circuit Inspection"

Fo

Power Relay Assembly (PRA)

Power Relay Assembly (PRA)

PRA Operation Sequence

Description

The Power Relay Assembly (PRA) consists of the positive and negative main

relays, pre-charge relay, pre-charge resistor and

battery current sensor. It is located inside the battery pack assembly and

controls

SEE MORE:

Vehicle weight

Vehicle weight

This section will guide you in the proper

loading of your vehicle, to keep your

loaded vehicle weight within its design

rating capability. Properly loading your

vehicle will provide maximum return of

the vehicle design performance. Before

loadi

Parking Brake Cable Repair procedures

Parking Brake Cable Repair procedures

Removal

Turn ignition switch OFF and disconnect the negative (-) battery

terminal.

Remove the crash pad lower panel.

(Refer to Body - "Crash Pad")

Remove the knee air bag.

(Refer to Restraint - "Knee Airbag(KAB) Module&q

Categories

- Home

- KIA Niro EV, Hybrid - Second generation - (SG2) (2021-2024) - Owner's manual

- Kia Niro - First generation - (DE) (2017-2022) - Service and Repair Manual

- Contact Us